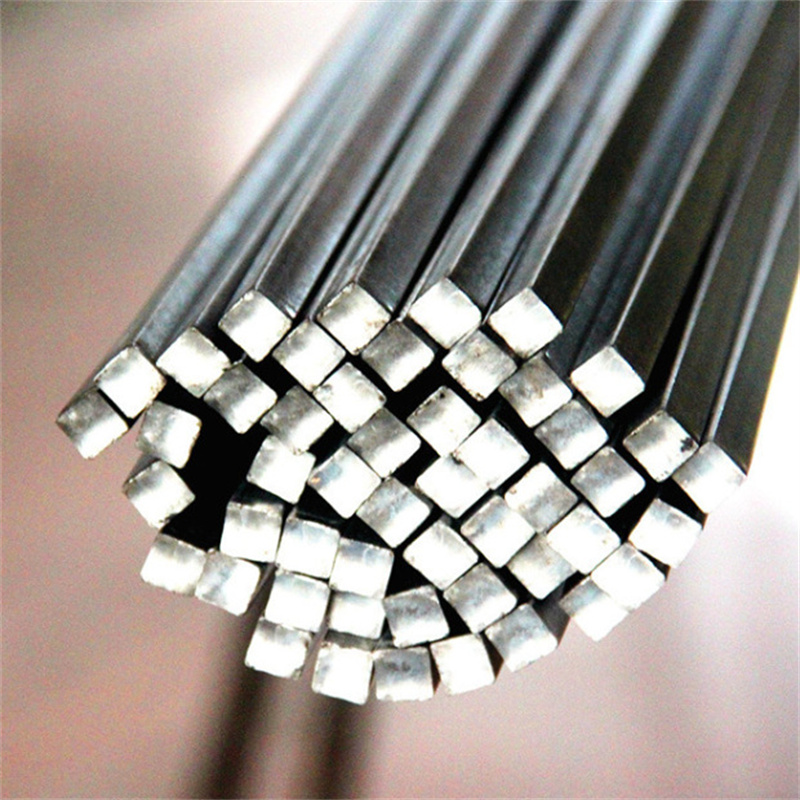

310S stainless steel square steel

310S stainless steel square steel, also known as 310S stainless steel angle iron, is a high-performance stainless steel product made of 310S stainless steel. It is widely used in the fields of architecture, decoration, mechanical equipment, automobiles, ships, chemical industry and other industries due to its excellent corrosion resistance, high strength and good processing performance.

Excellent corrosion resistance: 310S stainless steel square steel has good corrosion resistance in various environments, which can effectively resist corrosion and extend service life.

High strength: 310S stainless steel square steel has good tensile strength, yield strength and impact toughness, which can meet the requirements of various engineering applications.

Good processing performance: 310S stainless steel square steel has good cold and hot processing performance, easy to cut, weld and process, and has strong plasticity and ductility.

Beautiful appearance: The surface of 310S stainless steel square steel is bright and smooth, with strong metallic luster, which can be used for decorative and functional purposes.

310S stainless steel square steel is widely used in the following fields:

Architecture: It can be used as a supporting structure in the construction of bridges, high-rise buildings, tunnels and other facilities. It can also be used as a decorative material for curtain walls, facades and other surfaces.

Mechanical equipment: It can be used as a structural member in various mechanical equipment, such as machine tools, automobiles, ships and other transportation equipment. It has good corrosion resistance and long service life.

Chemical industry: It can be used in various chemical reactors, tanks and pipelines to resist corrosion and extend service life.

Other industries: It can also be used in the fields of electricity, petroleum, environmental protection and other industries due to its good corrosion resistance and processing performance.

| Material | 310S Stainless Steel Square Bar |

| Chemical composition | Carbon (C): ≤ 0.08% Manganese (Mn): ≤ 2.00% Silicon (Si): ≤ 1.00% Phosphorus (P): ≤ 0.045% Sulfur (S): ≤ 0.030% Chromium (Cr): 22.00-24.00% Nickel (Ni): 19.00-22.00% Molybdenum (Mo): ≤ 1.00% Titanium (Ti): ≤ 0.75% Aluminum (Al): ≤ 0.50% |

| Mechanical Properties | Yield Strength: ≥210 ksi Tensile Strength: ≥480 ksi Elongation: ≥35% Impact Strength: ≥12 ft-lb Hardness: ≤210 BHN |

| Mechanical Properties | Yield Strength: ≥ 215 ksi Tensile Strength: ≥ 315 ksi Elongation: ≥ 35% in 2" Reduction of Area: ≥ 45% in 2" Hardness: ≤ 213 Brinell |

| Physical Properties | Thermal Conductivity: ≤ 16.5 W/m·K at 20°C Thermal Expansion: ≤ 18.5 μm/m·K at 20°C Specific Heat: ≤ 0.11 kJ/kg·K at 20°C Linear Expansion: ≤ 12.3 μm/m at 20°C per 100°C increase in temperatureThermal Density: ≥ 8.0 g/cm³ at 20°C |