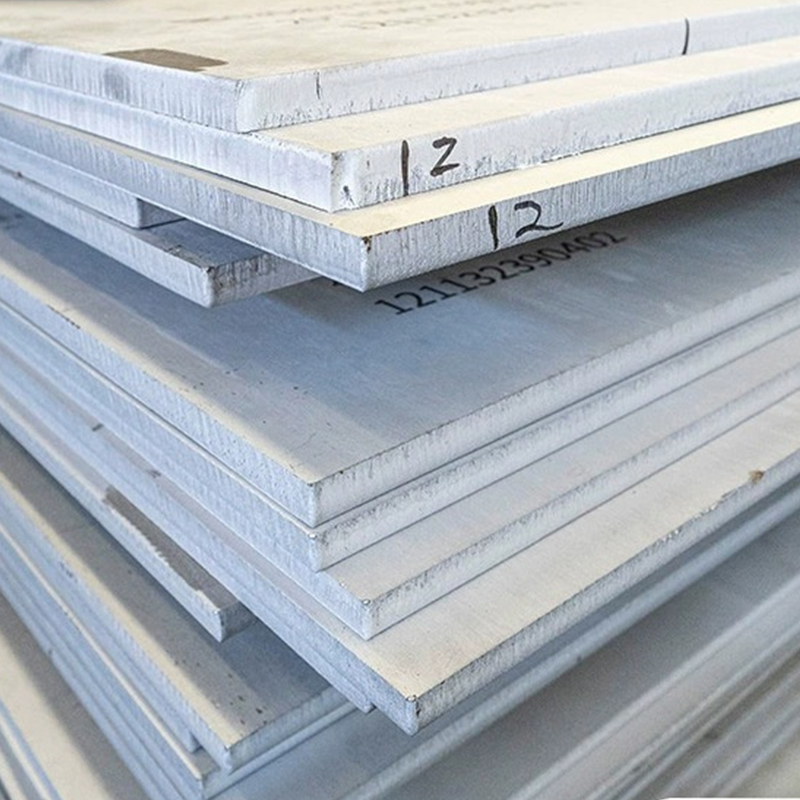

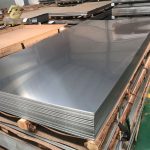

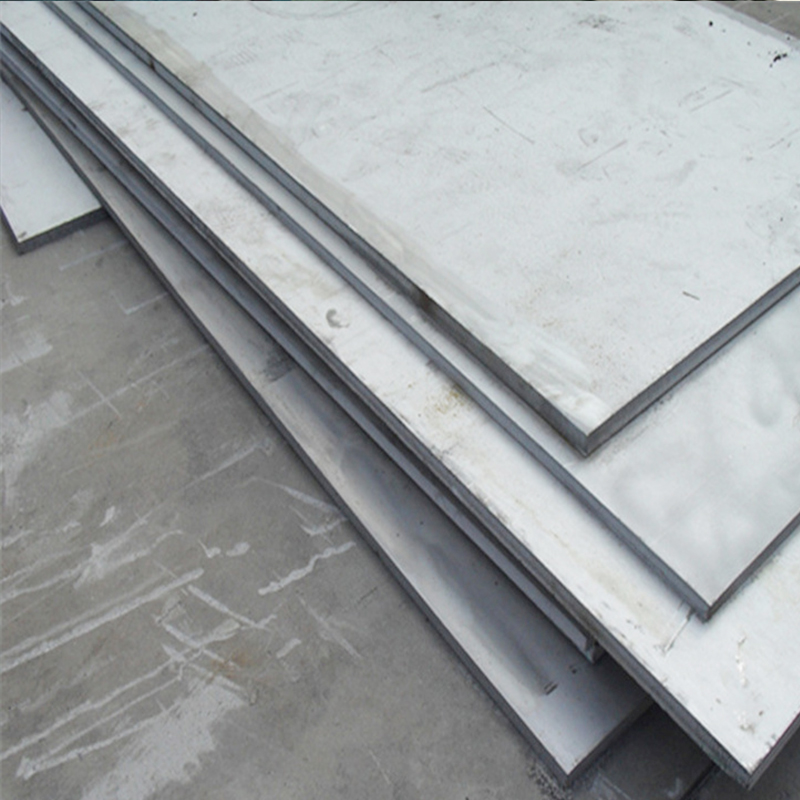

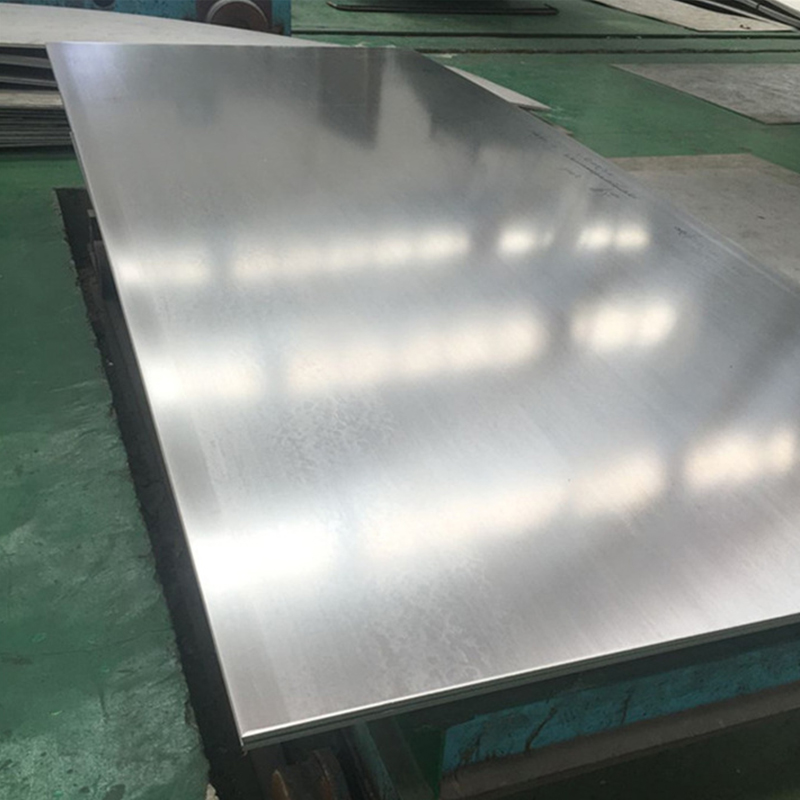

310S Stainless steel medium and thick plate

310S stainless steel medium and thick plate belong to the austenitic stainless steel family and are known for their exceptional high-temperature resistance and superior corrosion resistance. These medium and thick plate are widely used in industries that require materials capable of withstanding extreme heat environments. The thickness of 310S stainless steel medium and thick plate typically ranges from 3mm to 80mm.

| Grade | 310S |

| Product Name | Medium and Thick Plate |

| Thickness | Up to 100mm |

| Width Range | Up to 2000mm |

| Length Range | Up to 6000mm |

| Surface Finish | No.1, 2B, BA, No.4, No.8, HL, etc. |

| Tensile Strength | ≥ 515 MPa |

| Yield Strength | ≥ 205 MPa |

| Elongation | ≥ 40% |

| Hardness | ≤ 225 HB |

| Density | 8.00 g/cm³ |

| Heat Resistance | Up to 1100°C |

| Corrosion Resistance | Excellent resistance in high-temperature environments |

| Application | Furnace parts, heat treatment equipment, etc. |

| Chemical Composition | Carbon (C): 0.08% maximum Silicon (Si): 1.50% maximum Manganese (Mn): 2.00% maximum Phosphorus (P): 0.045% maximum Sulfur (S): 0.030% maximum Chromium (Cr): 24.00% - 26.00% Nickel (Ni): 19.00% - 22.00% |

High Temperature Resistance: 310S stainless steel medium and thick plate offer excellent resistance to high temperatures, making them suitable for applications in heat treatment furnaces, exhaust systems, and other high-temperature environments.

Superior Corrosion Resistance: These plates exhibit outstanding resistance to oxidation and corrosion in various environments, including oxidizing and reducing atmospheres.

Good Oxidation Resistance: 310S stainless steel forms a protective oxide scale at elevated temperatures, providing additional protection against oxidation.

Excellent Weldability: These plates have good weldability and can be readily welded using standard welding techniques, ensuring ease of fabrication and assembly.

Versatility: 310S stainless steel medium and thick plate find application in industries such as chemical processing, petroleum refining, power generation, and thermal processing due to their unique combination of high-temperature resistance and corrosion resistance.

Heat treatment equipment: Furnace components, radiant tubes, conveyor belts

Chemical processing industry: Reactors, tanks, pipelines

Power generation: Boiler components, heat exchangers

Thermal processing industry: Annealing boxes, retorts, muffles

Petrochemical industry: Furnace tubes, reformer tubes, flares

Exhaust systems in automotive and aerospace applications