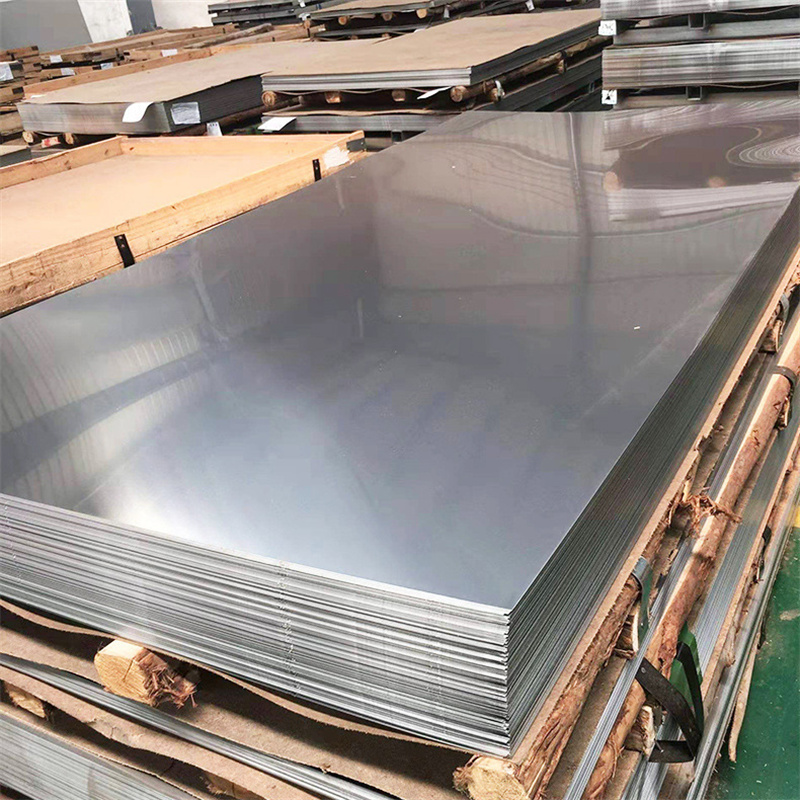

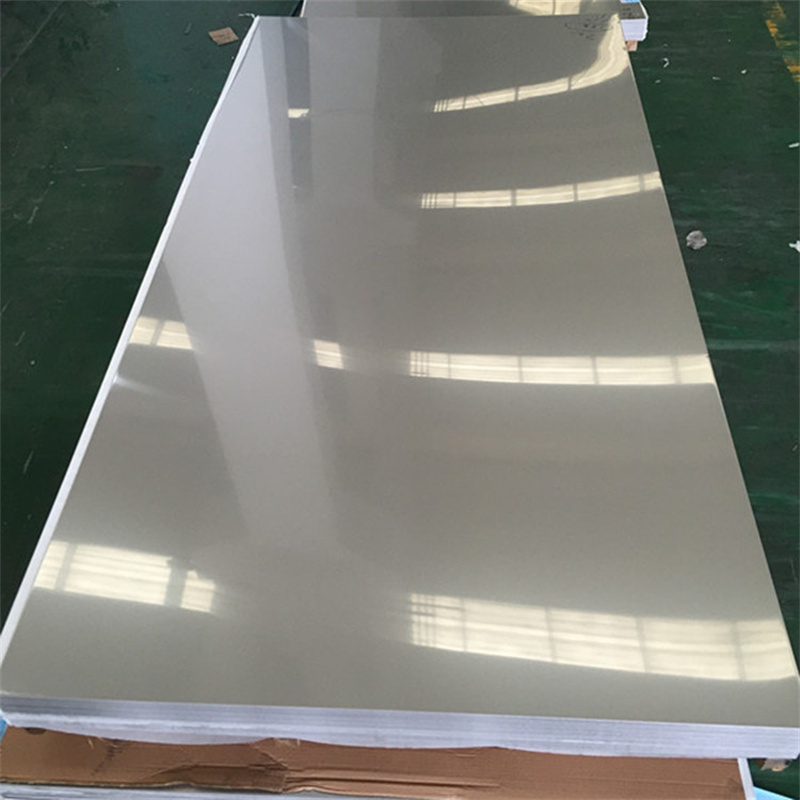

17-4PH Plate

17-4PH plate, also known as ZQSnPb10-10, is a high-performance material that combines the properties of stainless steel and copper. It is widely used in various industries due to its excellent corrosion resistance, high strength, and good processing performance.

