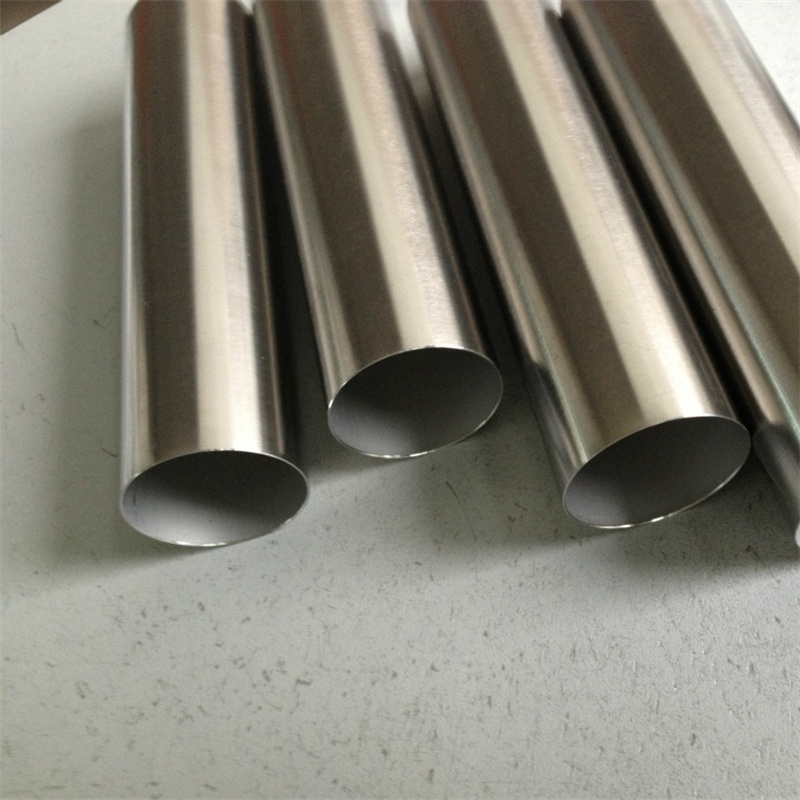

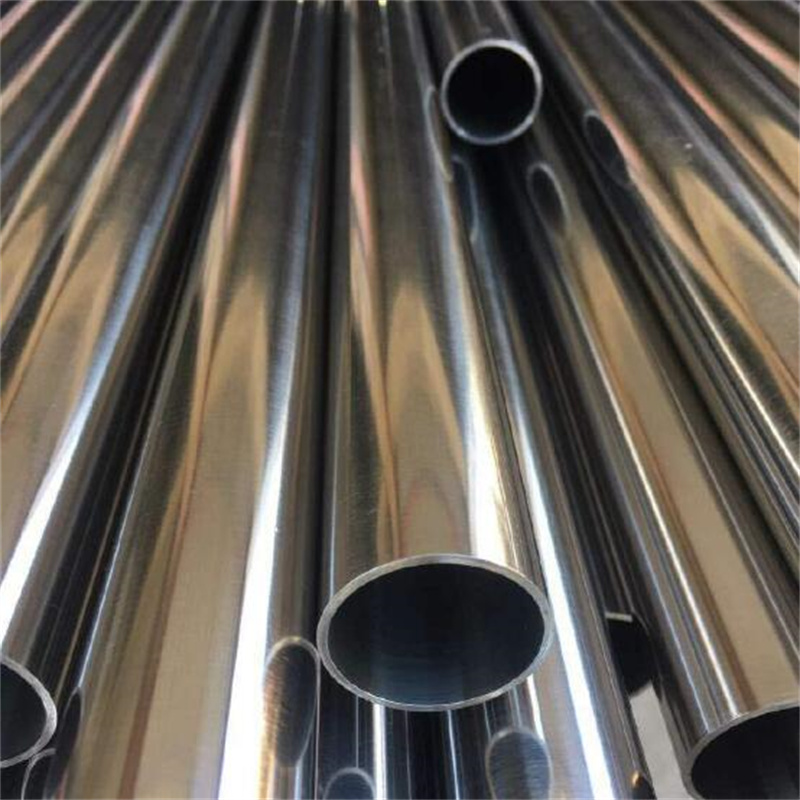

310S Precision Tube

Our 310S precision tubes are high-quality stainless steel tubes manufactured using grade 310S stainless steel. Known for its excellent heat resistance and corrosion resistance, 310S stainless steel is widely used in industries such as chemical, petroleum, power generation, and pharmaceuticals.

