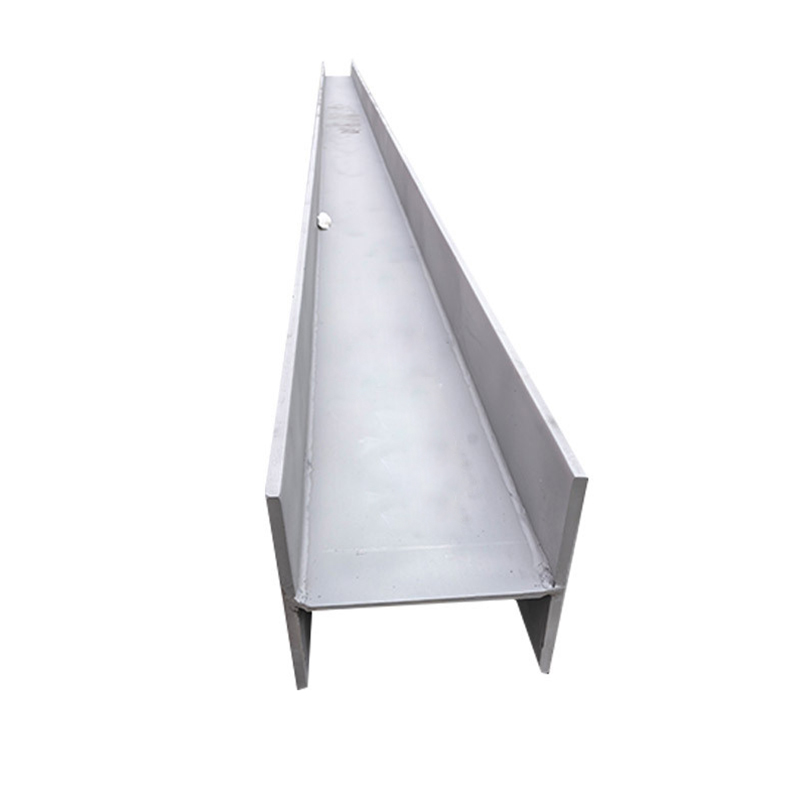

310S stainless steel i beam

The 310S stainless steel I-beams, a premium material choice for a range of structural applications. With its exceptional corrosion resistance and unmatched tensile strength, the 310S grade offers a unique combination of form and function.

310S stainless steel is a highly alloyed material, containing nickel and chromium, which provides excellent resistance to high temperatures and corrosive environments. This grade of steel is often used in severe conditions where longevity and durability are paramount. The inherent properties of 310S stainless steel translate into superior performance under demanding conditions, making it an ideal choice for a range of industrial, architectural, and engineering applications.

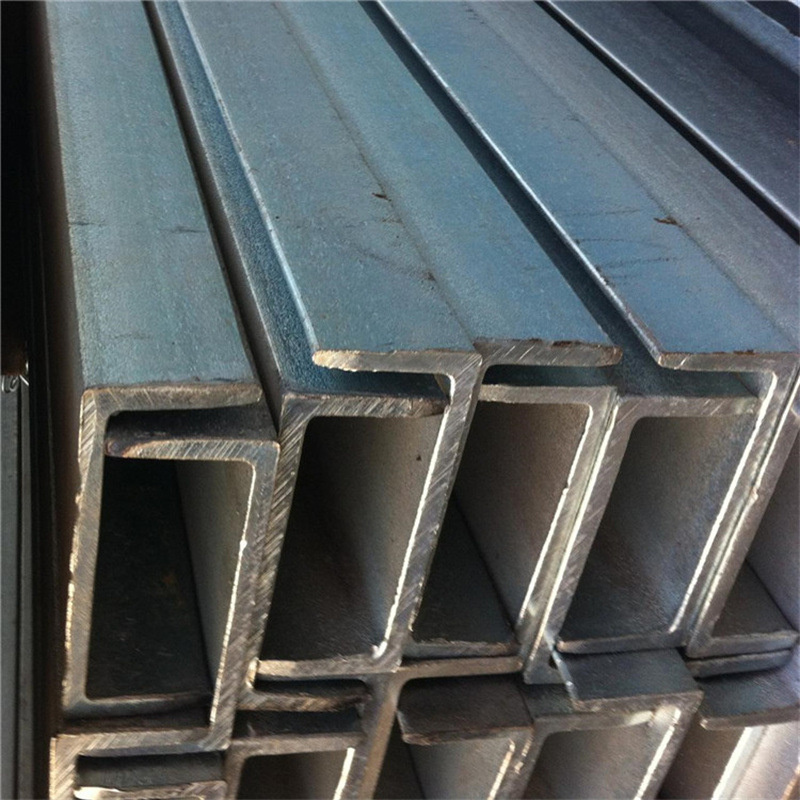

The I-beam shape offers a structurally efficient design, combining the advantages of both sections and channels. The flanges of the beam provide bending resistance, while the web supports the load. The unique cross-section geometry offers superior stability and torsional rigidity, making it suitable for a wide range of load-bearing applications.

In addition to its exceptional mechanical properties, the 310S stainless steel I-beams offer a sleek and modern aesthetic appeal. The polished finish showcases the beauty of the material, enhancing any structural design. The versatility of this grade of steel allows for creative freedom in design, making it an excellent choice for both functional and aesthetic considerations.

When selecting 310S stainless steel I-beams, you can rest assured that you are investing in a high-quality product that will stand the test of time. Whether for a commercial building, an industrial facility, or an architectural landmark, the 310S stainless steel I-beams will deliver exceptional performance and durability.

In conclusion, the 310S stainless steel I-beams are an exceptional choice for a range of structural applications. Their unique combination of corrosion resistance, tensile strength, and aesthetic appeal make them a top choice for designers and engineers seeking durability, functionality, and visual appeal in their projects.

| Product Name | 310L stainless steel I-beam |

| Introduction | 310L stainless steel I-beam is a high-quality, highly corrosion-resistant stainless steel material that is widely used in construction, bridges, chemical industry, electric power and other fields. Understanding its ingredient parameter list in English is important for the correct use and maintenance of this material. This article will introduce in detail the composition parameters of 310L stainless steel I-beam. |

| Chemical Composition | The chemical composition is the key factor that determines the performance of 310L stainless steel I-beam. According to the EN 10028-4 standard, the chemical composition of 310L stainless steel is as follows: C (carbon): ≤ 0.030 Si (silicon): ≤ 1.00 Mn (manganese): ≤ 2.00 P (phosphorus): ≤ 0.035 S (sulfur): ≤ 0.030 Cr (chromium): 22.00 - 24.00 Ni (nickel): 18.00 - 21.00 Mo (molybdenum): ≤ 0.75 N (nitrogen): ≤ 0.10 Cu (copper): ≤ 1.50 |

| Mechanical Properties | Mechanical properties are important indicators for evaluating the applicability of 310L stainless steel I-beams. According to the EN 10028-4 standard, its main mechanical performance parameters are as follows: Tensile Strength:≥ 620 MPa Yield Strength: ≥ 310 MPa Elongation: ≥ 35% Hardness: ≤ 213 HV Impact Strength: ≥ 62 J/ cm2 |

| Heat Treatment and Annealing | For optimal performance, 310L stainless steel I-beams require proper heat treatment and annealing. After heating to 1150°C and holding for a period of time, it should be quickly cooled to room temperature. The annealing treatment should be carried out at around 650°C and maintained for sufficient time to relieve stress and improve the plasticity of the material. |