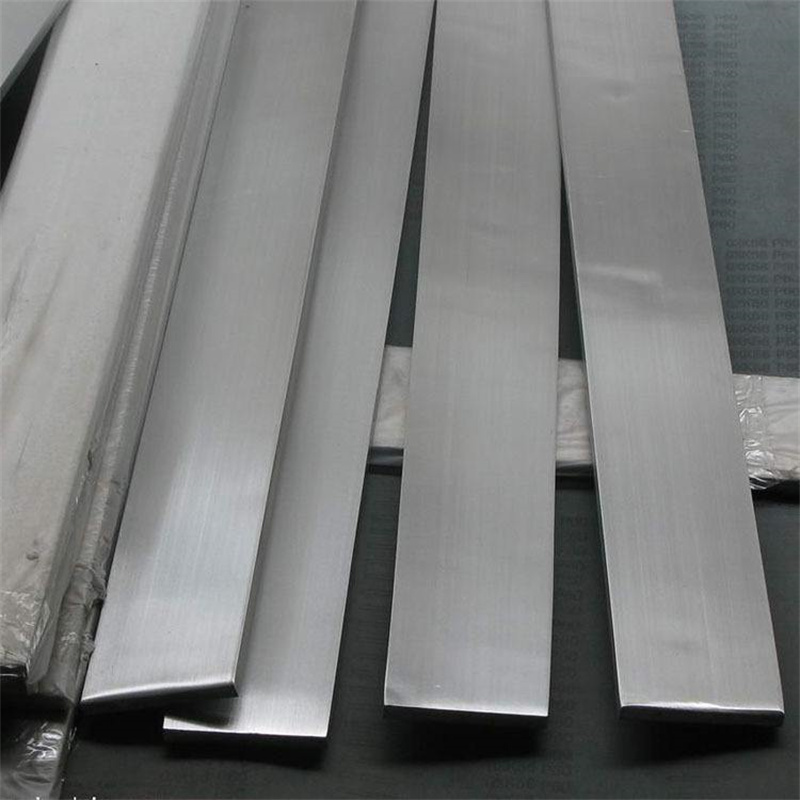

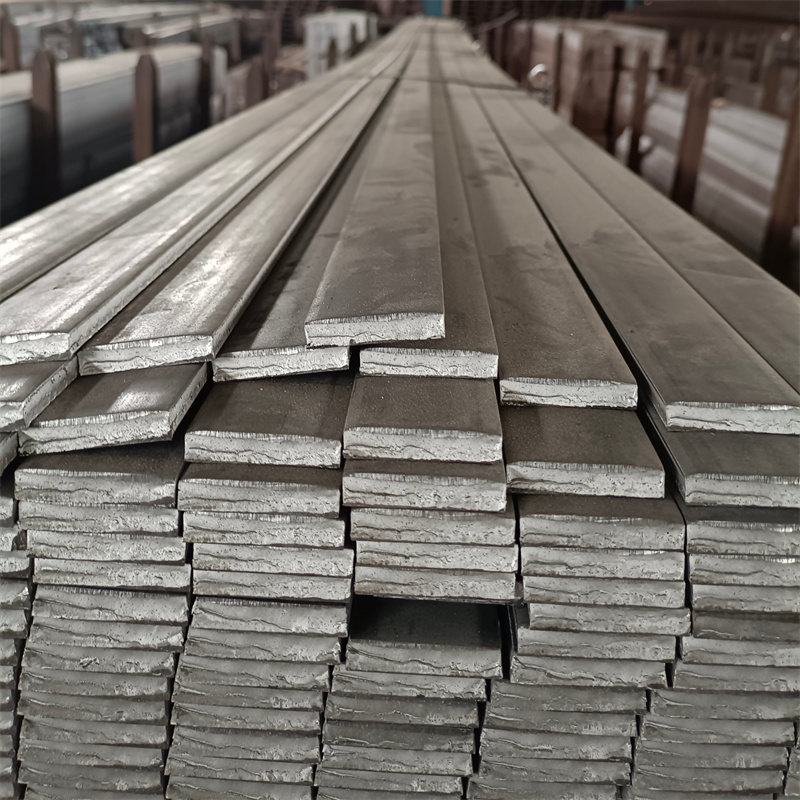

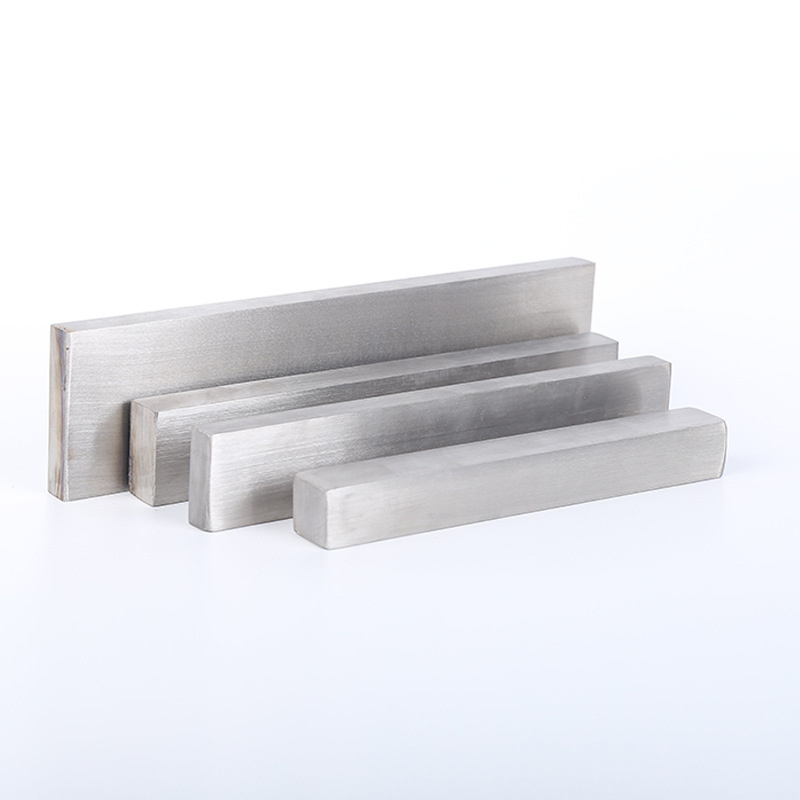

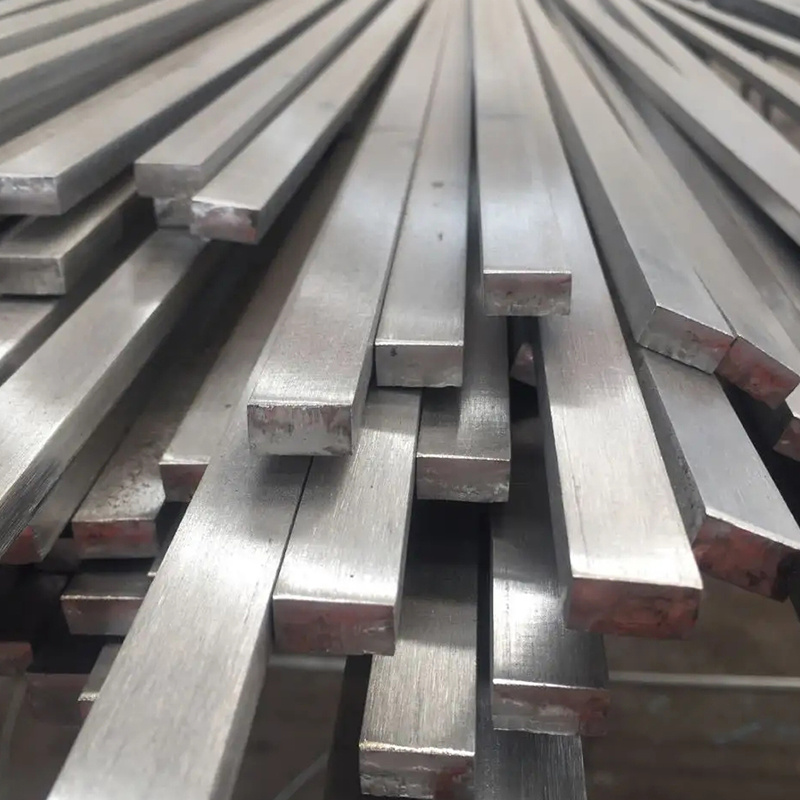

2507 stainless steel flat steel

The 2507 stainless steel flat bar is a high-performance alloy, renowned for its exceptional corrosion resistance and exceptional strength. It offers superior tensile strength, yield strength, and impact resistance, making it an excellent choice for a wide range of applications.

Origin and Development:Developed in the early 21st century, 2507 stainless steel is a new generation of duplex stainless steel, which combines the advantages of both austenitic and ferritic stainless steel. It has excellent weldability, forming, and fabricating properties, making it suitable for a variety of applications in the chemical, petroleum, energy, and other industries.

Composition and Properties:2507 stainless steel has a chemical composition that includes chromium, nickel, molybdenum, nitrogen, and copper. It offers good corrosion resistance in acids, alkalis, and other corrosive environments. It also has good toughness at low temperatures and good stress corrosion resistance. In addition, 2507 stainless steel has excellent mechanical properties, such as high tensile strength and yield strength, as well as good impact resistance.

