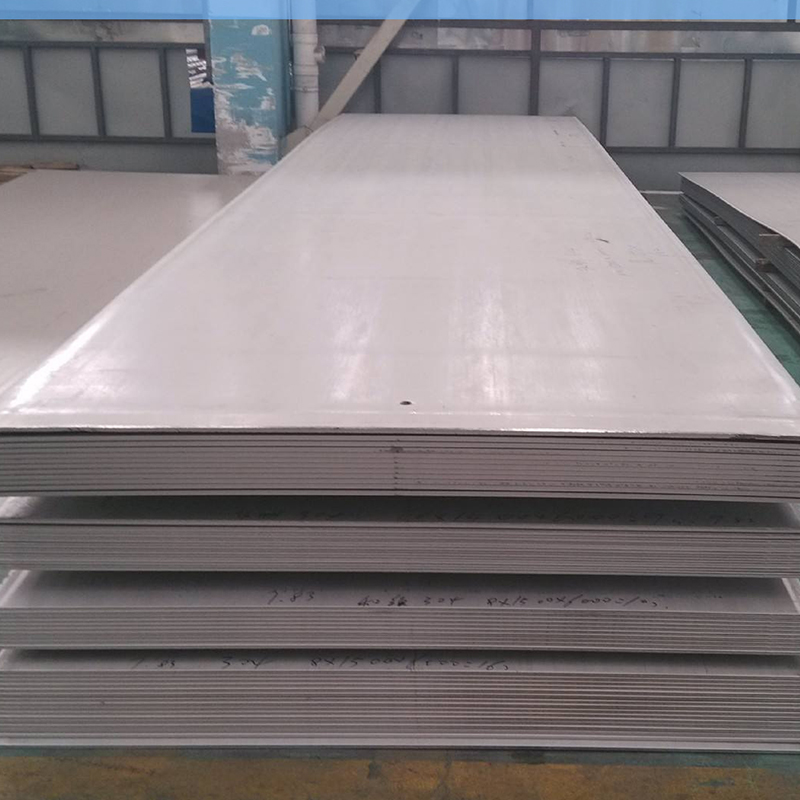

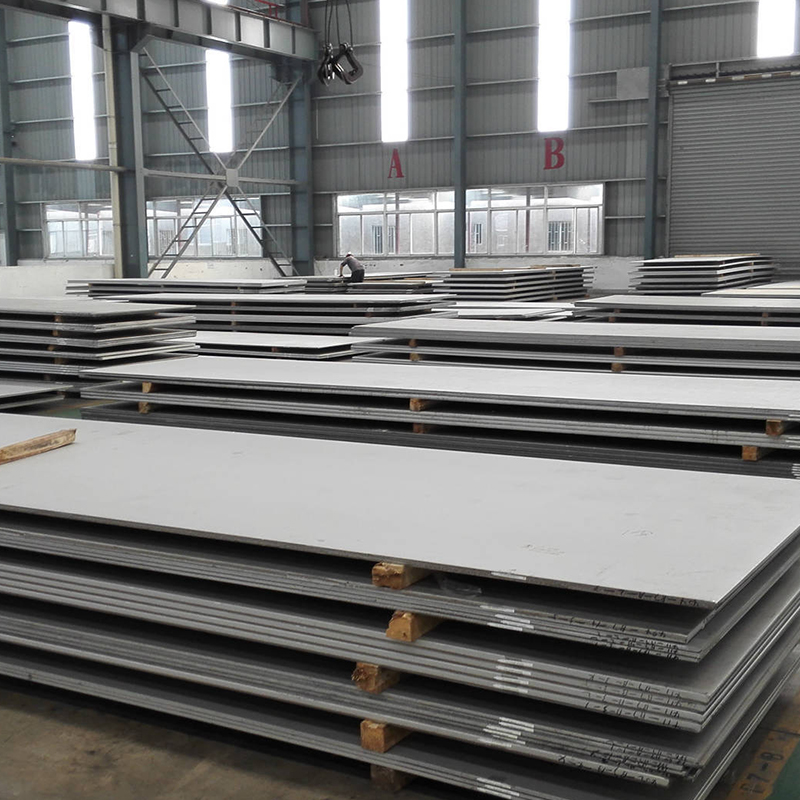

310S stainless steel cold rolled plate

310S stainless steel cold rolled plate is a high-quality metal product widely used in various industries. It is made from the 310S-grade stainless steel, which offers excellent resistance to high temperatures, oxidation, and corrosion.

