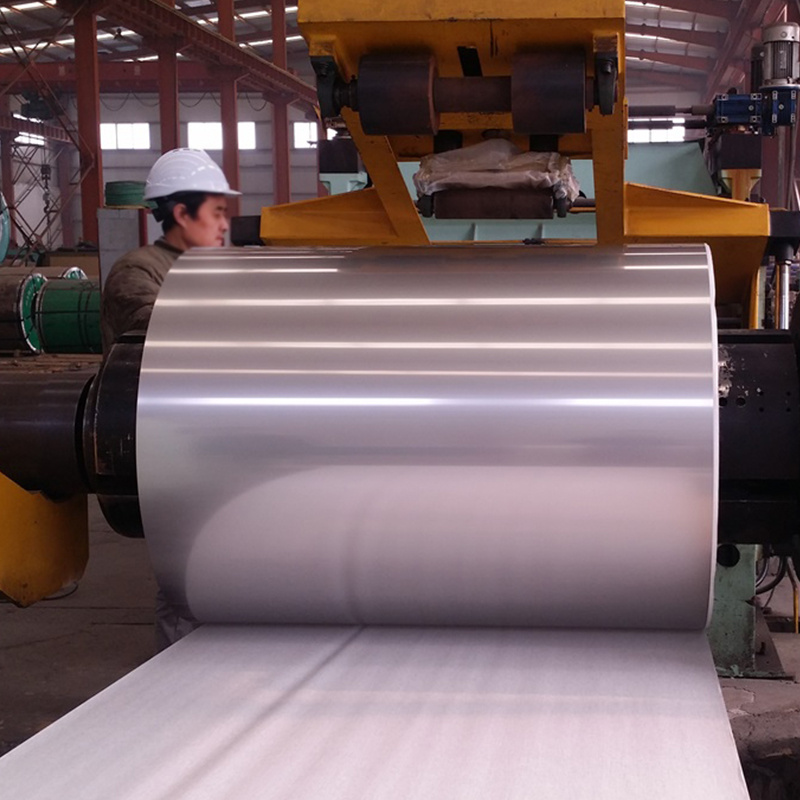

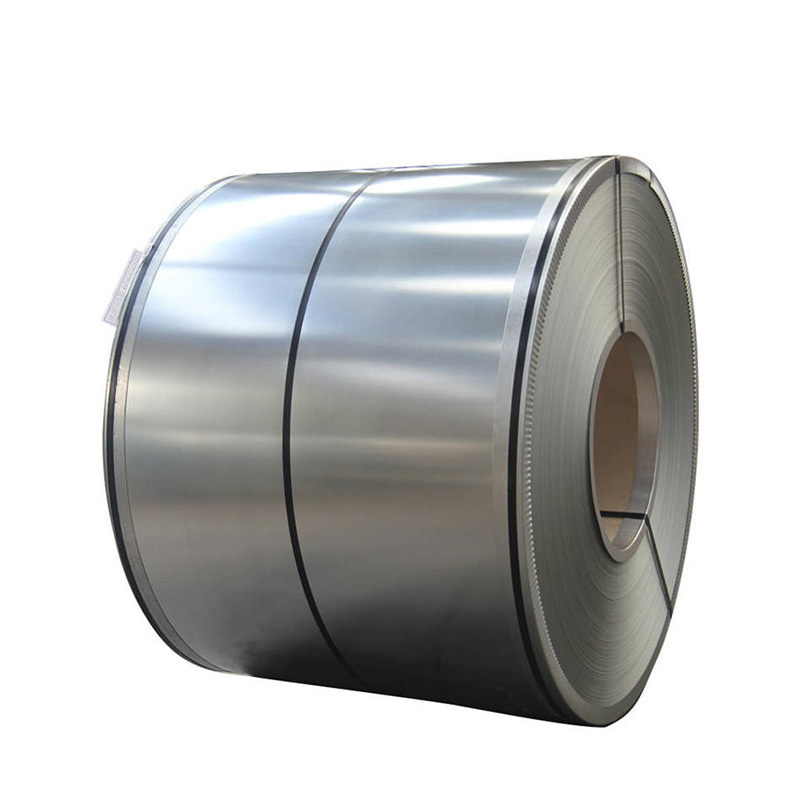

2205 Stainless Steel Cold-Rolled Coils

2205 stainless steel, a versatile material, finds applications across various industries. As the name suggests, the cold rolled coil is produced through a series of cold rolling processes, resulting in a material with excellent formability and mechanical properties.

| Stainless Steel Coil | |

| Standard: | ASTM,GB,JIS,AISI,EN,DIN |

| Grade: | 201/304/316L/310S/254/2205/2507/904L, etc. |

| Width(mm): | 1000/1219/1500/1800/2000mm or Customized |

| Thickness(mm): | Cold Rolled: 0.15mm-3.0mm |

| Surface: | No.1,No.3,No.4,TR,HL,2D,2B,BA,8K |

| Packing: | Standard Export Pack or Customized |

| Lead Time: | 7~14 days |

During the cold rolling process, the steel undergoes multiple passes of reduction in thickness under controlled conditions, ensuring consistent quality and dimensional accuracy. The process not only enhances the material's strength but also improves its corrosion resistance.

2205 stainless steel offers a unique combination of properties, making it an ideal choice for various applications. It possesses high strength, good formability, and excellent corrosion resistance, even in severe environments. Additionally, its unique microstructure provides improved resistance to stress corrosion cracking.

One of the key applications of 2205 stainless steel cold rolled coil is in the oil and gas industry. Its corrosion resistance and strength make it suitable for use in pipelines, offshore structures, and other critical components exposed to harsh environments. Furthermore, it is widely used in the production of automobiles, where its strength and durability are highly valued.

Overall, 2205 stainless steel cold rolled coil offers an excellent balance of properties, making it a material of choice for various demanding applications. Its adaptability and reliability ensure its longevity and make it a cost-effective solution for a range of industrial applications.