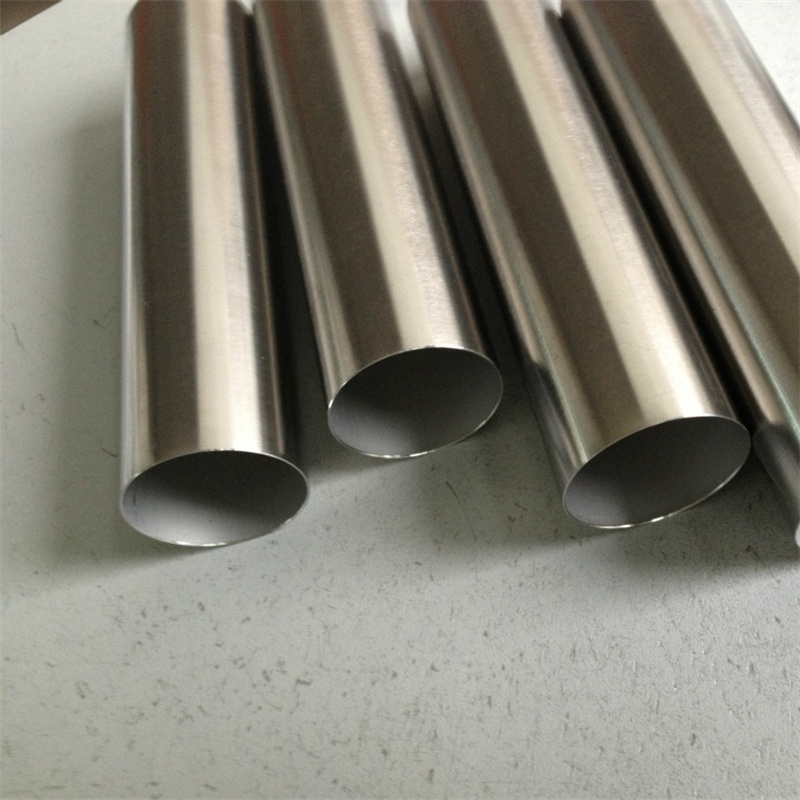

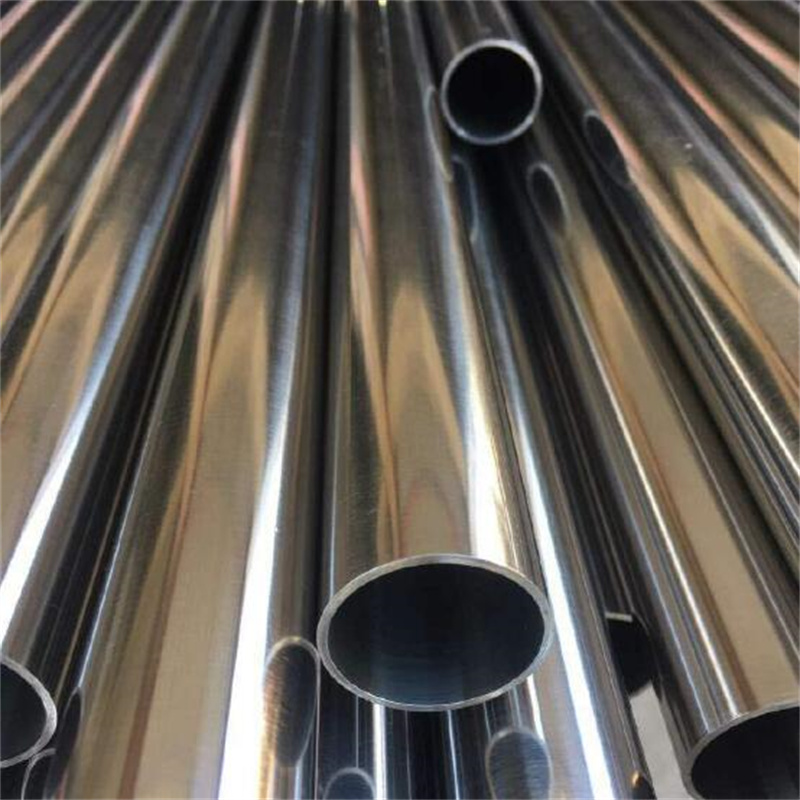

2205 Precision Tube

The 2205 precision tube is a high-quality stainless steel tube that offers exceptional corrosion resistance and mechanical properties. This tube is made from duplex stainless steel, which contains a balanced combination of austenite and ferrite phases. It exhibits excellent strength and toughness, making it suitable for various applications in demanding environments.

Corrosion Resistance: The 2205 precision tube is highly resistant to various corrosive environments, including chlorides, acids, and pitting corrosion. It outperforms conventional stainless steel tubes like 304 and 316 in terms of corrosion resistance.

High Strength: Due to its duplex microstructure, the 2205 precision tube possesses superior mechanical properties compared to austenitic stainless steels. It offers higher yield strength, ultimate tensile strength, and impact toughness, making it ideal for structural applications.

Good Weldability: This precision tube can be easily welded using common welding techniques such as gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and shielded metal arc welding (SMAW). It maintains its mechanical and corrosion-resistant properties after welding.

Wide Range of Applications: The 2205 precision tube finds applications in industries such as chemical processing, oil and gas, pulp and paper, marine, and food processing. It is suitable for heat exchangers, pressure vessels, piping systems, and various structural components in aggressive environments.

Please note that the specific parameters for 2205 precision tubes may vary depending on manufacturer and customer specifications. It is advisable to consult with the supplier or refer to the relevant standards for precise technical details.

| Material | Duplex Stainless Steel (2205) |

| Outer Diameter | Customizable according to application requirements |

| Wall Thickness | Various options available |

| Length | Customizable |

| Standards | ASTM A789, ASTM A790, etc. |

| Corrosion Resistance | Excellent resistance to chlorides, acids, and pitting corrosion |

| Strength Properties | Yield Strength: Typically above 450 MPa (65 ksi) Ultimate Tensile Strength: Typically between 620-800 MPa (90-116 ksi) Impact Toughness: Good toughness at both room temperature and low temperatures Weldability: Can be easily welded using common techniques such as GTAW, GMAW, and SMAW |

| Applications | Chemical processing, oil and gas, pulp and paper, marine, food processing, heat exchangers, pressure vessels, piping systems, structural components in aggressive environments |