| Material | 310S Stainless Steel |

| Form | Cold Rolled Plate |

| Thickness | 0.3mm - 6mm |

| Width | 1000mm - 2000mm |

| Length | 2000mm - 6000mm (or custom) |

| Surface Finish | 2B, BA, No.1, No.4, HL, etc. |

| Tolerance | As per standard or custom requirements |

| Hardness (HRB) | 95 maximum |

| Yield Strength | 210 MPa minimum |

| Tensile Strength | 520 MPa minimum |

| Elongation | 40% minimum |

| Density | 7.98 g/cm³ |

| Application | Carbon (C): 0.08% maximum Silicon (Si): 1.50% maximum Manganse(MN):2.00% maximum Phosphorus (P): 0.045% maximum Sulfur (S): 0.030% maximum Chromium (Cr): 24.00% - 26.00% Nickel (Ni): 19.00% - 22.00% |

Below are some key features and advantages of 310S stainless steel cold rolled plate:

1.High-temperature resistance: The 310S stainless steel cold rolled plate exhibits exceptional resistance to high temperatures, making it suitable for use in applications where heat resistance is crucial. It can withstand temperatures up to 1000°C (1832°F) without losing its strength or structural integrity.

2.Oxidation resistance: The plate resists oxidation and scaling at elevated temperatures, even in atmospheres containing sulfur compounds. This makes it ideal for use in industrial furnaces, heat treatment equipment, and other high-temperature environments.

3.Corrosion resistance: 310S stainless steel cold rolled plate possesses excellent resistance to corrosion, including both acidic and alkaline environments. It is highly resistant to pitting and crevice corrosion, making it suitable for use in chemical processing and marine applications.

4.Strength and ductility: The plate offers a combination of high strength and good ductility, allowing for easy fabrication and forming. It can be shaped, bent, welded, and machined to meet specific design requirements.

5.Versatility: 310S stainless steel cold rolled plate finds applications in various industries, including petrochemical, power generation, food processing, and pharmaceuticals. It is commonly used for manufacturing furnace components, kilns, radiant tubes, and other high-temperature equipment.

It's important to note that due to its high nickel and chromium content, 310S stainless steel cold rolled plate can be more expensive than other stainless steel grades. Therefore, careful evaluation of application requirements and consultation with experts are recommended before selecting the appropriate stainless steel grade.

