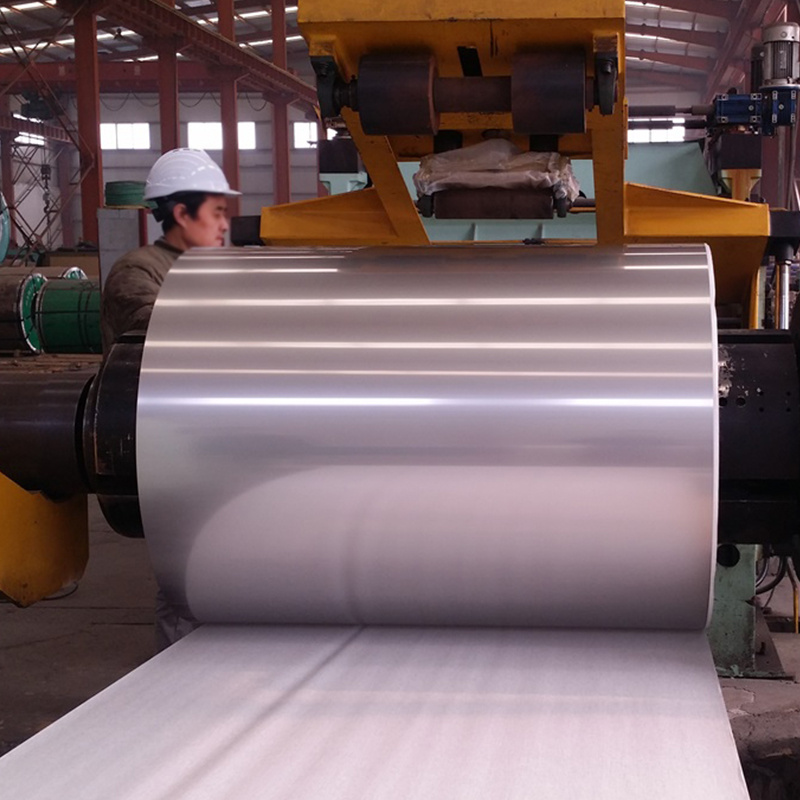

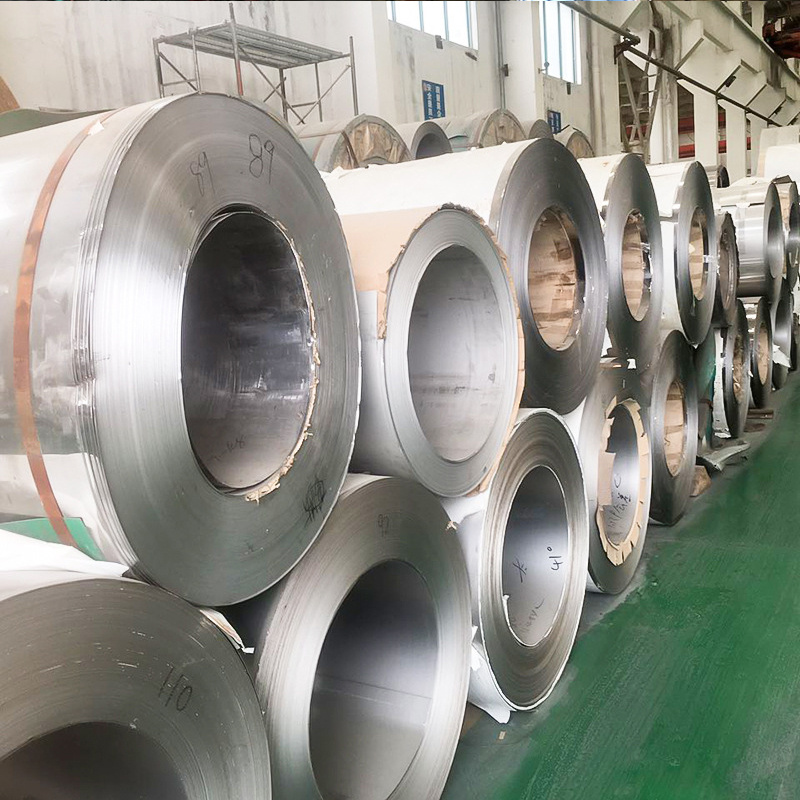

254 Stainless Steel Cold-Rolled Coils

254 stainless steel, a grade renowned for its corrosion resistance, is widely used in a range of industries due to its unique combination of properties. This grade of stainless steel, when processed into cold-rolled coil, offers exceptional formability, making it suitable for a variety of applications.

