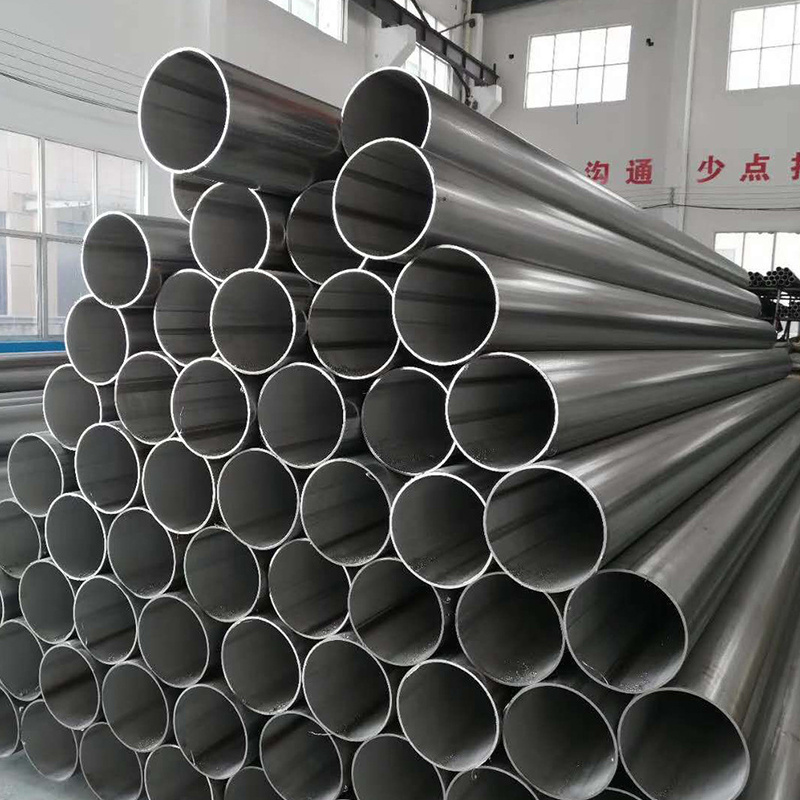

310S Welded Pipe

The 310S welded pipe is a type of stainless steel pipe made from high-quality 310S stainless steel material. It offers excellent resistance to high temperatures and corrosion, making it suitable for various industrial applications.

High temperature resistance: The 310S welded pipe exhibits exceptional resistance to high temperatures, making it suitable for applications involving extreme heat.

Corrosion resistance: It provides excellent resistance against corrosion, especially in harsh environments containing sulfuric acid, nitric acid, and other corrosive substances.

Versatile applications: The 310S welded pipe finds its utility in chemical processing plants, oil refineries, power generation facilities, food processing equipment, and many other industrial sectors.

Compliance and certifications: The product is manufactured according to international standards and specifications, ensuring quality.Certifications such as ISO 9001, CE, PED, AD2000, etc., may be provided by the manufacturer.

The 310S welded pipe is made from stainless steel grade 310S, which contains the following elements:

| Material | 310S Stainless Steel |

| Size Range | 1/2" - 48" (DN15 - DN1200) |

| Thickness | 0.5mm - 60mm |

| Length | 6 meters, or as per customer requirements |

| Standard | ASTM A312, ASTM A249, ASTM A269, ASTM A270, etc |

| Surface Finish | Pickling, Annealing, Polishing, etc. |

| Connection Type | Butt Welded, Socket Welded |

| Application | Chemical industry, Petrochemical industry, Oil & Gas industry, Food industry, etc. |

| Chromium (Cr) | The predominant element in stainless steel, chromium provides excellent corrosion resistance and helps enhance the pipe's overall strength and durability. In 310S, the chromium content typically ranges from 24% to 26%. |

| Nickel (Ni) | Nickel improves the ductility and toughness of the stainless steel, making it more resistant to cracking and deformation at high temperatures. The nickel content in 310S is generally around 19% to 22%. |

| Carbon (C) | Carbon is added in controlled amounts to improve the high-temperature strength and hardness of the stainless steel. In 310S, the carbon content is typically limited to a maximum of 0.08%. |

| Manganese (Mn) | Manganese enhances the mechanical properties of stainless steel, including its tensile strength and work-hardening ability. The manganese content in 310S is usually around 2% to 2.5%. |

| Silicon (Si) | Silicon is commonly added to stainless steel to improve its resistance to oxidation and scaling at high temperatures. In 310S, the silicon content is typically between 1% and 1.5%. |

| Other Elements | Trace amounts of other elements might be present in stainless steel, such as phosphorus (P), sulfur (S), and small quantities of various alloying elements like molybdenum (Mo) and copper (Cu). These additional elements can affect specific properties or processing characteristics of the material. |