Applications:Due to its exceptional corrosion resistance and mechanical properties, 2507 stainless steel flat bar is widely used in various industries. It can be used in the production of chemical equipment, petroleum pipelines, offshore platforms, energy plants, shipbuilding, and other fields that require high corrosion resistance and strength. It is also suitable for use in automobiles, aircraft, and other transportation equipment that require high corrosion resistance and mechanical properties.

Production Process:The production process of 2507 stainless steel flat bar includes melting, casting, rolling, heat treatment, and cutting. The melting process adopts high-purity raw materials to ensure the chemical composition and microstructure of the steel. The casting process uses appropriate molds to form the steel into the desired shape. The rolling process reduces the thickness of the steel plate and improves its surface quality. The heat treatment process controls the microstructure of the steel to achieve the desired mechanical properties. The cutting process cuts the steel into the required length and specification.

Conclusion:In conclusion, the 2507 stainless steel flat bar is a high-performance alloy that offers exceptional corrosion resistance, mechanical properties, and weldability. It has a wide range of applications in various industries and is an excellent choice for use in corrosive environments that require high strength and durability.

| Product Name | 2205 Stainless Steel Flat Bar |

| Chemical Composition | Element content (%) C (carbon) ≤0.030 Mn (manganese) ≤2.00 P (phosphorus) ≤0.035 S (sulfur) ≤0.020 Si (silicon) ≤0.50 Cr (chromium) 24.00-26.00 Ni (Nickel) 6.00-8.00 Mo (molybdenum) 3.00-5.00 N (nitrogen) 0.24-0.32 Cu (copper) ≤0.50 Al (aluminum) ≤0.20 Ti (titanium) ≤0.20 W (tungsten) ≤1.00 Co (cobalt) ≤1.00 V (vanadium) ≤0.10 B (boron) ≤0.01 |

| Chemical Composition | Item Parameter Test Standard (ASTM) Tensile Strength ≥784 MPa ASTM A370, Method B Yield Strength ≥690 MPa ASTM A370, Method B Elongation (Elongation) ≥15% ASTM A370, Method B Hardness (Hardness) ≤223 HB ASTM A370, Method D7663 Impact Toughness ≥15 J/cm2 (7/16 in2) at -40℃ ASTM A370, Method G91-89a, Procedure D6838-89a |