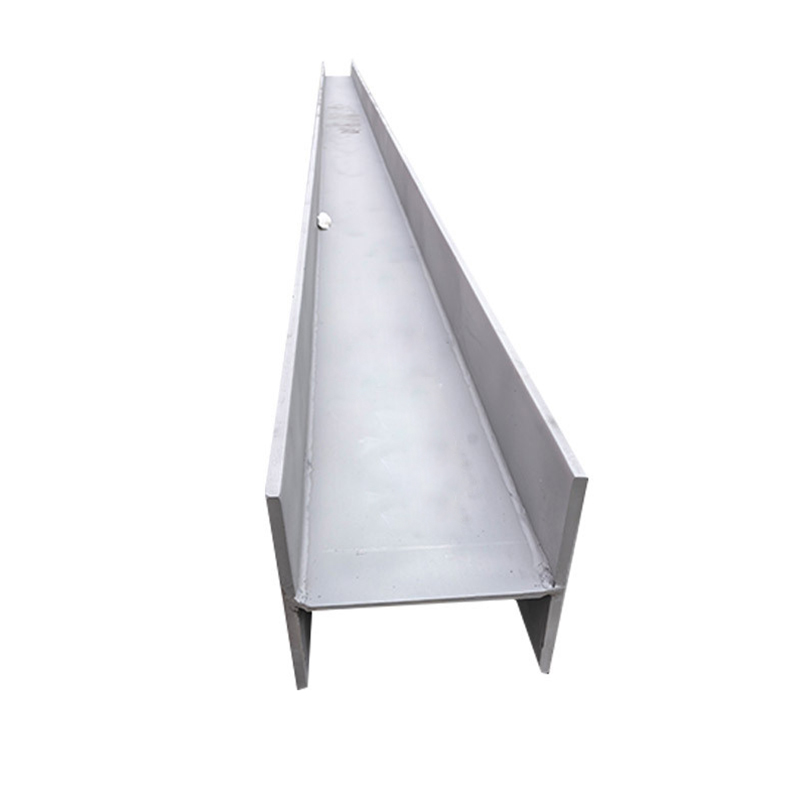

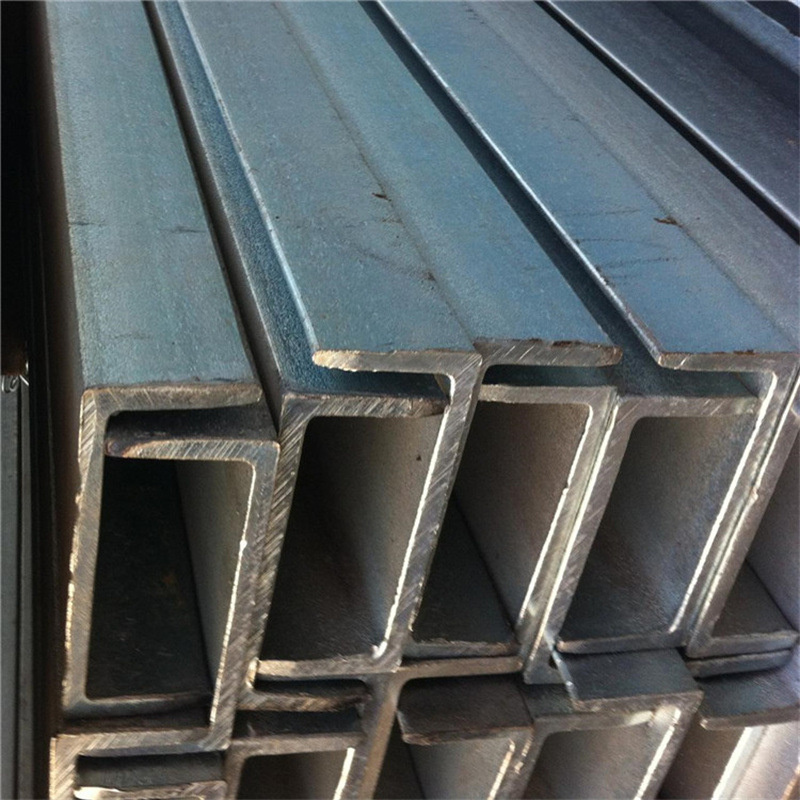

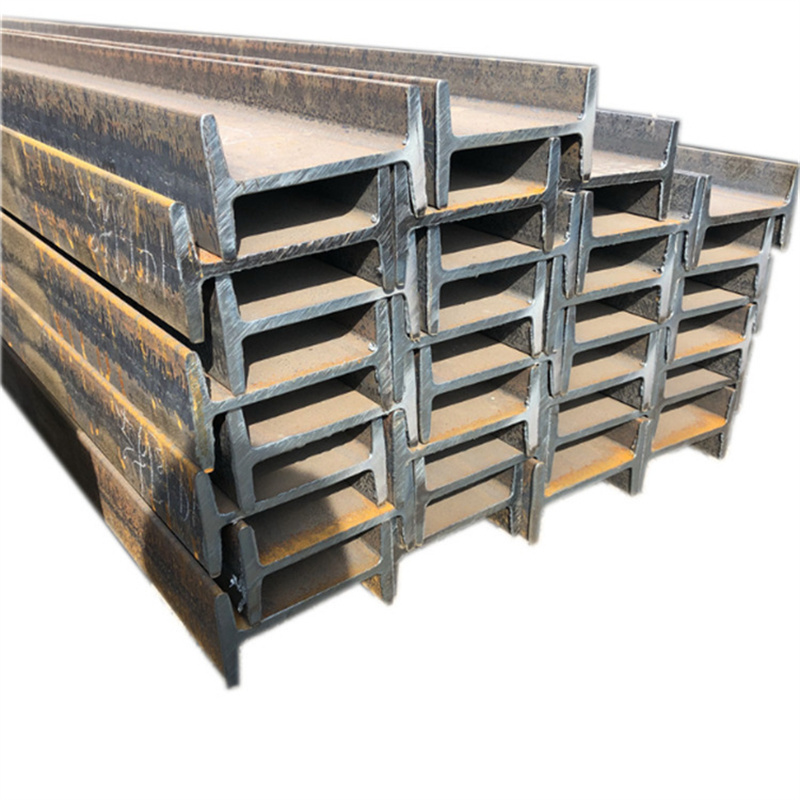

201 stainless steel I-beam

The 201 stainless steel I-beam is a high-quality structural steel that offers exceptional strength and durability. With its unique combination of corrosion resistance and tensile strength, it is an excellent choice for a wide range of applications, including construction, manufacturing, and more.

1.High Strength: The 201 stainless steel used in the I-beam offers superior tensile strength, making it capable of handling heavy loads and resist deformation under pressure.

2.Corrosion Resistance: The 201 stainless steel's inherent corrosion resistance ensures that the I-beam maintains its structural integrity in harsh environments, reducing the need for frequent maintenance and replacement.

3.Durable: The 201 stainless steel I-beam is designed to withstand years of continuous use, making it an ideal choice for long-term projects and applications.

4.Easy to Install: The I-beam is designed with simple installation methods, making it easy to incorporate into various structures and assemblies.

5.Wide Applications: The 201 stainless steel I-beam is suitable for use in a variety of industries and applications, such as construction, bridges, vehicles, and more.

Material: 201 stainless steel

Dimensions: Available in various sizes and shapes to meet specific requirements

Finish: Polished or powder-coated options available

Guarantee: All products are backed by a limited warranty for material and workmanship.

