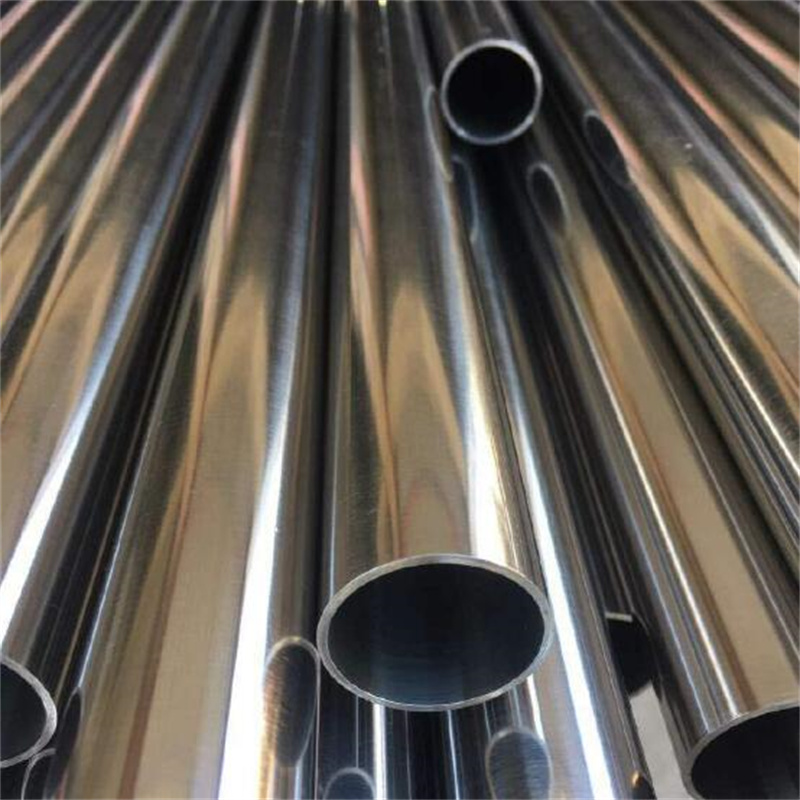

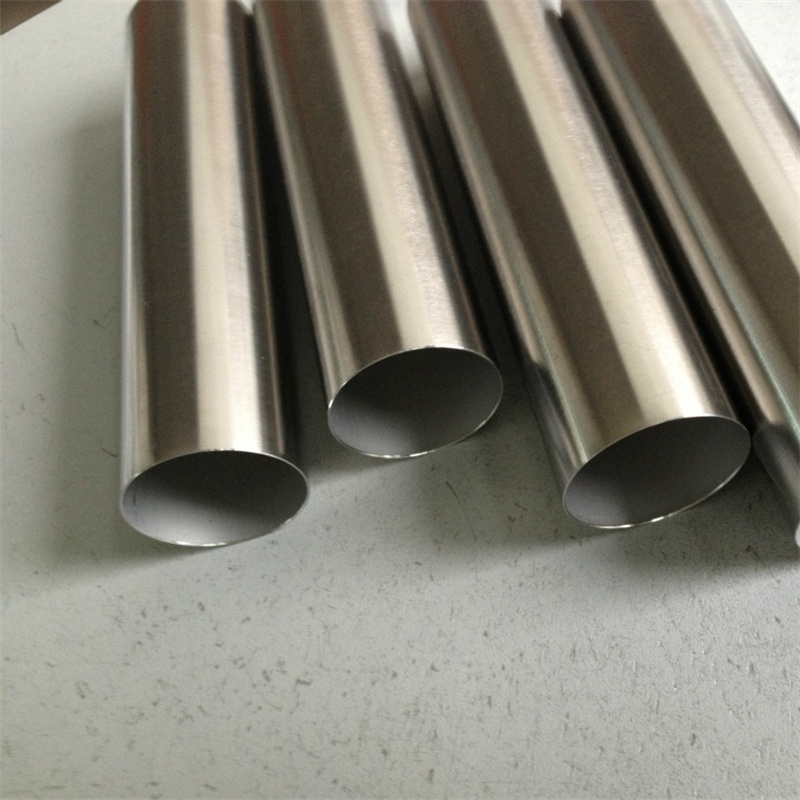

304 Precision Tube

304 Precision Tube is a high-quality tube made from stainless steel material (304) that offers a wide range of applications and excellent performance.

High Corrosion Resistance: 304 Precision Tube exhibits excellent corrosion resistance, making it highly resistant to most common corrosive media such as acids, alkalis, and salt solutions. It is suitable for pipeline systems handling corrosive media in industries like chemical, petroleum, and food processing.

