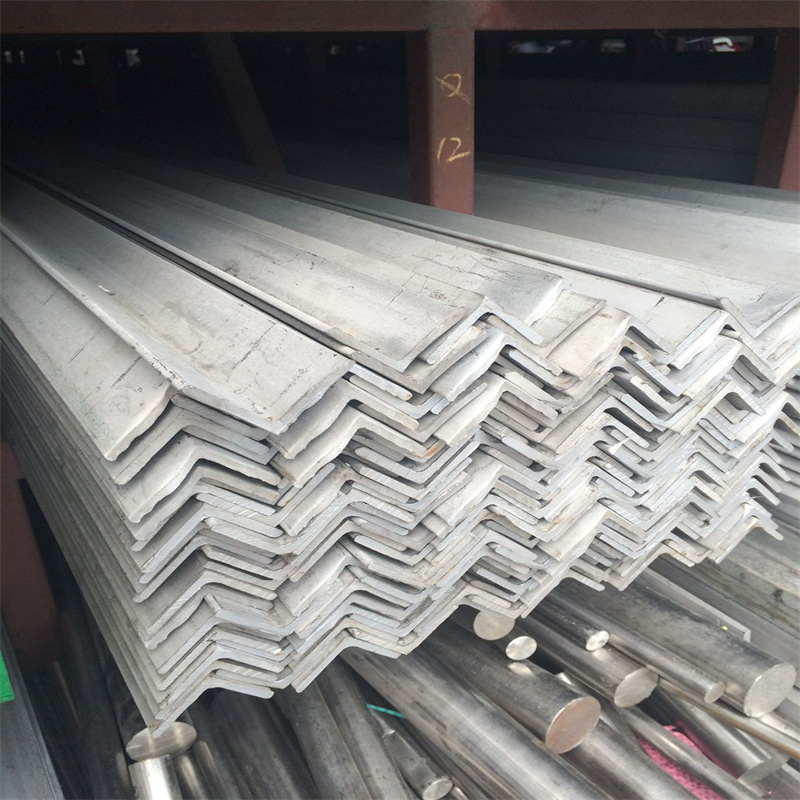

304 stainless steel angle steel

304 stainless steel angle bar, also known as 304 stainless steel L-shaped bar, is a high-quality stainless steel material widely used in various industries. With its excellent corrosion resistance, tensile strength, and durability, it has become an indispensable material in modern construction and engineering projects.

304 stainless steel angle bar is made from austenitic stainless steel, which has good corrosion resistance in various environments. It is non-magnetic and has excellent mechanical properties, including high tensile strength and impact resistance. The material is also easy to clean and maintain, reducing the need for frequent repairs and replacements.

Due to its unique properties, 304 stainless steel angle bar is widely used in various industries, including construction, transportation, chemical industry, and environmental protection. It is often used as a structural member to support bridges, towers, and other large structures. In addition, it can also be used as a reinforcing bar in concrete structures to improve the strength and durability of the structure.

The production process of 304 stainless steel angle bar mainly includes melting, casting, rolling, cutting, and heat treatment. To ensure the quality of the final product, each step of the production process requires strict quality control. The finished product is then inspected to ensure it meets the required standards and specifications.

In conclusion, 304 stainless steel angle bar is a high-quality material with excellent corrosion resistance, tensile strength, and durability. It has a wide range of applications in various industries and is an important structural member in modern construction and engineering projects. Its unique properties and wide application make it a valuable material for engineers and constructors to use in their projects.

| Element | Standard Range | Typical Range |

| Carbon (C) | ≤0.07-0.08% | - |

| Silicon (Si) | ≤1.00% | - |

| Manganese (Mn) | ≤2.00% | - |

| Phosphorus (P) | ≤0.05% | - |

| Sulfur (S) | ≤0.03% | - |

| Chromium (Cr) | 18.00-20.00% | - |

| Nickel (Ni) | 8.00-10.50% | - |

| Property | Test Method | Minimum Value |

| Tensile Strength, B (MPa) | ASTM A370 | ≥520 |

| Yield Strength, 0.2 (MPa) | ASTM A370 | ≥205 |

| Elongation, 5 (%) | ASTM A370 | ≥40 |

| Reduction of Area (%) | ASTM A370 | ≥60 |

| Hardness, HB | Brinell Hardness Test | ≤187 |

| Hardness, HRB | Rockwell Hardness Test | ≤90 |

| Hardness, HV | Vickers Hardness Test | ≤200 |

| Density (g/cm³) at 20°C | ASTM E1137 / E1127 | 7.93 |

| Melting Point (℃) | - | 1398-1454℃ |