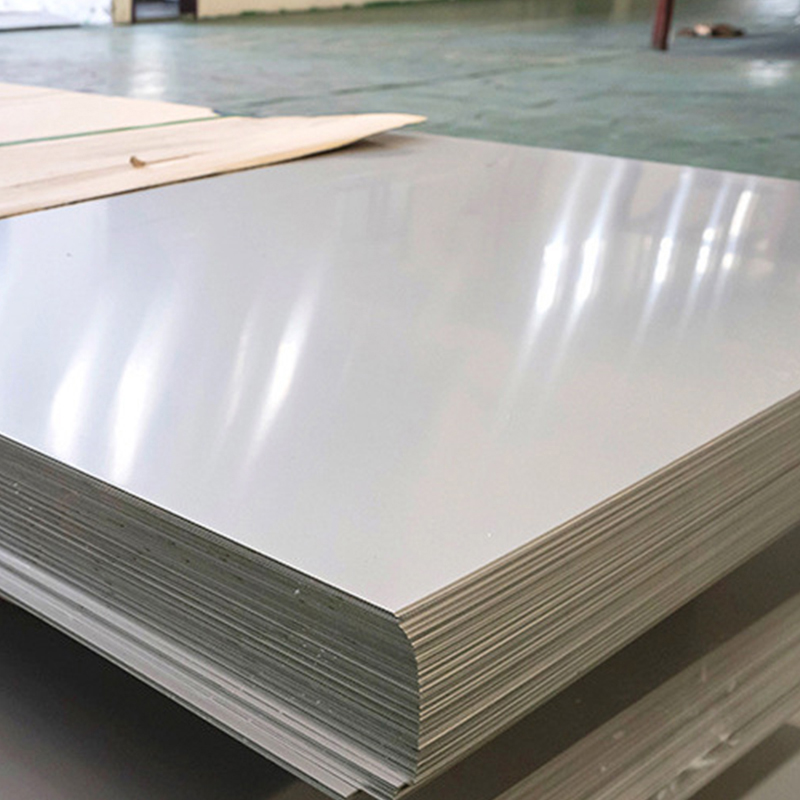

304 stainless steel hot rolled plate is a widely used and versatile metal product. It belongs to the austenitic stainless steel family, known for its excellent corrosion resistance, high temperature strength, and aesthetic appeal. This grade offers exceptional performance in various industries and applications.

| Grade | 304 |

| Manufacturing Method | Hot Rolled |

| Thickness Range | 3mm - 100mm |

| Width Range | Up to 2000mm |

| Length Range | Up to 6000mm |

| Surface Finish | No.1, 2B, BA, No.4, No.8, HL, etc. |

| Tensile Strength | ≥ 515 MPa |

| Yield Strength | ≥ 205 MPa |

| Elongation | ≥ 40% |

| Hardness (HB) | ≤ 201 (Brinell Hardness) |

| Density | 7.93 g/cm³ |

| Application | Carbon (C): ≤ 0.08% Silicon (Si): ≤ 1.00% Manganese (Mn): ≤ 2.00% Phosphorus (P): ≤ 0.045% Sulfur (S): ≤ 0.030% Chromium (Cr): 18.00 - 20.00% Nickel (Ni): 8.00 - 10.50% Silicon (Si): ≤ 1.00% |

Key features and advantages of 304 stainless steel hot rolled plate are as follows:

1.Excellent corrosion resistance: The plate exhibits excellent resistance to corrosion in a wide range of environments, including acidic, alkaline, and chloride-containing solutions. It withstands oxidation at high temperatures and resists pitting and crevice corrosion. This makes it suitable for applications in chemical processing, food industry, marine environments, and architectural structures.

2.High-temperature strength: 304 stainless steel hot rolled plate retains its mechanical properties at elevated temperatures, making it suitable for high-temperature applications. It has good heat resistance and can withstand thermal cycling without significant deformation or loss of strength. This property makes it ideal for use in heat exchangers, boilers, and furnace components.

3.Superior formability: The plate possesses excellent formability, allowing it to be easily shaped, bent, and fabricated into complex structures. It can be readily welded, machined, and formed using conventional techniques, enabling versatility in manufacturing processes.

4.Aesthetic appeal: 304 stainless steel hot rolled plate has a bright and reflective surface finish, providing an aesthetically pleasing appearance. Its smooth and polished surface makes it popular for decorative applications in architecture, interior design, and kitchen equipment.

5.Wide range of applications: The plate finds extensive use in various industries, including automotive, aerospace, pharmaceuticals, and construction. It is commonly employed in manufacturing equipment, appliances, utensils, sanitary fittings, and structural components that require a combination of corrosion resistance, strength, and aesthetics.

304 stainless steel hot rolled plate is a reliable and widely adopted material due to its excellent corrosion resistance, high-temperature strength, and versatility. When selecting 304 stainless steel hot rolled plate, it is essential to consider specific project requirements and consult with experts to ensure optimal performance for your application.