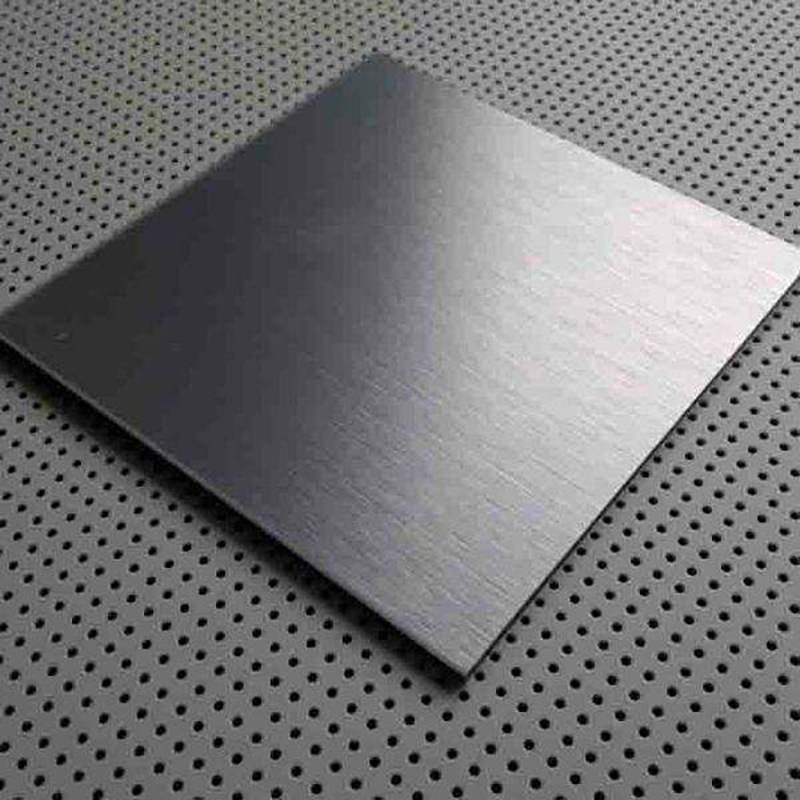

310S stainless steel brushed plate

The 310S stainless steel brushed plate is a high-grade product renowned for its excellent heat resistance, strength, and corrosion resistance. It is widely used in industries such as furnace manufacturing, petrochemical processing, and high-temperature applications.

| Material | 310S Stainless Steel |

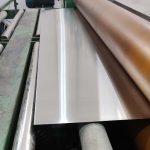

| Surface | Brushed finish |

| Thickness | Typically between 0.3mm and 3.0mm |

| Width | Usually ranges from 1000mm to 1500mm |

| Length | Customizable, up to six meters |

| Appearance | Brushed texture, creating a visually appealing and textured surface |

| Corrosion Resistance | Excellent resistance to high-temperature oxidation, as well as corrosion from sulfurous gases and other atmospheres |

| Applications | Heat treatment furnaces, kilns, radiant tubes, annealing covers, petroleum refining equipment, chemical processing, etc. |

| Chemical Composition | Carbon (C): 0.08% maximum Silicon (Si): 1.50% maximum Manganese (Mn): 2.00% maximum Phosphorus (P): 0.045% maximum Sulfur (S): 0.030% maximum Chromium (Cr): 24.00% - 26.00% Nickel (Ni): 19.00% - 22.00% |

310S Stainless Steel: This plate is manufactured using 310S stainless steel, which contains high levels of chromium and nickel. These elements provide exceptional resistance to oxidation, sulfidation, and high-temperature environments, making it suitable for applications where heat resistance is crucial.

Brushed Surface Finish: The plate undergoes a brushing process that creates a visually appealing matte finish. The brushed surface not only enhances the overall appearance but also helps to conceal minor imperfections, providing a clean and professional look.

Superior Heat Resistance: The 310S stainless steel brushed plate offers superior resistance to high temperatures. It maintains its strength and integrity even when exposed to elevated temperatures, making it ideal for use in furnaces, kilns, heat exchangers, and other high-temperature equipment.

Excellent Corrosion Resistance: With its high levels of chromium content, the 310S stainless steel brushed plate exhibits outstanding resistance to corrosive environments, including acids, alkalis, and gases. This property makes it suitable for applications in chemical processing plants and other corrosive environments.

High Strength and Durability: The 310S stainless steel brushed plate is known for its excellent mechanical properties, including high tensile strength and toughness. It can withstand heavy loads, impacts, and thermal cycles without deformation or loss of performance.

Versatility: This product finds extensive use in various industries, such as aerospace, power generation, and automotive. It is employed in applications such as exhaust systems, radiant tubes, heat treatment baskets, and other components where high-temperature and corrosion resistance are essential.

Easy Maintenance: The brushed surface finish on the plate requires minimal maintenance. Regular cleaning with mild detergents and non-abrasive cloths or sponges is sufficient to keep it looking pristine.

Environmental Considerations: Stainless steel, including 310S, is a sustainable material that can be recycled indefinitely without degradation. Choosing the 310S stainless steel brushed plate promotes eco-friendly practices and reduces environmental impact.

In summary, the 310S stainless steel brushed plate offers exceptional heat resistance, corrosion resistance, and durability. Its ability to withstand high temperatures and corrosive environments makes it a reliable choice for various industries where performance and longevity are paramount.