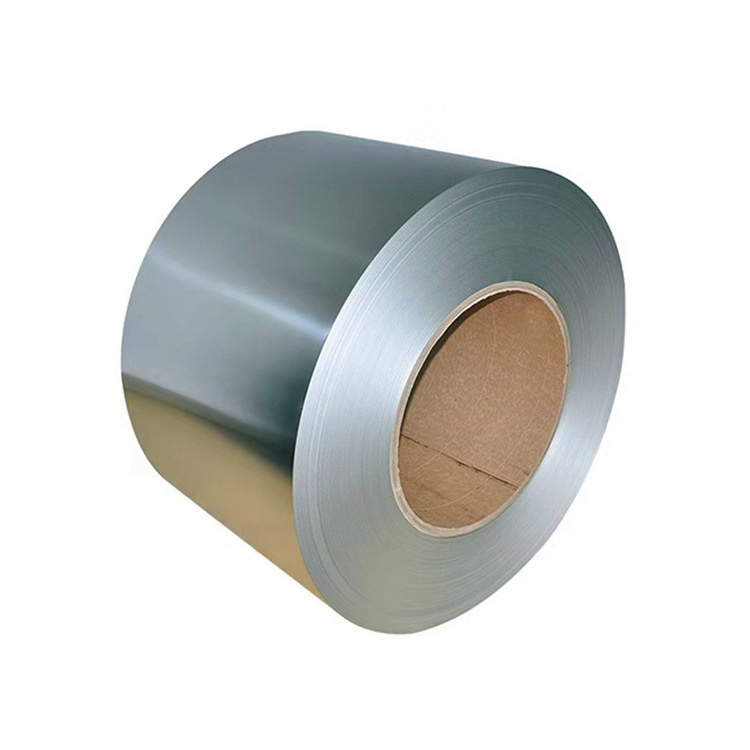

2507 Stainless Steel Hot-Rolled Coils

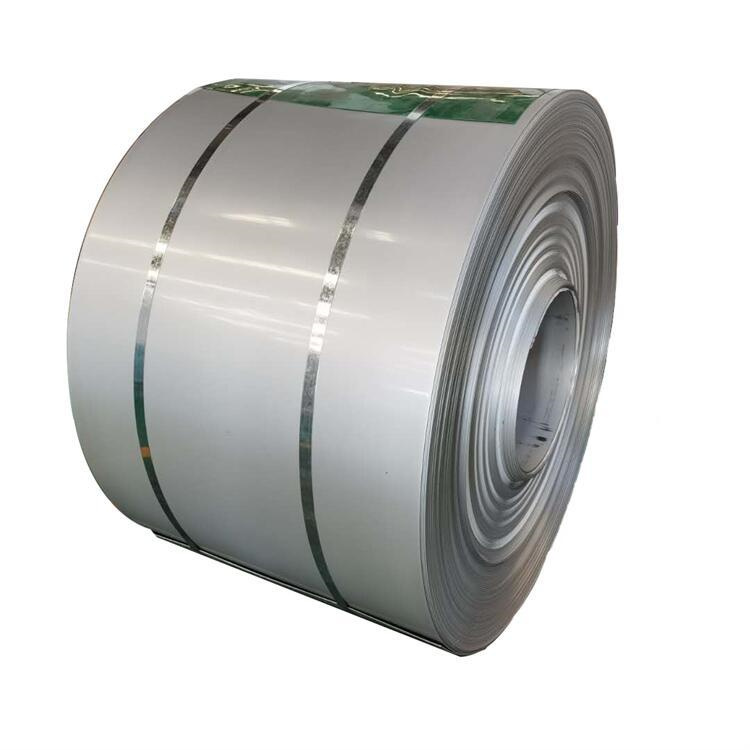

2507 super duplex stainless steel hot rolled coil is a high-performance material, which is widely used in corrosive environments. It is produced by hot rolling process, which involves heating the steel to a plastic state and then rolling it into a coil. The hot rolling process allows for the production of high-quality steel with excellent mechanical properties.

| Stainless Steel Coil | |

| Standard: | ASTM,GB,JIS,AISI,EN,DIN |

| Grade: | 201/304/316L/310S/254/2205/2507/904L, etc. |

| Width(mm): | 1000/1219/1500/1800/2000mm or Customized |

| Thickness(mm): | Hot Rolled: 3.0mm-10.0mm or Customized |

| Surface: | No.1,No.3,No.4,TR,HL,2D,2B,BA,8K |

| Packing: | Standard Export Pack or Customized |

| Lead Time: | 7~14 days |

2507 stainless steel is a super duplex alloy, which means it has excellent resistance to corrosion and high strength. It offers good weldability and can be used in a wide range of applications, including chemical processing, oil and gas production, and marine environments.

The applications of 2507 stainless steel hot rolled coil are diverse. It can be used for the construction of bridges, offshore platforms, and other structures that require high durability and corrosion resistance. It can also be used in the production of equipment that is exposed to corrosive substances, such as tanks and pipelines.

Overall, 2507 super duplex stainless steel hot rolled coil is a high-quality material that offers excellent corrosion resistance and mechanical properties. It is suitable for a wide range of applications and can be used in various industries to enhance the durability and performance of structures and equipment.