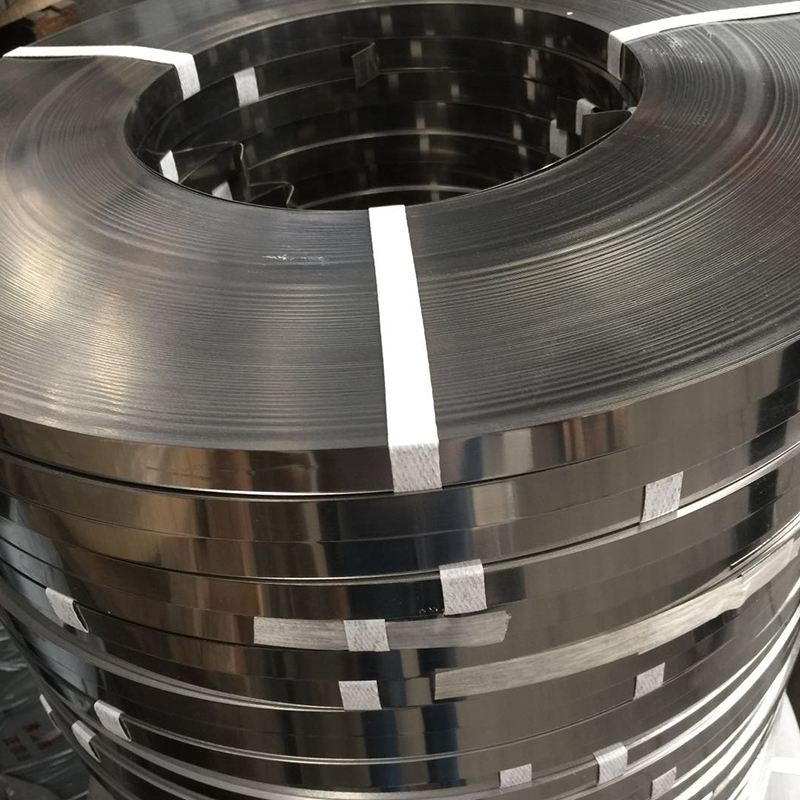

310S Stainless Steel Strip Coils

310S Stainless Steel Strip Coils, is a high-grade alloy that offers exceptional resistance to corrosion and high temperatures. It is widely used in various industries due to its unique combination of properties.

| Stainless Steel Strip Coil | |

| Standard: | ASTM,GB,JIS,AISI,EN,DIN |

| Grade: | 201/304/316L/310S/254/2205/2507/904L, etc. |

| Width(mm): | Min. 10.0mm |

| Thickness(mm): | 0.15mm-10.0mm or Customized |

| Surface: | No.1,No.3,No.4,TR,HL,2D,2B,BA,8K |

| Packing: | Standard Export Pack or Customized |

| Lead Time: | 7~14 days |

310S stainless steel belongs to the austenitic family, which means it has excellent formability and is non-magnetic. It is also characterized by its high chromium and nickel content, providing exceptional resistance to corrosion and oxidation. The addition of sulfur boosts its resistance to high-temperature environments, making it suitable for applications that require exposure to extreme heat.

The versatility of 310S stainless steel strip makes it suitable for a range of applications. It is commonly used in the production of kitchenware, utensils, and appliances that require resistance to high temperatures and corrosion. It is also employed in the automotive industry for components that require longevity and durability. In the construction industry, 310S stainless steel is used for roofing, cladding, and other exterior applications where durability and corrosion resistance are essential.

The production of 310S stainless steel strip involves several complex processes. The initial step involves the smelting of the raw materials, which typically includes chromium, nickel, and iron. The mixture is then refined and undergoes various heat treatments to achieve the desired chemical composition and microstructure.

After the material is cast into ingots, it undergoes a series of hot and cold rolling processes to achieve the desired thickness and mechanical properties. The surface of the strip may be polished or brushed to remove any imperfections and enhance its appearance. Finally, the strip is cut to length or coiled for convenient handling and transportation.

The production of 310S stainless steel strip requires precise control of alloying elements, processing conditions, and annealing cycles. Any deviation from the optimal processing parameters can affect the material's corrosion resistance, tensile strength, and other critical properties. Therefore, it is essential to use state-of-the-art technology and quality control methods to ensure consistent production of high-quality 310S stainless steel strip.

In conclusion, 310S stainless steel strip offers exceptional resistance to corrosion and high temperatures, making it an ideal choice for a variety of applications. Its unique combination of properties, coupled with its ease of processing and versatility, makes it a valuable material in various industries. However, its production requires precise control of alloying elements and processing parameters to ensure consistent quality and performance.