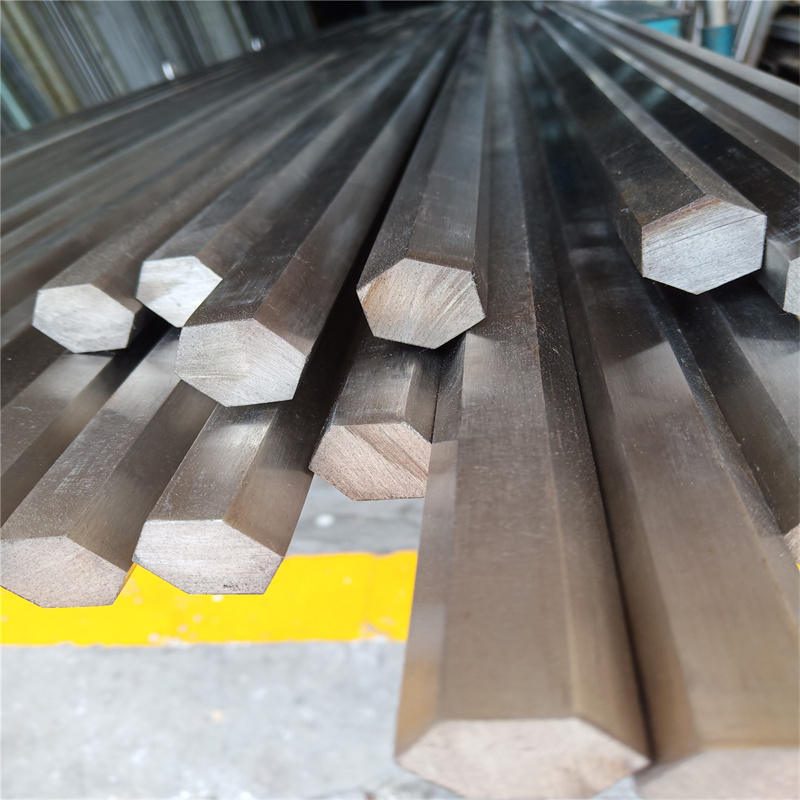

304 Stainless Steel Hexagonal Bar

The 304 stainless steel hexagonal bar is a high-quality material, widely used in various industries due to its excellent corrosion resistance, durability, and strength. With its unique hexagonal shape, this bar offers improved torsional strength and greater resistance to bending moments compared to standard round bars.

1.Corrosion Resistance: 304 stainless steel has excellent corrosion resistance due to its chromium-nickel content, making it suitable for use in corrosive environments such as chemical plants, sea water applications, and food processing facilities.

2.High Tensile Strength: The hexagonal bar offers greater tensile strength compared to round bars, providing greater structural integrity and support. This makes it suitable for use in heavy-duty applications where high loads and stresses are encountered.

3.Durability: 304 stainless steel is known for its exceptional durability, ensuring longevity in various environments. Whether exposed to harsh weather conditions or continuous use under demanding conditions, this bar maintains its integrity over time.

4.Easy Fabrication: The hexagonal cross-section offers better welding properties and ease of fabrication compared to round bars. It can be easily cut, bent, and welded without compromising its structural integrity.

5.Versatile Applications: The 304 stainless steel hexagonal bar is suitable for a wide range of applications including construction, mechanical equipment, piping systems, industrial frameworks, and more. It provides a cost-effective and durable solution for various engineering projects.

6.Corrosion Resistance Properties:304 stainless steel I-beam has good corrosion resistance and can resist erosion by environmental factors such as atmosphere, water, acid and alkali. Under normal use conditions, 304 stainless steel I-beams have a long service life and low maintenance costs, making them an ideal building material.

1.Construction: Used in the construction of bridges, buildings, and other structures requiring high tensile strength and corrosion resistance. The hexagonal shape offers greater shear strength, making it suitable for anchor bolts, reinforcement bars, and connection joints.

2.Mechanical Equipment: In machinery and equipment manufacturing, the 304 stainless steel hexagonal bar is used as a reinforcement member or structural support. It provides increased stiffness and durability to withstand continuous operation under heavy loads.

3.Piping Systems: In piping systems, the hexagonal bar is often used as a reinforcing bar or tie rod to maintain the integrity of the piping structure. It helps prevent buckling and ensures proper support is provided for the piping system.

4.Industrial Frameworks: The 304 stainless steel hexagonal bar is an ideal choice for industrial frameworks that require high durability and corrosion resistance. It is used in manufacturing equipment, conveyor systems, and other industrial supports that require stability and strength.

5.Other Applications: The versatility of the 304 stainless steel hexagonal bar extends to various other applications such as automotive components, furniture manufacturing, and marine applications where corrosion resistance and durability are essential.

In conclusion, the 304 stainless steel hexagonal bar offers exceptional corrosion resistance, high tensile strength, durability, and ease of fabrication. Its unique hexagonal shape provides improved torsional strength and bending resistance making it a suitable choice for a wide range of engineering applications where high performance and longevity are required.

| Product Name |

304 Stainless Steel Hexagonal Bar |

| Chemical composition | Element | Content (%) Chromium (Cr) 18.00 - 20.00 Nickel (Ni) 8.00 - 10.00 Manganese (Mn) ≤ 2.00 Silicon (Si) ≤ 1.00 Sulfur (S) ≤ 0.030 Phosphorus (P) ≤ 0.045 |

| Mechanical Properties | Item Value Yield Strength (MPa) ≥ 205 Tensile Strength (MPa) ≥ 520 Elongation (%) ≥ 40 Reduction of Area (%) ≥ 62 Impact Energy (J) ≥ 47 Hardness (Hv) ≤ 200 |

| Physical Properties | Item Value Thermal Conductivity (W/m·K) ≤ 16.3 Specific Heat Capacity (J/kg·K) ≥ 502 Thermal Expansion Coefficient (10^-6/K) ≤ 18.9 Density (g/cm³) = 8.00 Impact Energy (J) ≥ 47 Hardness (Hv) ≤ 200 |