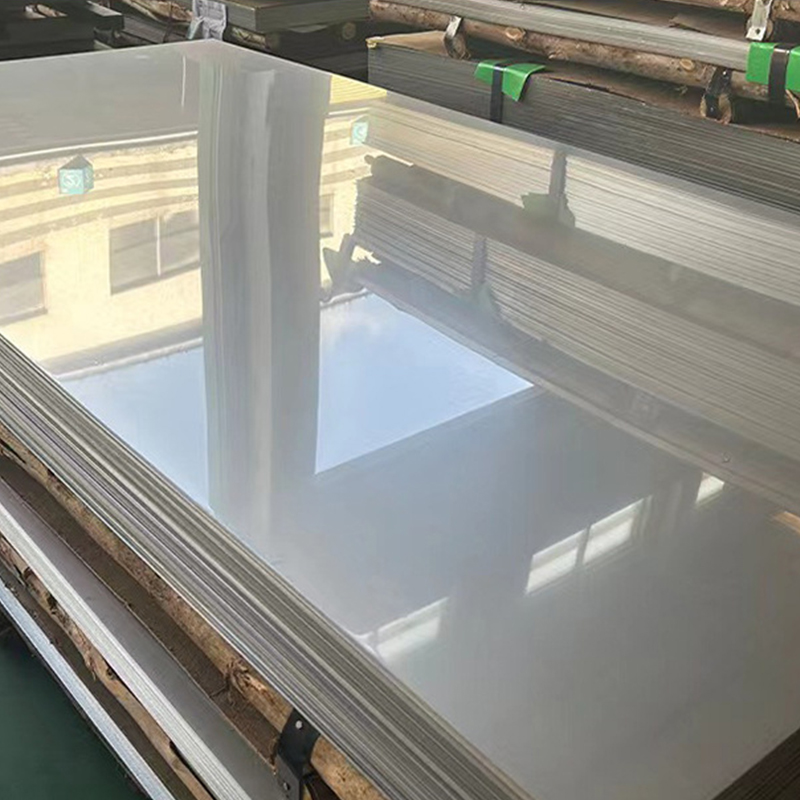

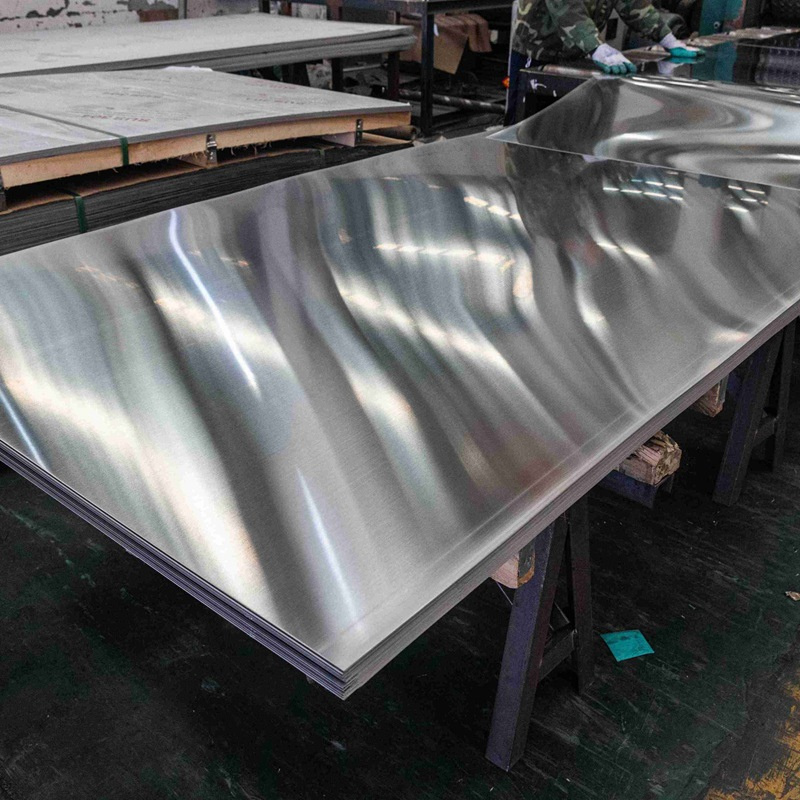

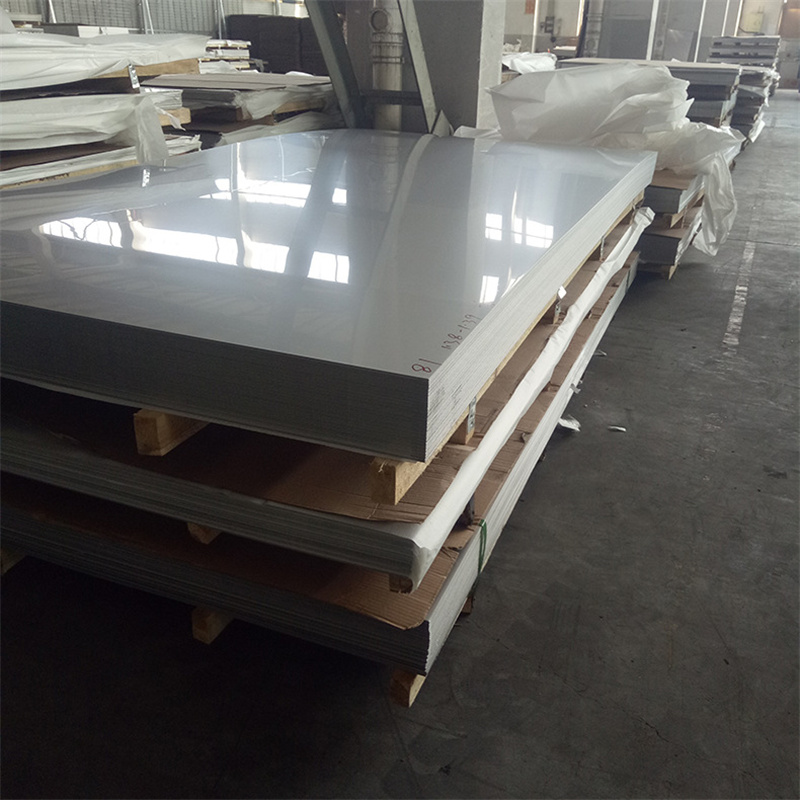

0Cr13Ni5Mo Plate

0Cr13Ni5Mo plate is a high-performance metal material, prized for its exceptional corrosion resistance, strength, and toughness. This plate is a prime choice for a wide range of industrial applications, thanks to its unique combination of properties.

The 0Cr13Ni5Mo alloy is a member of the chromium-nickel-molybdenum family, which has a long history of providing exceptional performance in extreme environments. It is carefully formulated to achieve an optimal balance of properties, making it suitable for use in demanding applications where corrosion resistance, strength, and ductility are critical.

The 0 in the alloy name indicates that carbon is the primary alloying element, contributing to the material's exceptional hardness and strength. The Cr, Ni, and Mo elements provide exceptional corrosion resistance, making 0Cr13Ni5Mo plate an excellent choice for use in corrosive environments.

0Cr13Ni5Mo plate is often used in the chemical processing industry, where it encounters various corrosive substances. It is also commonly used in the oil and gas industry, offshore platforms, and other marine environments. Its exceptional corrosion resistance and durability make it an excellent choice for these applications.