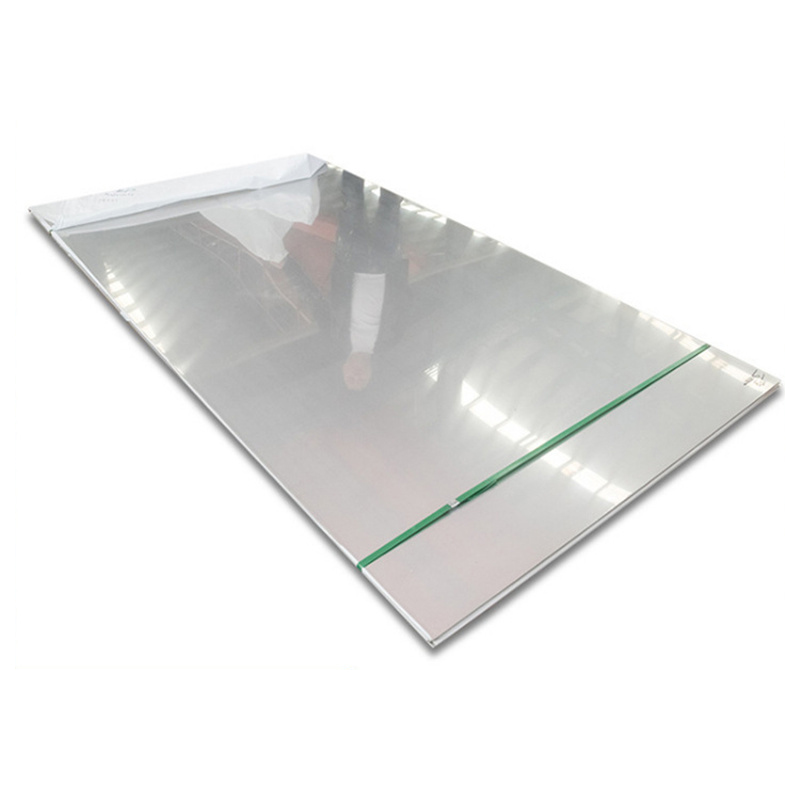

17-4PH plate is a precipitation-hardening stainless steel with a composition of 0.13% carbon, 3.0% nickel, 4.0% copper, 1.0% molybdenum, and the balance being iron. It has a yield strength of up to 170ksi (1100MPa) and a tensile strength of up to 220ksi (1450MPa). The material offers good fatigue resistance and is suitable for use in high-stress applications.

The corrosion resistance of 17-4PH plate is excellent. It has good resistance to acids, alkalis, and most organic solvents. It is also highly resistant to crevice corrosion and stress corrosion cracking. This makes it an ideal material for use in harsh environments, such as chemical processing plants, oil and gas pipelines, and power generation facilities.

The processing performance of 17-4PH plate is also excellent. It can be cut, welded, machined, and formed with ease. The material has good weldability and can be joined using various welding processes, such as gas tungsten arc welding (GTAW) and flux-cored arc welding (FCAW). It can also be joined using brazing or soldering processes.

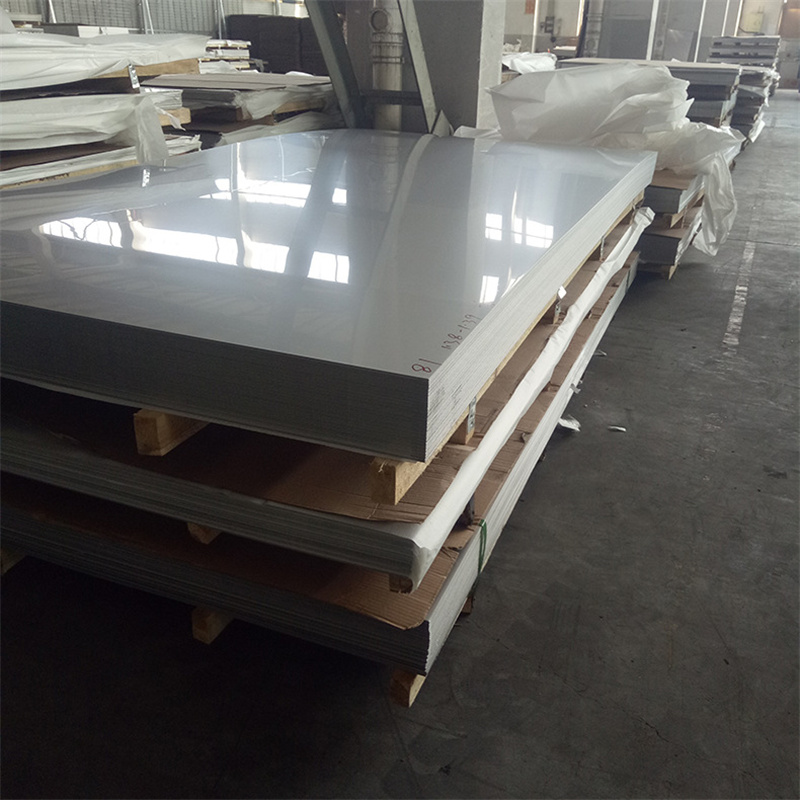

Applications of 17-4PH plate include aircraft components, automobile parts, medical equipment, chemical processing equipment, oil and gas pipelines, power generation equipment, and other high-performance applications that require good corrosion resistance and high strength.

