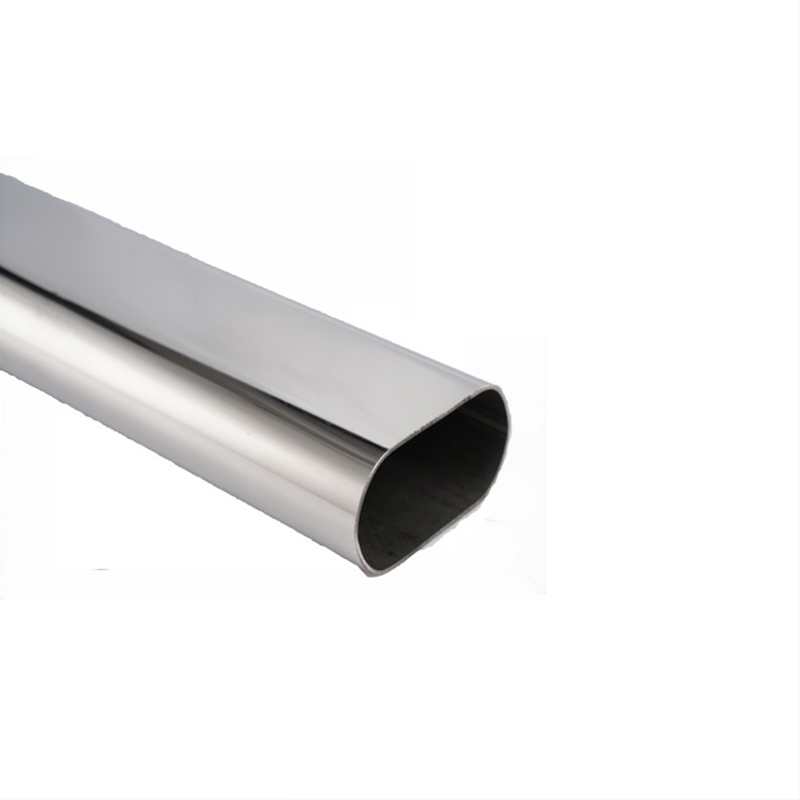

310S Stainless Steel Oval Tube

310S stainless steel oval tube is a high-performance product, offering exceptional strength and corrosion resistance. Let's delve into its key elements, manufacturing process, unique features, and diverse applications.

The foundation of 310S stainless steel oval tube lies in its composition, which primarily consists of iron, chromium, and nickel. These alloying elements provide the tube with its exceptional corrosion resistance, making it suitable for a wide range of environments.

The manufacturing process of 310S stainless steel oval tube is complex and rigorous. It begins with the hot-rolling of slabs, followed by the cold-rolling process to achieve the desired shape and thickness. The tube undergoes a series of quality checks at every stage to ensure its dimensional accuracy and material purity.

The key feature of 310S stainless steel oval tube is its high yield strength, making it an excellent choice for structural applications. It also boasts excellent formability, which enables it to be bent, twisted, or flattened without fracturing. Furthermore, its unique corrosion resistance makes it an excellent option for outdoor applications or in corrosive environments.

The applications of 310S stainless steel oval tube are diverse. It is commonly used in the construction industry for supports, frames, and in reinforced concrete structures. Additionally, it finds use in the automotive industry for exhaust systems and in chemical processing plants due to its corrosion resistance. Furthermore, it is employed in heat exchangers, pipelines, and various other industrial applications that require high durability and corrosion resistance.

| Stainless Steel Oval Tube | |

| Standard: | ASTM,GB,JIS,AISI,EN,DIN |

| Grade: | 201/304/316L/310S/254/2205/2507/904L, etc. |

| Size: | Customized |

| Edge: | Mill Edge,Slit Edge |

| Surface: | 2B |

| Packing: | Standard Export Pack or Customized |

| Lead Time: | 7~14 days |