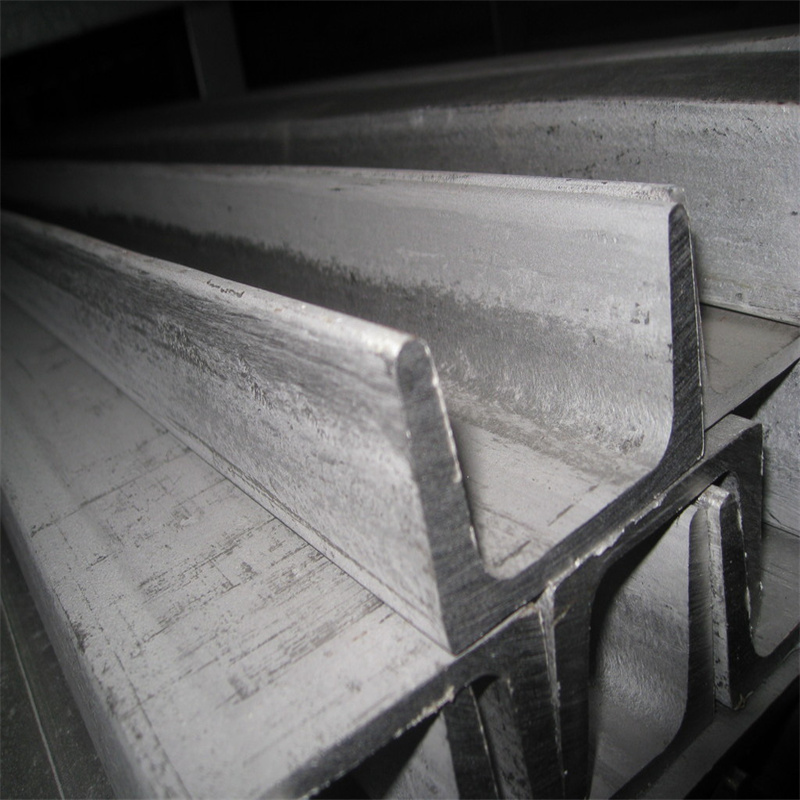

316L stainless steel channel

316L stainless steel channel steel, also known as 316L austenitic stainless steel channel steel, belongs to austenitic stainless steel grades. It has good corrosion resistance, high temperature resistance, and excellent process performance. 316L stainless steel channel steel is widely used in the fields of chemical industry, petroleum, marine engineering, paper making, etc.

Good corrosion resistance: 316L stainless steel channel steel has excellent corrosion resistance in various corrosive media. It can replace some copper and other materials in the process of chemical equipment and petroleum equipment.

High temperature resistance: 316L stainless steel channel steel has good high temperature resistance. It can be used in high temperature environments up to 800℃.

Excellent process performance: 316L stainless steel channel steel has good plasticity and weldability. It is easy to process and weld, and has a wide range of processing methods.

316L stainless steel channel steel is widely used in the fields of chemical industry, petroleum, marine engineering, paper making, etc. It can be used as structural materials for chemical equipment, oil equipment, shipbuilding, offshore platforms, pipelines, tanks, reactors, heat exchangers, pressure vessels, and other fields.

The production process of 304 stainless steel angle bar mainly includes melting, casting, rolling, cutting, and heat treatment. To ensure the quality of the final product, each step of the production process requires strict quality control. The finished product is then inspected to ensure it meets the required standards and specifications.

316L stainless steel channel steel is generally produced by hot rolling or cold rolling method. Hot rolling method refers to rolling the steel after heating to a certain temperature range to obtain the desired shape and size of the steel. Cold rolling method refers to rolling the steel at room temperature to obtain the desired shape and size of the steel. In order to ensure the quality of the steel, the heating temperature and rolling process parameters need to be strictly controlled during the production process.

316L stainless steel channel steel has excellent corrosion resistance and can maintain stable performance in various harsh environments. Its corrosion resistance is better than 304 stainless steel, especially in environments containing chloride ions.

316L stainless steel channel steel has good high temperature performance and can maintain excellent mechanical properties and corrosion resistance at higher temperatures. Its operating temperature range is usually between -20°C and 260°C.

In short, 316L stainless steel channel steel is widely used in various industrial fields such as petrochemical industry, marine engineering, pharmaceuticals, etc. due to its excellent chemical composition, mechanical properties, corrosion resistance and high temperature performance. By understanding its English composition parameter list, you can better understand its performance and application range, and thus better select and apply this high-quality metal material.

| Chemical Composition | C (carbon): ≤ 0.030 Si (silicon): ≤ 1.00 Mn (manganese): ≤ 2.00 P (phosphorus): ≤ 0.045 S (sulfur): ≤ 0.030 Ni (Nickel): 10.00 - 14.00 Cr (chromium): 16.00 - 18.50 Mo (molybdenum): 2.00 - 3.00 Cu (copper): ≤ 1.00 N (nitrogen): ≤ 0.10 |

| Mechanical behavior | Tensile strength: ≥ 485 MPa Yield strength: ≥ 210 MPa Elongation: ≥ 45% Hardness: ≤ 217 HB |

316 and 316L stainless steel hot rolled plates are widely used in various industries due to their excellent corrosion resistance, high temperature strength, and exceptional mechanical properties. These plates are produced through a hot rolling process, where the steel is heated above its recrystallization temperature and then passed through a series of rollers to achieve the desired thickness.

Corrosion Resistance: Both 316 and 316L stainless steel exhibit excellent resistance to a wide range of corrosive environments, including acidic and chloride-containing solutions.

High Temperature Strength: These grades maintain their strength and integrity at elevated temperatures, making them suitable for applications involving heat or thermal cycling.

Mechanical Properties: 316 and 316L offer good tensile and yield strength, as well as excellent toughness, enabling them to withstand heavy loads and impacts.

Weldability: These stainless steels can be easily welded, allowing for the fabrication of complex structures and components.

Suitable for Food and Medical Industries: Due to their non-reactive nature, 316 and 316L are commonly used in food processing, pharmaceutical, and medical equipment where hygiene and compatibility are critical.

Chemical processing equipment

Heat exchangers

Pharmaceutical and medical equipment

Food and beverage industry machinery

Marine environments (boats, shipbuilding)

Oil and gas processing equipment

Pulp and paper industry machinery

Please note that this is a general product introduction, and specific technical specifications may vary depending on the manufacturer or supplier.