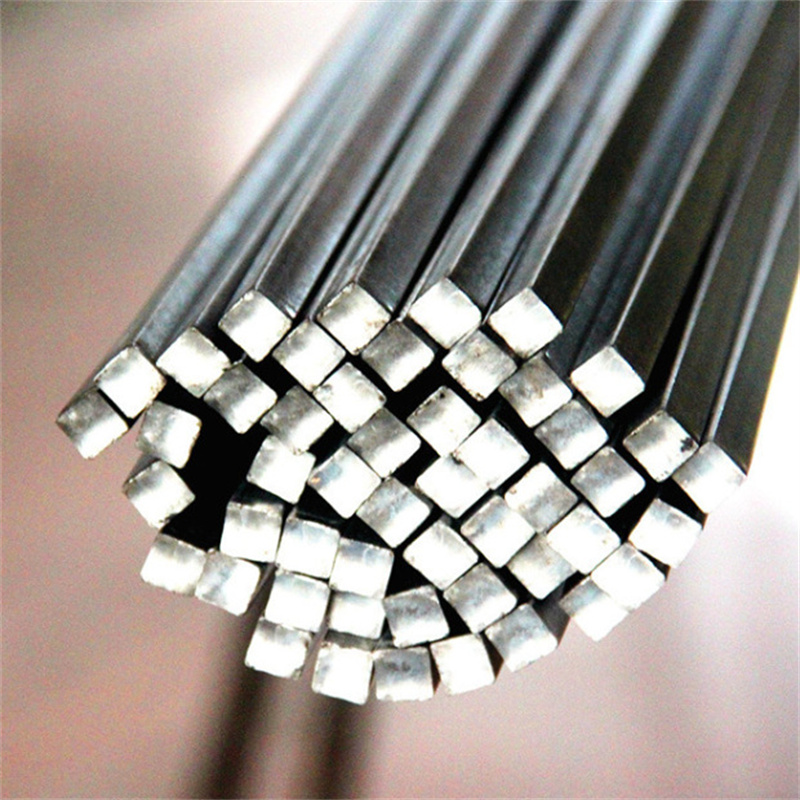

201 stainless steel square steel

Introduction

201 stainless steel square steel is a high-quality building material widely used in various architectural and decorative projects. Due to its excellent corrosion resistance and high strength, 201 stainless steel square steel has become an ideal choice for the construction industry.

Applications

201 stainless steel square steel can be used in various architectural and engineering projects, including exterior and interior wall cladding, ceilings, columns, partitions, furniture, and other structural components. It is also suitable for use in harsh environments, such as coastal areas, industrial facilities, and outdoor spaces.

Advantages

201 stainless steel square steel offers superior corrosion resistance, durability, and strength compared to traditional building materials. It is also easy to clean and maintain, and does not require painting or other surface treatments. In addition, 201 stainless steel square steel has a modern and sleek appearance that complements both traditional and contemporary designs.

Specifications

Available in a variety of sizes and thicknesses to meet different design requirements, 201 stainless steel square steel is available in both straight and bent forms. It can also be cut, bent, and drilled according to customer needs.

Conclusion

201 stainless steel square steel is an excellent choice for both commercial and residential projects. Its corrosion resistance, durability, strength, and sleek appearance make it a top choice for architects, designers, and contractors working on a wide range of projects.

This article mainly introduces the English parameter table of 201 stainless steel square steel, including its chemical composition, mechanical properties, physical properties and other parameters.

| Chemical composition | C: ≤0.15 Si: ≤1.0 Mn: ≤2.0 P: ≤0.5 S: ≥0.030 Ni: 0.6-1.2 Cr: 16.0-18.0 Mo: ≤0.6 |

| Mechanical properties | Tensile strength (Rm) ≥310 N/mm2 Yield strength (Rp0.2) ≥190 N/mm2 Elongation (A) ≥40% Hardness HB ≤187 HRB ≤90 HV ≤200 |

| Physical properties | Density (ρ) 7.93 g/cm3 Specific heat capacity (c) 0.5 J/(g·℃) Thermal conductivity (λ) 16.3 W/(m·℃) Elastic modulus (E) 194 GPa Poisson's ratio (ν) 0.341 Resistance Rate (Ω) 78 × 10-6 Ω·m Thermal expansion coefficient (α) 1.4 × 10-5 ℃-1 Magnetic and non-magnetic melting point range 1300~1400 ℃ Processing temperature hot rolling 900~1100 ℃; cold rolling 600& #126;900℃. |