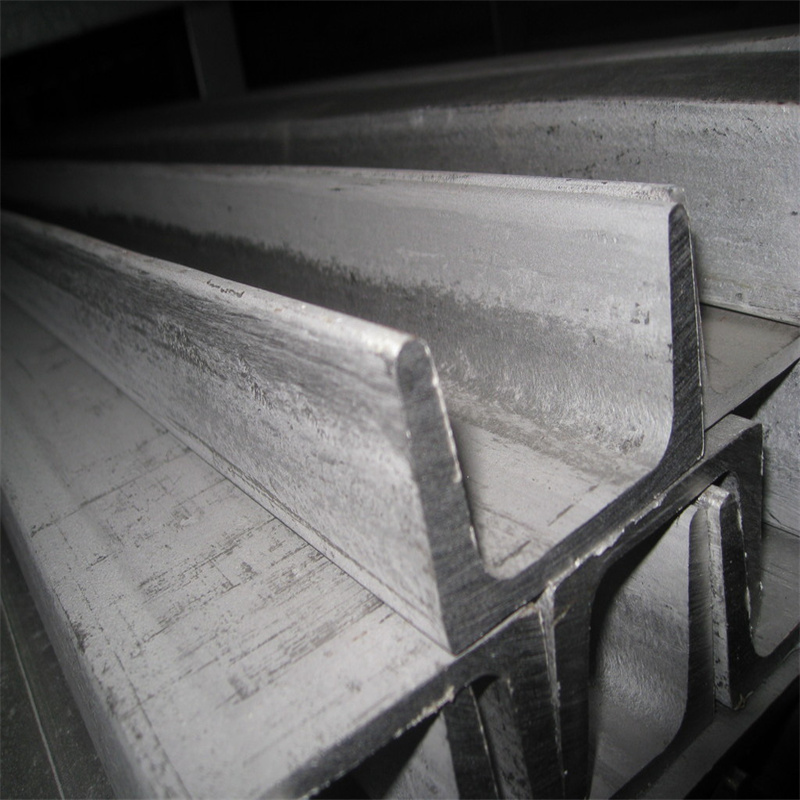

310S stainless steel channel

310S stainless steel channel steel, also known as 310S stainless steel hollow section, is a high-performance material used in a variety of engineering and construction applications. With its exceptional corrosion resistance and exceptional mechanical properties, 310S stainless steel channel steel has become a popular choice for a range of demanding applications.

310S stainless steel channel steel is a grade of austenitic stainless steel that offers excellent resistance to corrosion and oxidation. It has good mechanical strength and ductility, making it suitable for use in a wide range of load-bearing structures and components. Other key properties include:

High tensile strength

Good impact resistance

Excellent fatigue resistance

Easy to machine and weld

Due to its exceptional corrosion resistance and mechanical properties, 310S stainless steel channel steel is used in a variety of industries and applications, including:

Building and construction

Heavy machinery and equipment manufacturing

Marine engineering

Chemical processing plants

Power generation facilities

Automotive industry

Aerospace industry

Food processing industry

The production of 310S stainless steel channel steel involves several processes. The main steps include:

Melting and casting: The raw materials are melted and cast into ingots or billets.

Hot rolling: The ingots or billets are hot rolled into hollow sections using special rolling mills.

Annealing: The hot rolled hollow sections are annealed to improve their mechanical properties.

Surface treatment: The surface of the channel steel is treated to ensure corrosion resistance. This may involve passivation, pickling, or other surface enhancement techniques.

Quality control: Final inspection and testing are conducted to ensure that the finished product meets the required quality standards.

The English composition parameter table of 310S stainless steel channel steel provides its chemical composition and physical properties, which helps users understand the basic properties and application scope of the material.

310S stainless steel channel steel is a high-quality steel that is widely used in construction, bridges, ships, automobiles and other fields. Its English ingredient parameter list is as follows:

| Chemical Composition | C (carbon): ≤0.08% Si (silicon): ≤1.00% Mn (manganese): ≤2.00% P (phosphorus): ≤0.045% S (sulfur): ≤0.030% Ni (nickel): ≥72.00% Cr (chromium): ≤24.00% Mo (molybdenum): ≤1.50% Cu (copper): ≤0.75% N (nitrogen): ≤0.10% |

| Physical properties | Density: 8.0g/cm³ Melting point: 1397-1453℃ Tensile strength: ≥520MPa Yield strength: ≥205MPa Elongation: ≥40% Sectional shrinkage: ≥60% Hardness: ≤201HBW Elastic modulus: 200GPa Poisson's ratio: 0.348 |

316 and 316L stainless steel hot rolled plates are widely used in various industries due to their excellent corrosion resistance, high temperature strength, and exceptional mechanical properties. These plates are produced through a hot rolling process, where the steel is heated above its recrystallization temperature and then passed through a series of rollers to achieve the desired thickness.

Corrosion Resistance: Both 316 and 316L stainless steel exhibit excellent resistance to a wide range of corrosive environments, including acidic and chloride-containing solutions.

High Temperature Strength: These grades maintain their strength and integrity at elevated temperatures, making them suitable for applications involving heat or thermal cycling.

Mechanical Properties: 316 and 316L offer good tensile and yield strength, as well as excellent toughness, enabling them to withstand heavy loads and impacts.

Weldability: These stainless steels can be easily welded, allowing for the fabrication of complex structures and components.

Suitable for Food and Medical Industries: Due to their non-reactive nature, 316 and 316L are commonly used in food processing, pharmaceutical, and medical equipment where hygiene and compatibility are critical.

Chemical processing equipment

Heat exchangers

Pharmaceutical and medical equipment

Food and beverage industry machinery

Marine environments (boats, shipbuilding)

Oil and gas processing equipment

Pulp and paper industry machinery

Please note that this is a general product introduction, and specific technical specifications may vary depending on the manufacturer or supplier.