In conclusion, 17-4PH plate is a high-performance material that offers excellent corrosion resistance, high strength, and good processing performance. It is widely used in various industries due to its versatility and reliability.

17-4PH (UNS S17400) is a precipitation-hardening stainless steel that offers good corrosion resistance, strength, and ductility. It has excellent weldability and can be heat treated to achieve desired mechanical properties. The material is commonly used in a variety of applications, including oil and gas exploration and production equipment, chemical processing equipment, and in other corrosive environments where high strength and durability are required.

17-4PH is precipitation-hardenable stainless steel with a ferrite-martensitic microstructure. It offers good corrosion resistance and can be hardened by aging treatment to achieve high strength levels. The material is suitable for cryogenic temperatures down to -320°F (-196°C) and can be used in temperatures up to 2100°F (1149°C) in non-oxidizing atmospheres. It has excellent weldability and can be joined using various welding processes, including gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and electron beam welding (EBW).

| Product Name: 17-4PH Plate |

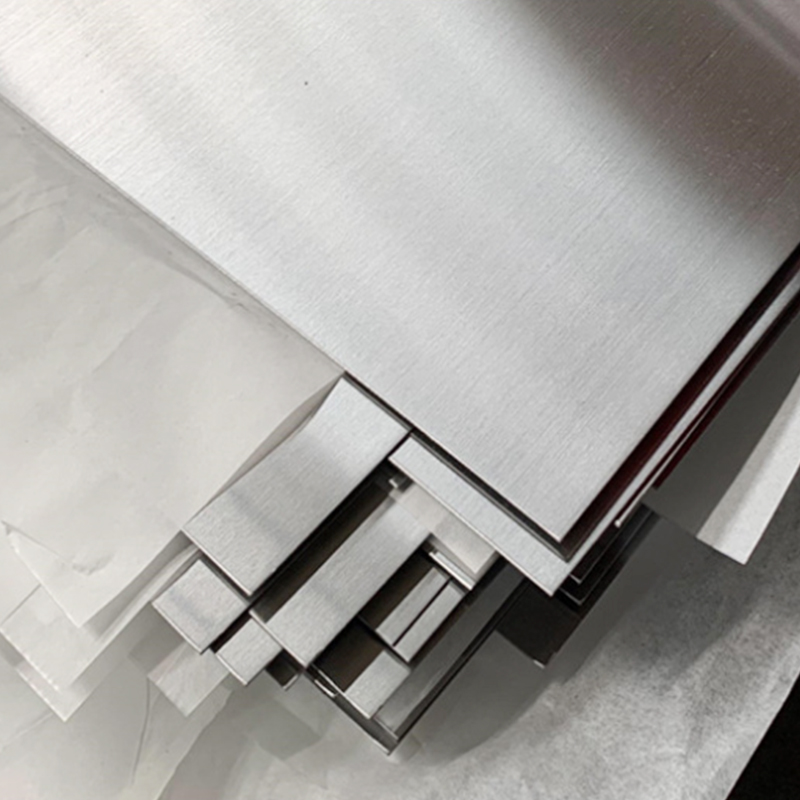

| The material is available in plate, sheet, and bar forms. The thickness of the plate and sheet ranges from 0.031 in. (0.8 mm) to 1.0 in. (25 mm), while the size of the bar ranges from 1/2 in. (12.7 mm) to 8 in. (203 mm). |

| Mechanical properties | Yield Strength: 350 ksi (2,400 MPa) |

| Tensile Strength: 680 ksi (4,700 MPa) | |

| Elongation: 12% | |

| Reduction of Area: 35% | |

| Hardness: 31 HRC (Rockwell C scale) |

| Chemical composition |

| C | Mn | Si | P | S | Cr | Ni | Cu | Mo | Al |

| 0.03 max | 1.00 max | 0.30 max | 0.04 max | 0.01 max | 15.00 -17.50 | 3.00 -5.00 | 3.50 -4.50 | 0.50 max | 0.10 max |