Excellent Mechanical Properties: 304 Precision Tube possesses good strength and toughness, meeting the requirements for various stresses and operating conditions. It is suitable for applications that require resistance to high pressure, high temperature, and impact loads.

Outstanding Processability: 304 Precision Tube is easy to process and shape, allowing for the manufacturing of high-precision and high-polish tubes through methods like cold drawing, cold rolling, or cold extrusion. It can also undergo cutting, welding, and connecting operations to meet different application needs.

Good Heat Treatment Performance: 304 Precision Tube can be heat-treated (annealing, solution treatment, etc.) to improve its mechanical properties and corrosion resistance, making it suitable for more demanding process requirements.

Wide Range of Applications: 304 Precision Tube finds extensive applications in many industries. It is commonly used in pharmaceutical equipment, food processing equipment, chemical plants, automotive components, aerospace equipment, and building structures.

In summary, 304 Precision Tube is a high-quality stainless steel tubing with high corrosion resistance, excellent mechanical properties, and processability. It is suitable for various applications, including chemical, petroleum, food processing, pharmaceuticals, and construction industries.

Food Processing: Suitable for use in food and beverage processing equipment due to its corrosion resistance and hygienic properties.

Pharmaceutical Industry: Used in pharmaceutical manufacturing processes that require high purity and resistance to corrosion.

Automotive Components: Widely used in exhaust systems, fuel lines, and other automotive applications requiring corrosion resistance.

Construction: Applied in architectural structures, handrails, and decorative applications where aesthetic appeal and durability are essential.

Other Industries: The 304 Precision Tube finds applications in various industries, including chemical, petrochemical, and marine sectors.

Please note that the specifications may vary depending on the specific manufacturer or supplier. It is always recommended to refer to the product datasheet or contact the manufacturer for precise product information.

| Material | Stainless Steel (304) |

| Outer Diameter | [Specify the range] |

| Wall Thickness | [Specify the range] |

| Length | [Specify the standard length or custom length options] |

| Standard | [Specify the applicable industry standards, such as ASTM, ASME, EN, etc.] |

| Chemical Composition | Chromium (Cr): 18% - 20% Nickel (Ni): 8% - 10.5% Carbon (C): 0.08% max Manganese (Mn): 2% max Silicon (Si): 1% max Phosphorus (P): 0.045% max Sulfur (S): 0.03% max |

| Other alloying elements | [Specify any other relevant alloying elements and their composition] |

| Mechanical Properties | Yield Strength: [Specify the minimum value in MPa or ksi] Tensile Strength: [Specify the minimum value in MPa or ksi] Elongation: [Specify the minimum value as a percentage] |

| Corrosion Resistance | General Corrosion: The 304 Precision Tube exhibits good resistance to general corrosion in various environments, including atmospheric conditions. Pitting and Crevice Corrosion: It offers moderate resistance to pitting and crevice corrosion, particularly in chloride-containing solutions. Intergranular Corrosion: The 304 Precision Tube is resistant to intergranular corrosion after welding or exposure to high temperatures. |

| Welding Options | Welding Methods: The 304 Precision Tube can be welded using common methods such as TIG (GTAW) and MIG (GMAW). Welding Consumables: [Specify the recommended welding consumables, including filler materials and shielding gases, if applicable] |

316 and 316L stainless steel hot rolled plates are widely used in various industries due to their excellent corrosion resistance, high temperature strength, and exceptional mechanical properties. These plates are produced through a hot rolling process, where the steel is heated above its recrystallization temperature and then passed through a series of rollers to achieve the desired thickness.

Corrosion Resistance: Both 316 and 316L stainless steel exhibit excellent resistance to a wide range of corrosive environments, including acidic and chloride-containing solutions.

High Temperature Strength: These grades maintain their strength and integrity at elevated temperatures, making them suitable for applications involving heat or thermal cycling.

Mechanical Properties: 316 and 316L offer good tensile and yield strength, as well as excellent toughness, enabling them to withstand heavy loads and impacts.

Weldability: These stainless steels can be easily welded, allowing for the fabrication of complex structures and components.

Suitable for Food and Medical Industries: Due to their non-reactive nature, 316 and 316L are commonly used in food processing, pharmaceutical, and medical equipment where hygiene and compatibility are critical.

Chemical processing equipment

Heat exchangers

Pharmaceutical and medical equipment

Food and beverage industry machinery

Marine environments (boats, shipbuilding)

Oil and gas processing equipment

Pulp and paper industry machinery

Please note that this is a general product introduction, and specific technical specifications may vary depending on the manufacturer or supplier.