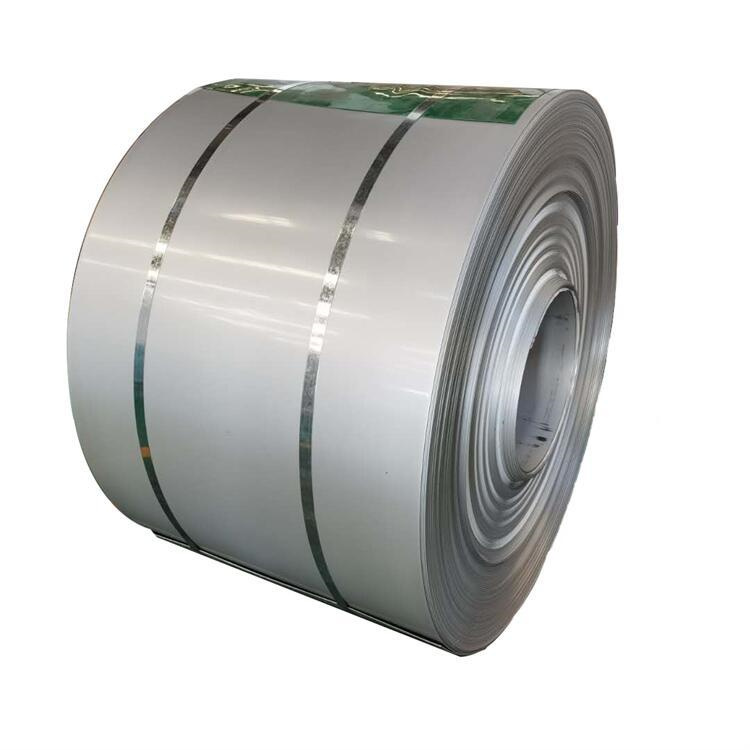

254 Stainless Steel Hot-Rolled Coils

254 Stainless Steel Hot-Rolled Coils, a member of the austenitic family, is a highly corrosion-resistant material, making it an excellent choice for a wide range of applications. This grade of stainless steel offers excellent formability, weldability, and mechanical properties, making it suitable for both indoor and outdoor applications.

| Stainless Steel Coil | |

| Standard: | ASTM,GB,JIS,AISI,EN,DIN |

| Grade: | 201/304/316L/310S/254/2205/2507/904L, etc. |

| Width(mm): | 1000/1219/1500/1800/2000mm or Customized |

| Thickness(mm): | Hot Rolled: 3.0mm-10.0mm or Customized |

| Surface: | No.1,No.3,No.4,TR,HL,2D,2B,BA,8K |

| Packing: | Standard Export Pack or Customized |

| Lead Time: | 7~14 days |

The production of 254 stainless steel hot-rolled coil involves several processes. The first step is the melting of the raw materials, followed by the casting of the molten steel into slabs. These slabs are then reheated and rolled to the desired thickness and width using a hot rolling process. Finally, the coil is annealed to improve its mechanical properties before being cut to length and coiled for shipment.

254 stainless steel offers a combination of excellent corrosion resistance, strength, and ductility. It has good formability, making it easy to bend, flatten, and stamp. Additionally, 254 stainless steel has excellent weldability and can be joined using a variety of welding processes. It also has good resistance to most acids and alkalis, making it suitable for use in chemical processing and other corrosive environments.

Due to its corrosion resistance and mechanical properties, 254 stainless steel hot-rolled coil is used in a variety of applications. It is commonly used in the construction industry for building exteriors, interior fixtures, and architectural components. It is also used in the food processing industry for equipment and utensils that require sanitary conditions. Other applications include automotive components, marine hardware, and piping systems.