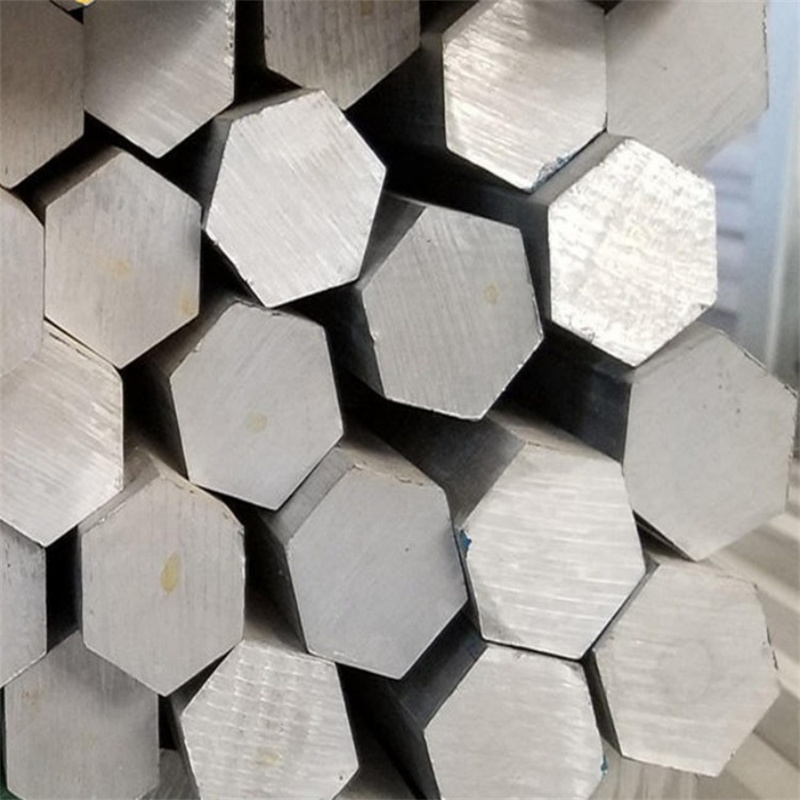

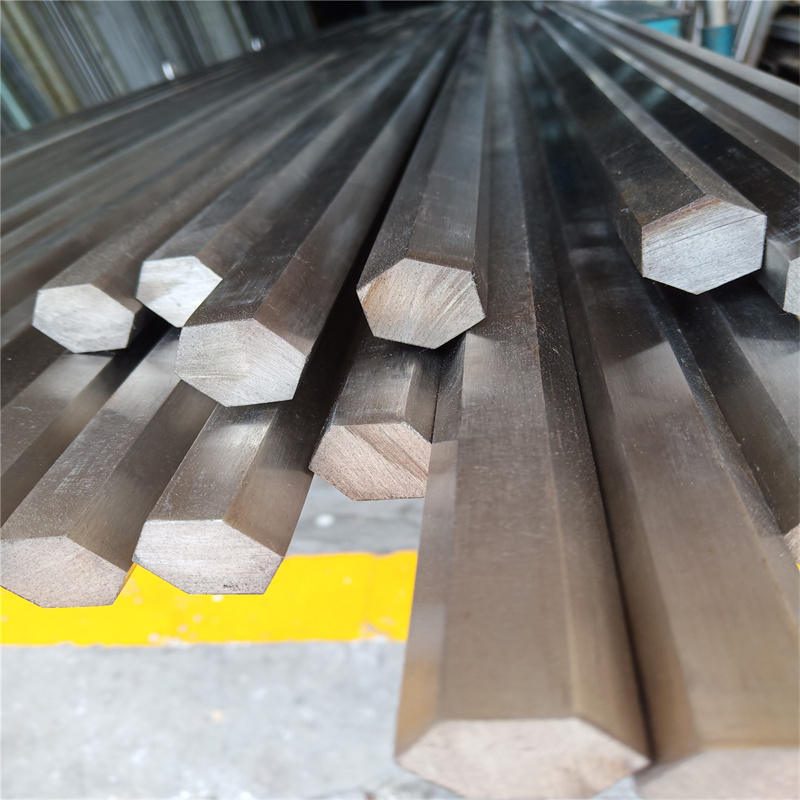

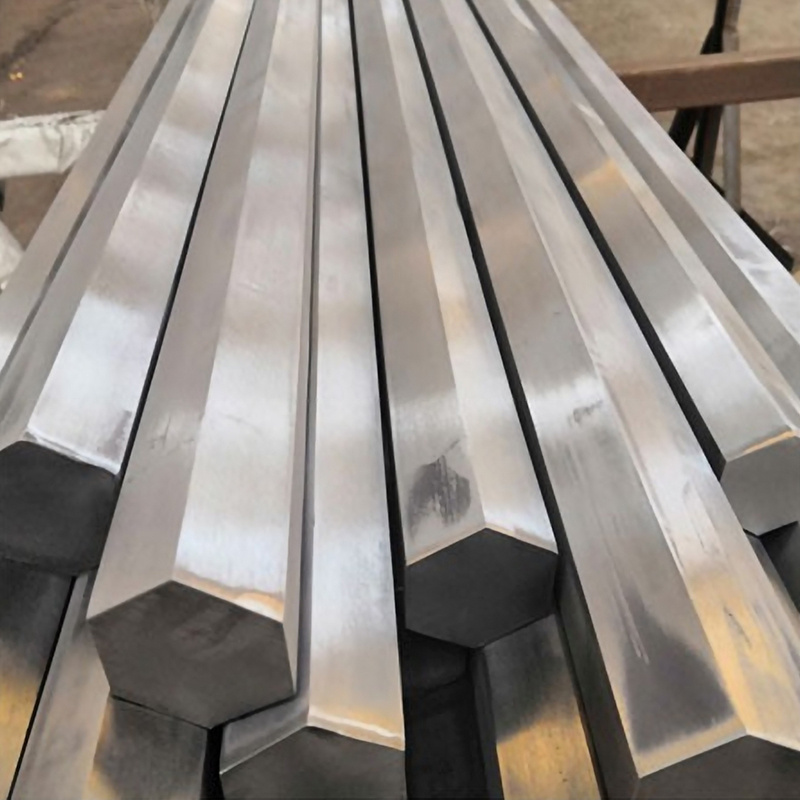

2205 stainless steel hexagonal steel

The 2205 stainless steel hexagon bar is a high-performance material, combining the best attributes of stainless steel and duplex steel. This exceptional grade of steel offers exceptional strength, corrosion resistance, and durability, making it an excellent choice for a wide range of applications.

The 2205 stainless steel hexagon bar offers the following properties:

Exceptional strength: The 2205 grade features a high tensile strength, providing excellent performance in high-stress applications.

Corrosion resistance: The duplex steel composition offers superior resistance to corrosion, making it suitable for use in harsh environments.

Durability: The 2205 grade offers excellent durability, ensuring longevity in even the most demanding applications.

Versatility: The 2205 stainless steel hexagon bar can be used for a variety of applications, including structural components, piping systems, and more.

The 2205 stainless steel hexagon bar is well-suited for a range of applications, including:

Construction: The high strength and durability of the 2205 grade make it an excellent choice for use in construction projects, such as beams, columns, and bracing.

Piping systems: The corrosion resistance and durability of the 2205 grade make it suitable for use in piping systems, including water treatment facilities and chemical processing plants.

Machinery and equipment: The versatility of the 2205 grade makes it an excellent choice for use in machinery and equipment manufacturing, including pumps, valves, and other industrial components.

In conclusion, the 2205 stainless steel hexagon bar is an exceptional grade of steel, offering a unique combination of strength, corrosion resistance, and durability. Its wide range of applications makes it an excellent choice for a variety of projects, whether for structural components, piping systems, or machinery and equipment manufacturing. With its exceptional performance and longevity, the 2205 stainless steel hexagon bar is sure to be a valuable addition to your next project.

| Material | 2205 Duplex Stainless Steel |

| Chemical Composition | Carbon (C): ≤ 0.03% Manganese (Mn): ≤ 2.00% Silicon (Si): ≤ 1.00% Phosphorus (P): ≤ 0.04% Sulfur (S): ≤ 0.03% Chromium (Cr): 1.4-3.0% Nickel (Ni): 0.8-2.5% Molybdenum (Mo): 0.4-3.5% Nitrogen (N): ≤ 0.20% |