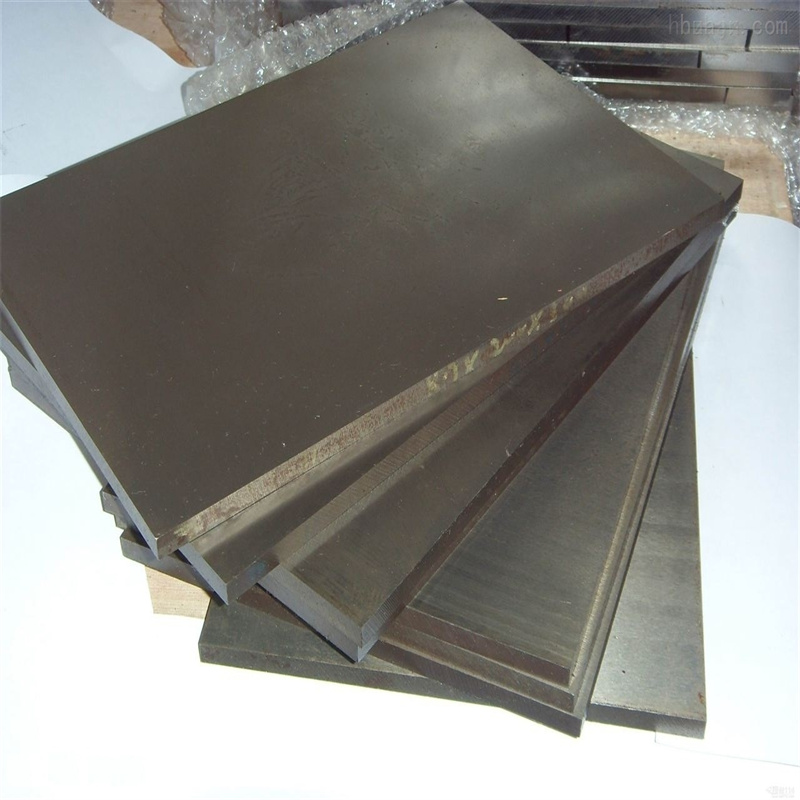

In addition to its corrosion resistance, 0Cr13Ni5Mo plate offers good mechanical properties. It has high strength and ductility, making it suitable for use in structural components and pressure vessels. The material's good fatigue resistance and toughness further enhance its versatility and make it suitable for use in dynamic applications where loads and stresses are constantly changing.

The processing of 0Cr13Ni5Mo plate is also important to consider. It can be fabricated using various techniques, such as welding, cutting, and bending. The material's good weldability makes it easy to join components, while its ductility allows for easy bending and forming. Proper processing parameters are essential to ensure that the material's properties are fully realized and that the final component meets the desired performance criteria.

0Cr13Ni5Mo plate is also suitable for use in a range of temperatures, making it suitable for cryogenic applications and high-temperature environments. Its good low-temperature toughness and elevated temperature strength make it an excellent choice for use in cryogenic tanks and other low-temperature applications. Its high-temperature strength and oxidation resistance also make it suitable for use in high-temperature furnaces and reactors.

In conclusion, 0Cr13Ni5Mo plate is a highly versatile metal solution that offers exceptional corrosion resistance, strength, toughness, and durability. Its unique combination of properties makes it suitable for a wide range of industrial applications, including those in the chemical processing industry, oil and gas industry, offshore platforms, marine environments, cryogenic tanks, high-temperature furnaces, and reactors. Its good processing characteristics and wide temperature range further enhance its versatility and make it an excellent choice for a range of demanding applications.

| Product Name: 0Cr13Ni5Mo Plate |

| Chemical Composition |

| C | Mn | Si | Cr | Ni | Mo | Al | P | S |

| ≤0.08% | ≤2.00% | ≤1.00% | 11.50 - 14.00% | 4.00 - 6.00% | 0.50 - 1.00% | ≤ 0.30% | ≤ 0.035% | ≤ 0.03% |

| Mechanical Properties | 0Cr13Ni5Mo Plate exhibits excellent mechanical properties, including high strength, good toughness and fatigue resistance. The tensile strength of the steel ranges from 690 to 910 MPa, with a yield strength of at least 580 MPa. The steel also has excellent impact toughness, with a Charpy V-notch impact energy of ≥60 J at -60 °C. |

| Corrosion Resistance | The corrosion resistance of 0Cr13Ni5Mo Plate is excellent, due to the presence of chromium and nickel in the alloy. The steel has good resistance to chloride stress corrosion cracking and crevice corrosion, making it suitable for use in harsh environments such as seawater and chemical processing plants. |