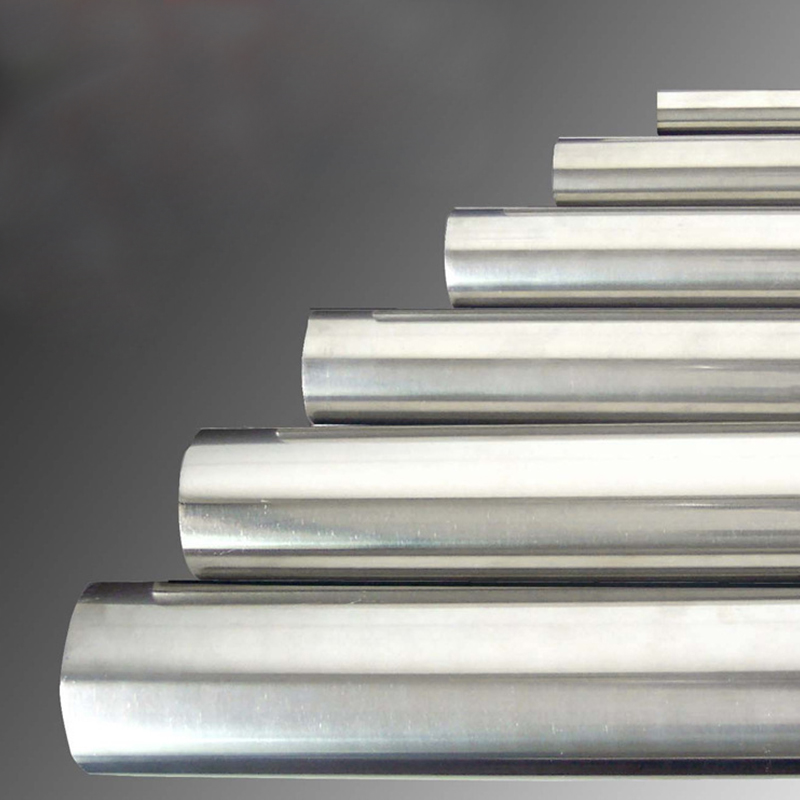

0Cr13Ni5Mo Pipe

In the world of high-performance alloys, 0Cr13Ni5Mo Pipe stands out as a paragon of strength and durability. This exceptional material, often utilized in extreme environments and high-stress applications, has become a go-to choice for engineers and fabricators seeking unparalleled longevity and reliability.

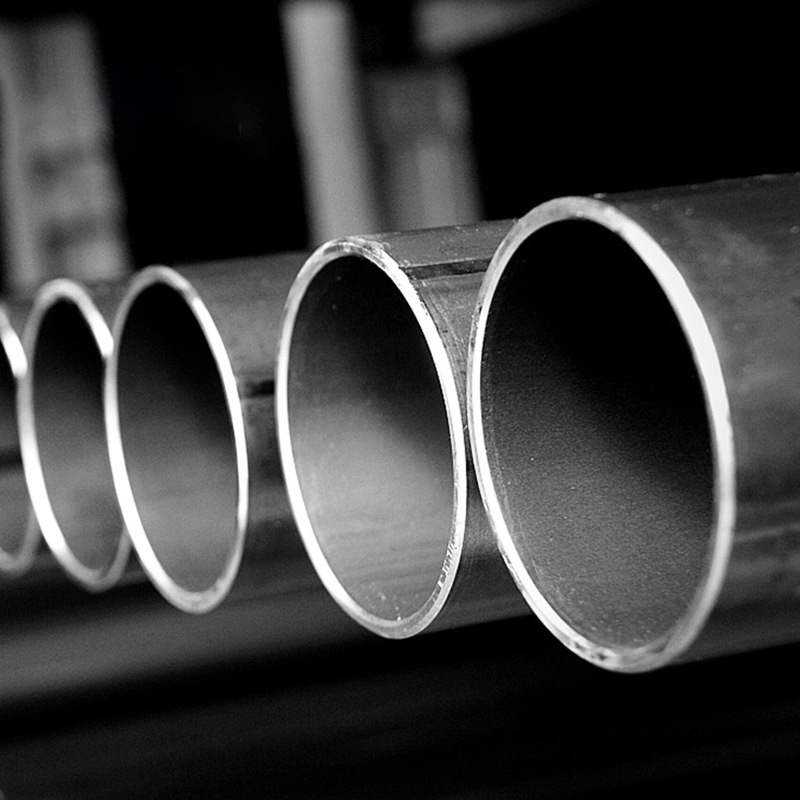

0Cr13Ni5Mo Pipe's unique composition offers a remarkable blend of properties. The 0% chromium content ensures exceptional resistance to corrosion, making it an excellent choice for use in corrosive environments. The addition of nickel and molybdenum further enhances the alloy's tensile strength and ductility, providing exceptional toughness and fatigue resistance.

The meticulous manufacturing process of 0Cr13Ni5Mo Pipe ensures its consistent quality and performance. This pipe is crafted using advanced techniques that guarantee its dimensional accuracy, surface finish, and mechanical properties. The end result is a product that offers unmatched performance, making it an exceptional choice for a wide range of industrial applications.

0Cr13Ni5Mo Pipe's adaptability and versatility are further testaments to its excellence. It can be used in a variety of industries, including oil and gas, chemical processing, power generation, and more. Its ability to withstand extreme temperatures and harsh environments makes it an invaluable asset in these industries, where reliability and durability are paramount.

In conclusion, 0Cr13Ni5Mo Pipe is more than just a material; it's a testament to innovation and excellence. Its unique properties, coupled with its adaptability and reliability, make it a top choice for engineers and fabricators around the world seeking to achieve the highest standards of performance in their respective industries.

| Product Name: 0Cr13Ni5Mo Pipe |

| Chemical Composition |

| C | Mn | Si | Cr | Ni | Mo | Al | P | S |

| ≤0.08% | ≤2.00% | ≤1.00% | 11.50 - 14.00% | 4.00 - 6.00% | 0.50 - 1.00% | ≤ 0.30% | ≤ 0.035% | ≤ 0.03% |

| Physical Properties | Specific Gravity(g/cm³): 8.02 |

| Melting Point(℃): 1400-1450℃ | |

| Linear expansion coefficient (℃) : 15 × 10-6 ℃ -1 | |

| Specific heat capacity (J/g ℃) : 460 | |

| Thermal conductivity coefficient (W/m ℃) : 16.3 | |

| Elastic modulus (GPa) : 200Mechanical Properties | |

| Tensile strength: ≥ 690 MPa | |

| Yield strength: ≥ 415 MPa | |

| Elongation: ≥ 35% | |

| Impact toughness: ≥ 47 J/cm2 (at -46℃) |