| Physical Properties | Thermal conductivity: 16 W/m·K Electrical resistivity: 100 microhm·in Specific heat capacity: 480 J/(kg·K) Thermal expansion coefficient: 11.5 x 10^-6/K Young's modulus: 210 GPa Poisson's ratio: 0.33 |

| Mechanical Properties | Tensile strength: ≥ 630 MPa Yield strength: ≥ 450 MPa Elongation: ≥ 25% Impact toughness: ≥ 45 J/cm² (at -25°C) Fatigue limit: ≥ 270 MPa Brinell hardness: ≥ 217 HB |

| Corrosion resistance properties | Sulfide stress corrosion resistance: ≥ Grade C (ASTM G48) Intergranular corrosion resistance: ≥ Grade C (ASTM G48) General corrosion resistance: Excellen |

| Processing Properties | Machinability: Good Weldability: Good (requires preheat and postheat treatment) |

316 and 316L stainless steel hot rolled plates are widely used in various industries due to their excellent corrosion resistance, high temperature strength, and exceptional mechanical properties. These plates are produced through a hot rolling process, where the steel is heated above its recrystallization temperature and then passed through a series of rollers to achieve the desired thickness.

Corrosion Resistance: Both 316 and 316L stainless steel exhibit excellent resistance to a wide range of corrosive environments, including acidic and chloride-containing solutions.

High Temperature Strength: These grades maintain their strength and integrity at elevated temperatures, making them suitable for applications involving heat or thermal cycling.

Mechanical Properties: 316 and 316L offer good tensile and yield strength, as well as excellent toughness, enabling them to withstand heavy loads and impacts.

Weldability: These stainless steels can be easily welded, allowing for the fabrication of complex structures and components.

Suitable for Food and Medical Industries: Due to their non-reactive nature, 316 and 316L are commonly used in food processing, pharmaceutical, and medical equipment where hygiene and compatibility are critical.

Chemical processing equipment

Heat exchangers

Pharmaceutical and medical equipment

Food and beverage industry machinery

Marine environments (boats, shipbuilding)

Oil and gas processing equipment

Pulp and paper industry machinery

Please note that this is a general product introduction, and specific technical specifications may vary depending on the manufacturer or supplier.