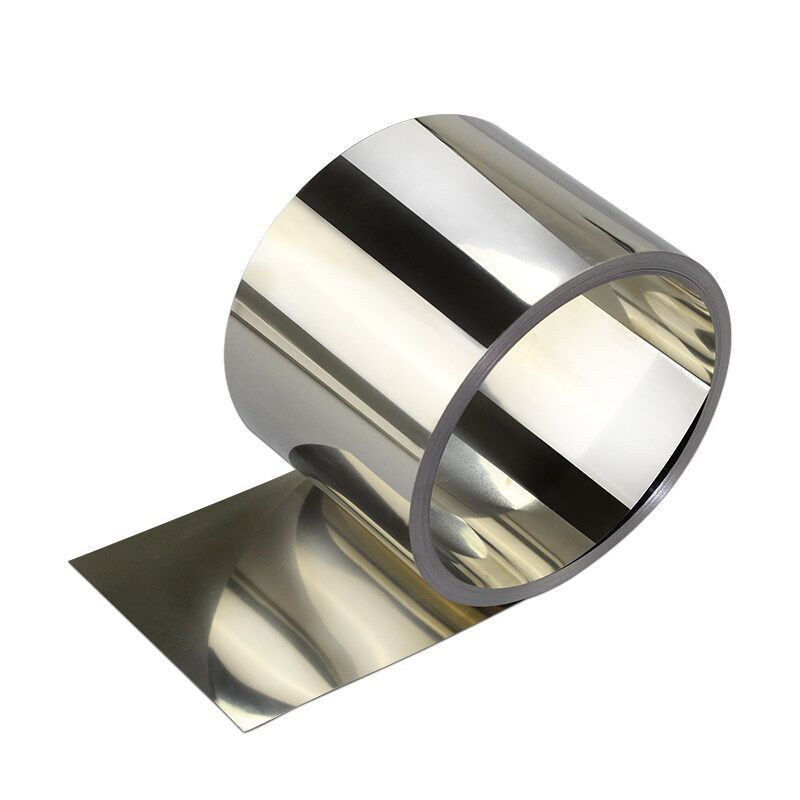

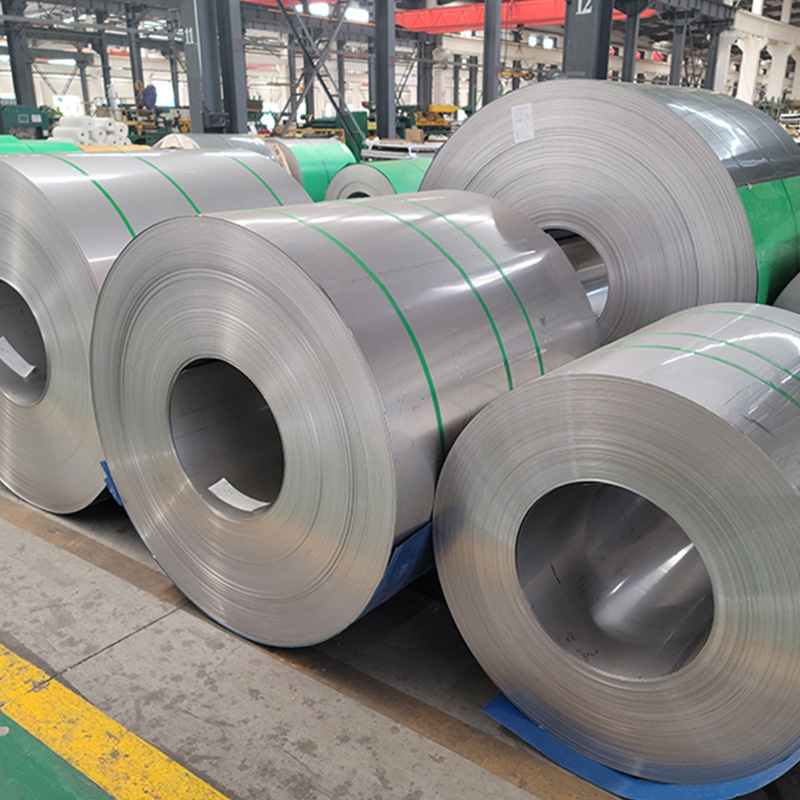

0Cr13Ni5Mo Coil

0Cr13Ni5Mo coil, a high-performance steel alloy, is a cutting-edge material that offers exceptional strength and corrosion resistance. It is a prime choice for a wide range of industrial applications due to its unique combination of properties.

0Cr13Ni5Mo belongs to the chromium-nickel-molybdenum family of steel alloys, which are renowned for their exceptional resistance to acids and alkalis. The 0Cr13Ni5Mo alloy, in particular, boasts superior mechanical properties, making it an excellent choice for applications that demand high tensile strength and ductility.