Whether you're looking for a durable steel I-beam for a construction project or seeking a long-lasting solution for a vehicle or other industrial application, the 201 stainless steel I-beam offers an exceptional combination of strength, corrosion resistance, and durability. Contact us today to learn more about our range of 201 stainless steel I-beams and how they can meet your specific needs.

| Product Name | 201 stainless steel I-beam |

| Material composition | Chromium (Cr): 16.00-18.00% Nickel (Ni): 5.50-6.50% Silicon (Si): 1.00% Max Manganese (Mn): 7.50% Max Sulphur (S): 0.05% Max Phosphorus (P): 0.04% Max |

| Other Elements | Carbon (C): 0.15% Max Titanium (Ti): 0.10% Max Aluminum (Al): 0.75% Max Nitrogen (N): 0.20% Max |

| Physical Properties | Melting Point: 1330-1380°C Thermal Conductivity: 16.2 W/m·K at 20°C Specific Heat: 0.46 kJ/(kg·K) at 20°C Thickness: Available in various thicknesses depending on application requirements. Dimensions: Standard I-shape cross-section with specified width and height. |

| Mechanical Properties | Yield Strength: 245 MPa Min Tensile Strength: 520 MPa Min Elongation: 40% Min Impact Strength: As per ASTM A370 standard depending on application requirements. Dimensions: Standard I-shape cross-section with specified width and height. |

| Corrosion Resistance Properties | Austenitic Class: Ferritic/Austenitic (F/A) Passivation: Recommended for long-term corrosion protection. Corrosion Resistance: Good in most environments, but not suitable for high chloride environments. |

| Processing Properties | Weldability: Excellent, with standard welding techniques. Machinability: Fairly easy to machine. |