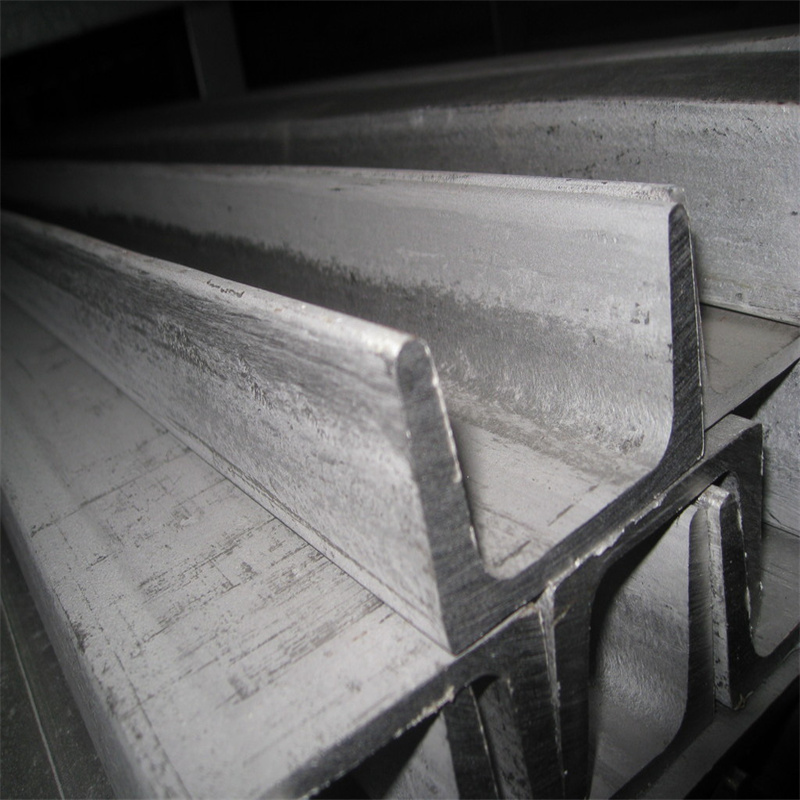

2507 stainless steel channel

The 2507 stainless steel channel steel is a high-performance corrosion-resistant material, widely used in various industries such as chemical processing, oil and gas exploration, marine engineering, and more. It offers excellent resistance to acids, alkalis, and other corrosive substances, making it an ideal choice for extreme environments where regular steel would quickly corrode.

High Corrosion Resistance: 2507 stainless steel has a significantly higher corrosion resistance than other stainless steels. It contains a higher amount of chromium and molybdenum, which provide excellent resistance to acids and alkalis.

High Strength: The 2507 stainless steel channel steel has a high tensile strength and yield strength, making it suitable for use in structural applications where high loads and stress are present.

Good Weldability: The 2507 stainless steel can be easily welded using standard welding techniques, ensuring easy fabrication and repairs.

High Temperature Resistance: The 2507 stainless steel has good high-temperature properties, making it suitable for use in high-temperature applications.

Conclusion:The 2507 stainless steel channel steel is a high-performance material that offers excellent corrosion resistance, strength, weldability, and high-temperature resistance. Its wide range of applications makes it a versatile choice for various industries where corrosion resistance and durability are essential.

The 2507 stainless steel channel steel is widely used in various industries such as chemical processing plants, oil and gas pipelines, offshore platforms, mining equipment, pulp and paper processing plants, and more. It is also suitable for use in architectural structures, bridges, and other infrastructure projects where longevity and durability are essential.

254 stainless steel channel steel is a high-quality stainless steel material. Its English composition parameter list is as follows:

| Ingredients | Carbon (C): 0.03 max Manganese (Mn): 2.00 max Silicon (Si): 0.50 max Sulfur (S): 0.02 max Phosphorus (P): 0.045 max Chromium (Cr): 23.50-26.50 Molybdenum (Mo): 3.00-5.00 Nickel (Ni): 6.00-8.00 Nitrogen (N): 0.24-0.32 |

| Properties | Hardness: Brinell hardness ≥ 217HB Yield Strength: ≥ 620 MPa Tensile Strength: ≥ 835 MPa Elongation: ≥ 35% Impact Resistance: ≥ 117 J (Charpy impact test at -40℃) Corrosion Resistance: Excellent resistance to corrosion in most environments, including chloride-containing environments. |

| Applications | Architecture: Structural components in building and construction, including roofing, ceilings, and partitions. Industrial Equipment: Support structures, frames, and other components in manufacturing, processing, and other industrial operations. Transportation: Components in vehicles, ships, and other transportation equipment. Utilities: Support structures for power lines, pipelines, and other utility infrastructure. |