High Heat Resistance: 310S stainless steel exhibits exceptional heat stability, allowing it to withstand high temperatures and resist oxidation and corrosion at elevated operating conditions.

Corrosion Resistance: The 310S stainless steel tubes offer excellent resistance to corrosion in acidic, alkaline, and chloride-containing environments, making them suitable for challenging applications.

High Strength: Our precision tubes made from cold-worked 310S stainless steel exhibit high strength and toughness, enabling them to withstand high pressures and heavy loads.

Smooth Surface Finish: Our 310S precision tubes undergo precise polishing, resulting in smooth inner and outer surfaces that reduce frictional resistance and enhance fluid transfer efficiency.

Accurate Dimensions: The dimensions of our precision tubes are strictly controlled to ensure precise fitment and compatibility with various systems and components.

Versatile Applications: 310S precision tubes find applications in a wide range of industries, including heat exchangers, furnaces, burners, petrochemical plants, and power engineering.

To ensure product quality, our 310S precision tubes undergo stringent quality control measures, including:

Material Inspection: Thorough inspection of the chemical composition and mechanical properties of the raw materials.

Dimensional Accuracy: Precise measurements at various production stages to ensure compliance with specifications.

Surface Quality Evaluation: Assessment of surface finish smoothness and uniformity through polishing processes.

Corrosion Resistance Testing: Testing of tubes in corrosive environments to verify their corrosion resistance and durability.

Our 310S precision tubes comply with international quality standards and have obtained the following certifications:

ISO : Quality Management System Certification

ASTM : American Society for Testing and Materials Certification

CE : Conformité Européene Certification

For more information or inquiries about our 310S precision tubes, please contact our sales team.

| Material | Grade 310S Stainless Steel |

| Outer Diameter Range | From 1.0 mm to 50.8 mm (customizable as per requirements) |

| Wall Thickness Range | From 0.1 mm to 5.0 mm (customizable as per requirements) |

| Length Range | Typically 2 meters to 12 meters (customizable to other lengths) |

| Surface Finish | Ra≤0.8 micrometers (higher surface finishes available upon request) |

| Other Special Requirements | Customizable dimensions, materials, and surface treatments are available based on specific customer needs |

316 and 316L stainless steel hot rolled plates are widely used in various industries due to their excellent corrosion resistance, high temperature strength, and exceptional mechanical properties. These plates are produced through a hot rolling process, where the steel is heated above its recrystallization temperature and then passed through a series of rollers to achieve the desired thickness.

Corrosion Resistance: Both 316 and 316L stainless steel exhibit excellent resistance to a wide range of corrosive environments, including acidic and chloride-containing solutions.

High Temperature Strength: These grades maintain their strength and integrity at elevated temperatures, making them suitable for applications involving heat or thermal cycling.

Mechanical Properties: 316 and 316L offer good tensile and yield strength, as well as excellent toughness, enabling them to withstand heavy loads and impacts.

Weldability: These stainless steels can be easily welded, allowing for the fabrication of complex structures and components.

Suitable for Food and Medical Industries: Due to their non-reactive nature, 316 and 316L are commonly used in food processing, pharmaceutical, and medical equipment where hygiene and compatibility are critical.

Chemical processing equipment

Heat exchangers

Pharmaceutical and medical equipment

Food and beverage industry machinery

Marine environments (boats, shipbuilding)

Oil and gas processing equipment

Pulp and paper industry machinery

Please note that this is a general product introduction, and specific technical specifications may vary depending on the manufacturer or supplier.