| Stainless Steel Coil | |

| Standard: | ASTM,GB,JIS,AISI,EN,DIN |

| Grade: | 201/304/316L/310S/254/2205/2507/904L, etc. |

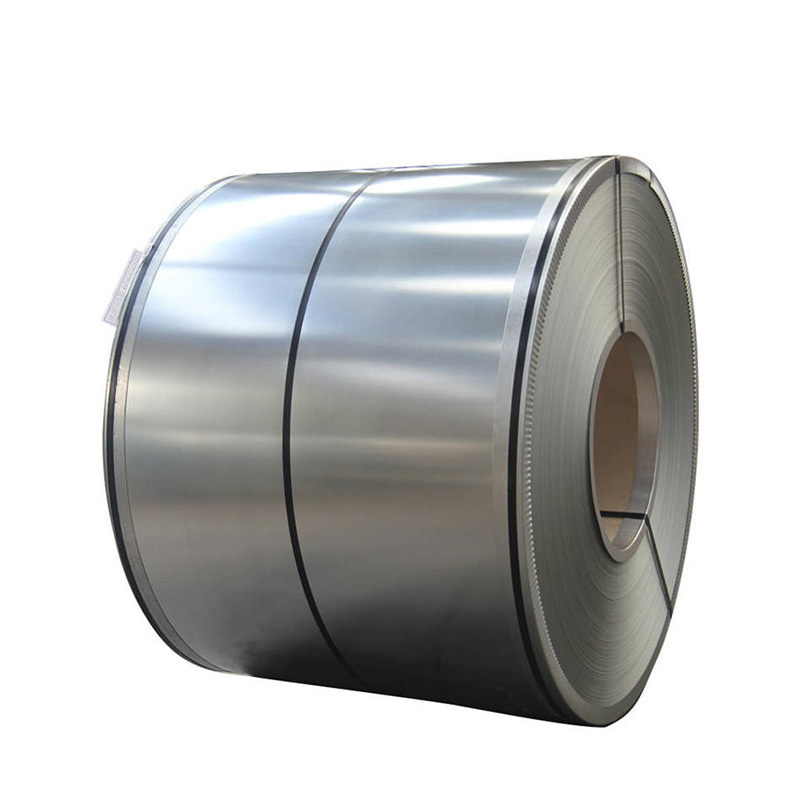

| Width(mm): | 1000/1219/1500/1800/2000mm or Customized |

| Thickness(mm): | Cold Rolled: 0.15mm-3.0mm |

| Surface: | No.1,No.3,No.4,TR,HL,2D,2B,BA,8K |

| Packing: | Standard Export Pack or Customized |

| Lead Time: | 7~14 days |

The production of 254 stainless steel cold-rolled coil involves a series of meticulous processes. The steel is first heated to a malleable state, ensuring even flow during rolling. It is then passed through rolls with decreasing diameters, compressing it to reduce thickness while also aligning the microstructure. The controlled cooling that follows solidifies the steel, locking in its properties.

254 stainless steel's primary attribute is its exceptional corrosion resistance. It offers better chloride stress corrosion resistance than other grades, making it an ideal choice for components exposed to chloride-containing environments. Its good formability and weldability further enhance its versatility.

Applications of 254 stainless steel cold-rolled coil are diverse. It is commonly used in the production of automotive components, chemical processing equipment, food handling equipment, and medical devices due to its resistance to corrosion and ability to withstand rigorous demands.

In conclusion, 254 stainless steel cold-rolled coil offers exceptional performance in a range of applications, making it a material of choice for designers and engineers seeking longevity and reliability in their products.