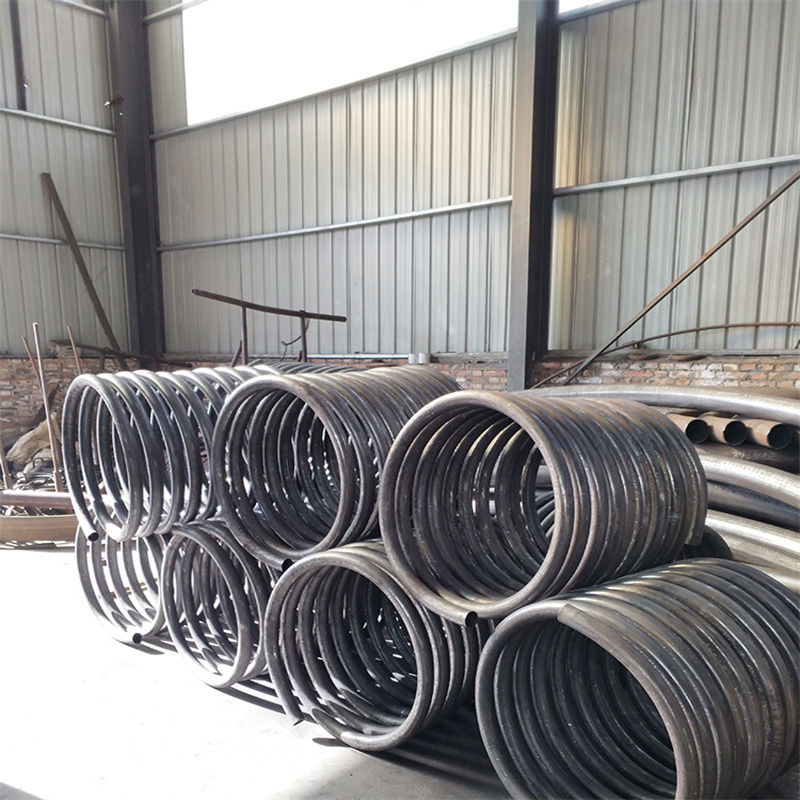

316L Stainless steel coil tube

316L stainless steel coil tubes are a highly versatile product, finding applications across various industries. The tubes are made from 316L grade stainless steel, a material known for its exceptional corrosion resistance and exceptional strength.

The production process of 316L stainless steel coil tubes involves several complex steps. First, the raw material is melted and poured into ingots. These ingots are then hot rolled into sheets, which are further processed into tubes. The tubes undergo rigorous quality checks at every stage of production to ensure they meet stringent standards of dimensional accuracy and surface finish.

The key characteristics of 316L stainless steel coil tubes include their exceptional corrosion resistance, high tensile strength, and excellent formability. The tubes also exhibit good weldability and can be bent and shaped easily without cracking or splitting.

The widespread applications of 316L stainless steel coil tubes include the chemical processing industry, where they are used for handling corrosive chemicals. Other applications include water treatment facilities, food processing plants, and the transportation industry, where they are used in the manufacturing of vehicles like automobiles and trains.

In conclusion, 316L stainless steel coil tubes are a highly versatile product, offering exceptional corrosion resistance, high tensile strength, and excellent formability. Their wide range of applications makes them an indispensable component in various industries.

| Stainless Steel Coil TUBE | |

| Standard: | ASTM,GB,JIS,AISI,EN,DIN |

| Grade: | 201/304/316L/310S/254/2205/2507/904L, etc. |

| Size: | Customized |

| MOQ: | 500KG |

| Color: | Nickel White |

| Packing: | Standard Export Pack or Customized |

| Lead Time: | 14~21 days |