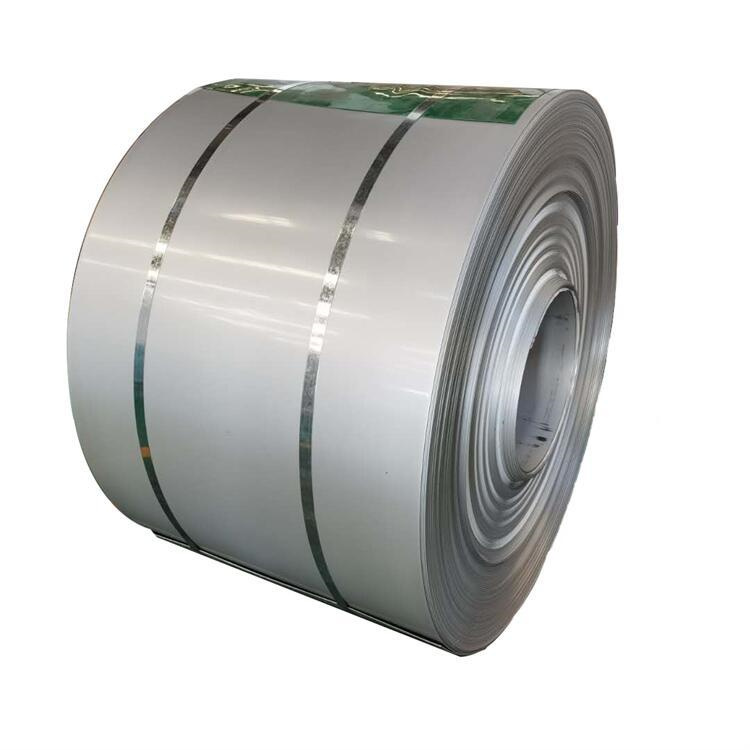

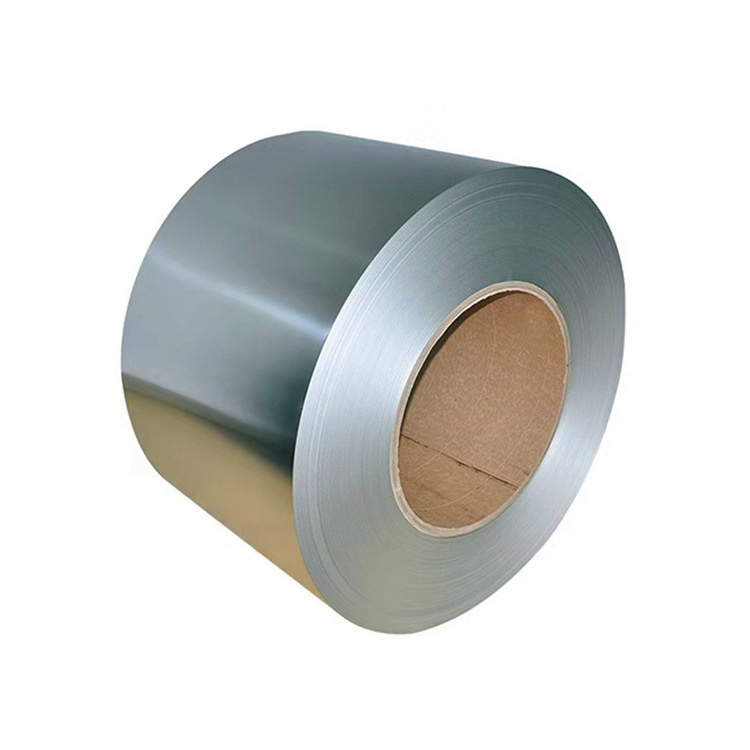

201 Stainless Steel Hot-Rolled Coils

201 Stainless Steel Hot-Rolled Coils is a crucial step in the production of 201 stainless steel, ensuring its desired properties and dimensional accuracy. The process involves heating the steel to a plastic state and then rolling it to achieve the desired shape and thickness. 201 stainless steel, a versatile corrosion-resistant alloy, offers excellent formability, making it an ideal choice for a range of applications.

| Stainless Steel Coil | |

| Standard: | ASTM,GB,JIS,AISI,EN,DIN |

| Grade: | 201/304/316L/310S/254/2205/2507/904L, etc. |

| Width(mm): | 1000/1219/1500/1800/2000mm or Customized |

| Thickness(mm): | Hot Rolled: 3.0mm-10.0mm or Customized |

| Surface: | No.1,No.3,No.4,TR,HL,2D,2B,BA,8K |

| Packing: | Standard Export Pack or Customized |

| Lead Time: | 7~14 days |

201 stainless steel boasts excellent tensile strength, making it suitable for manufacturing components that require ductility and fatigue resistance. Its good corrosion resistance and weldability make it widely used in automotive, architectural, and marine industries. Additionally, its easy machinability makes it a popular choice for fabrication of kitchenware, cutlery, and hardware.

Applications of 201 stainless steel hot rolled coil include but are not limited to:

- Automotive body panels and components

- Marine hardware and fittings

- Chemical processing equipment

- Food processing equipment

- HVAC ductwork

- Architectural cladding and fittings

With its unique combination of properties, 201 stainless steel hot rolled coil offers a cost-effective solution for a variety of applications that require corrosion resistance, durability, and aesthetic appeal.