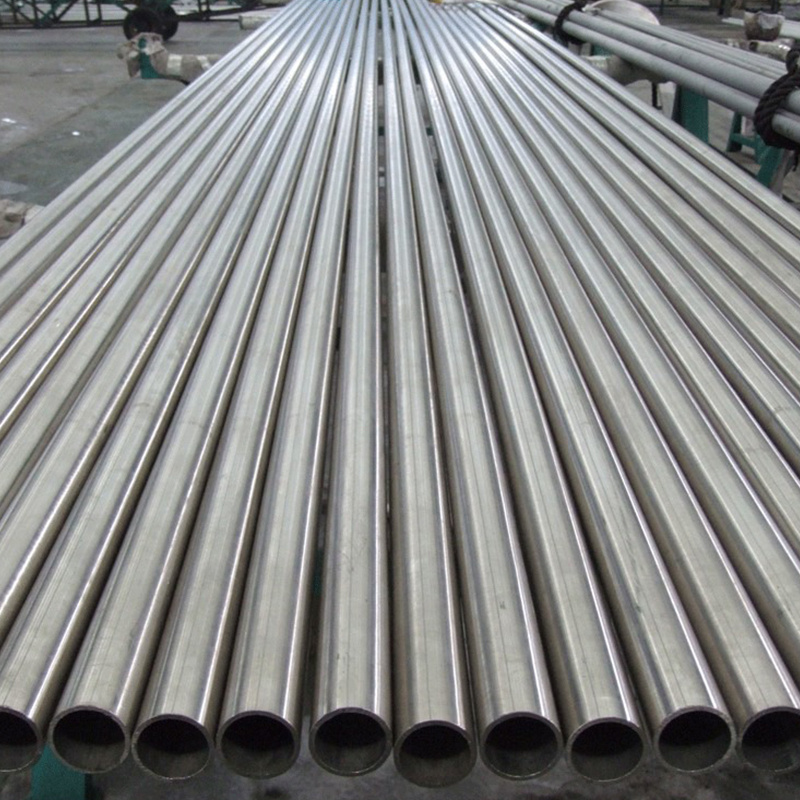

17-4PH Pipe

17-4PH Pipe, a high-performance nickel-copper alloy, is a widely used material in various industries due to its excellent corrosion resistance, strength, and ductility. With its unique combination of properties, 17-4PH Pipe offers exceptional value in various applications, particularly in corrosive environments.

Corrosion Resistance: 17-4PH Pipe's nickel-copper alloy composition provides excellent resistance to acids, alkalis, and other corrosive substances. This makes it an excellent choice for use in harsh environments where other materials would quickly corrode.

High Strength: 17-4PH Pipe offers significantly higher tensile strength than many other alloys. This added strength allows it to withstand greater stress and strain, making it suitable for use in demanding applications.

Ductility: Despite its high strength, 17-4PH Pipe also exhibits good ductility, allowing it to be easily formed and welded without compromising its mechanical properties. This combination of strength and ductility makes it an excellent choice for manufacturing components that require both strength and flexibility.

Temperature Resistance: 17-4PH Pipe has good resistance to high temperatures, making it suitable for use in applications where exposure to heat is unavoidable. Its ability to withstand high temperatures further enhances its versatility in various industrial applications.

Due to its exceptional corrosion resistance and combination of mechanical properties, 17-4PH Pipe is widely used in various industries and applications, including:

Chemical Processing: In the chemical processing industry, corrosion resistance is crucial. 17-4PH Pipe's exceptional corrosion resistance makes it an excellent choice for use in chemical tanks, pipelines, and other process equipment where exposure to corrosive chemicals is common.

Oil and Gas Exploration: In the oil and gas industry, pipelines are constantly exposed to harsh environments that can quickly corrode other materials. 17-4PH Pipe's exceptional corrosion resistance and high strength make it an ideal material for oil and gas pipelines, ensuring the longevity of these critical assets.

Power Generation: Power plants generate significant amounts of heat and are often exposed to corrosive substances. 17-4PH Pipe's high temperature resistance and corrosion resistance make it suitable for use in boiler components, heat exchangers, and other critical components in power generation systems.

Automotive Components: Automotive manufacturers often use 17-4PH Pipe for components that require both strength and corrosion resistance, such as exhaust systems and fluid handling components. Its good ductility allows it to be easily formed into complex shapes without compromising its mechanical properties.

Aerospace Applications: In the aerospace industry, materials must meet stringent performance standards. 17-4PH Pipe's combination of high strength, ductility, and corrosion resistance makes it suitable for use in aircraft components that require exceptional durability and reliability.

In conclusion, 17-4PH Pipe offers exceptional value in a wide range of industries due to its unique combination of corrosion resistance, strength, ductility, and temperature resistance. Its adaptability to various applications makes it a go-to material for manufacturers and engineers seeking to achieve superior performance in their products.

| Product Name: 17-4PH Pipe |

| C | Mn | Si | P | S | Cr | Ni | Cu | Mo | Al |

| 0.03 max | 1.00 max | 0.30 max | 0.04 max | 0.01 max | 15.00 -17.50 | 3.00 -5.00 | 3.50 -4.50 | 0.50 max | 0.10 max |

| Melting Point | Approximately 1850°F (1010°C). |

| Annealing Temperature | Typically between 1750°F and 2000°F (955°C to 1093°C). Annealing temperature can impact the final mechanical properties of the material. |

| Thermal Expansion | Similar to other stainless steels, 17-4PH exhibits thermal expansion characteristics that should be taken into account during design and manufacturing processes. |

| Mechanical Properties | The tensile strength of 17-4PH pipe ranges from 190 ksi to 220 ksi (1350 to 1500 MPa) depending on the annealing temperature and processing conditions. The yield strength typically ranges from 130 ksi to 160 ksi (890 to 1100 MPa). |

| Impact Strength | The material exhibits good impact toughness at cryogenic and room temperatures. |

| Formability | 17-4PH pipe can be easily formed or bent without cracking or wrinkling, provided appropriate forming techniques are used. |

| Surface Finish | The surface finish of 17-4PH pipe depends on the manufacturing process and post-processing operations. It can range from smooth mirror finish to a more textured satin finish. |