Exceptional corrosion resistance: The 0Cr13Ni5Mo steel alloy offers superior resistance to acids, alkalis, and other corrosive environments, making it an ideal choice for components that are constantly exposed to these substances.

High tensile strength: The material's impressive tensile strength ensures that it can withstand significant mechanical stress without compromising its integrity. This makes it suitable for applications where structural integrity is crucial, such as in the chemical processing, oil and gas, and power generation industries.

Ductility: The 0Cr13Ni5Mo steel alloy exhibits excellent ductility, which means it can be easily bent, shaped, and welded without cracking or fracturing. This characteristic further enhances its versatility in various manufacturing and engineering applications.

Temperature resistance: The steel's ability to withstand high temperatures makes it suitable for use in extreme heat environments, such as in furnaces or heat exchangers.

Easy to machine: 0Cr13Ni5Mo coil can be easily machined into various shapes and sizes, further enhancing its adaptability in different industrial settings.

Due to its exceptional corrosion resistance and mechanical properties, 0Cr13Ni5Mo coil finds widespread application in various industries:

Petroleum and natural gas: The oil and gas industry often operates in corrosive environments where pipelines, valves, and other components are constantly exposed to acids and other chemicals. 0Cr13Ni5Mo coil offers superior resistance to these substances, ensuring the durability and longevity of critical equipment.

Chemical processing: In the chemical processing industry, materials are often exposed to highly corrosive acids, alkalis, and other chemicals. The exceptional corrosion resistance of 0Cr13Ni5Mo coil makes it an ideal choice for components like reactors, tanks, piping systems, and other critical equipment.

Power generation: Power plants generate large amounts of heat and are often exposed to high-temperature environments. 0Cr13Ni5Mo coil's exceptional temperature resistance and mechanical properties make it suitable for use in heat exchangers, boilers, and other critical components in power generation facilities.

Automotive industry: The automotive industry demands materials that can withstand extreme corrosion and temperature exposure. 0Cr13Ni5Mo coil offers superior resistance to corrosion and can withstand the high temperatures associated with automotive manufacturing processes. It is suitable for use in automotive exhaust systems, fuel lines, and other critical components.

Manufacturing: In manufacturing industries, materials are often exposed to various corrosive substances and high temperatures during processing. 0Cr13Ni5Mo coil's exceptional corrosion resistance and temperature tolerance make it suitable for use in manufacturing processes where durability and longevity are essential. It can be used in various manufacturing applications such as in the production of machines, tools, and other industrial equipment.

In conclusion, 0Cr13Ni5Mo coil offers a unique combination of exceptional corrosion resistance, high tensile strength, ductility, temperature resistance, and ease of machining. These properties make it an excellent choice for a wide range of industrial applications where durability, reliability, and longevity are essential.

| C | Mn | Si | Cr | Ni | Mo | Al | P | S |

| ≤0.08% | ≤2.00% | ≤1.00% | 11.50 - 14.00% | 4.00 - 6.00% | 0.50 - 1.00% | ≤ 0.30% | ≤ 0.035% | ≤ 0.03% |

Mechanical Properties |

|

| The mechanical properties of 0Cr13Ni5Mo Coil are crucial for its performance in various applications. The key mechanical properties include yield strength, tensile strength, and impact toughness. Typical mechanical properties for 0Cr13Ni5Mo Coil are as follows: | |

| Yield Strength | ≥ 620 MPa (Typical) |

| Tensile Strength | ≥ 850 MPa (Typical) |

| Impact Toughness | ≥ 147 J (Typical) at -65°C |

| Application |

| The applications of 0Cr13Ni5Mo Coil are diverse and range from chemical processing equipment to offshore platforms and power generation components. The key applications of 0Cr13Ni5Mo Coil are as follows: |

| Chemical Processing Equipment: Due to its exceptional corrosion resistance, 0Cr13Ni5Mo Coil is widely used in the manufacturing of chemical processing equipment, including reactors and tanks. |

| Petroleum Refining: This coil is also commonly used in the petroleum refining industry, where it is employed in the production and storage of crude oil and refined products. It provides excellent corrosion resistance in the presence of acids and other corrosive agents found in the refining process. |

| Power Generation: In the power generation industry, 0Cr13Ni5Mo Coil is used in the manufacturing of components such as boiler tubes, heat exchangers, and steam generators. It offers excellent mechanical properties and longevity in high-temperature environments. |

| Offshore Platforms: This coil is also suitable for use in offshore platforms due to its high strength, corrosion resistance, and fatigue resistance. It can be used in the manufacturing of structural components, such as platform supports and pipelines. |