316L Stainless Steel Cold-Rolled Coils

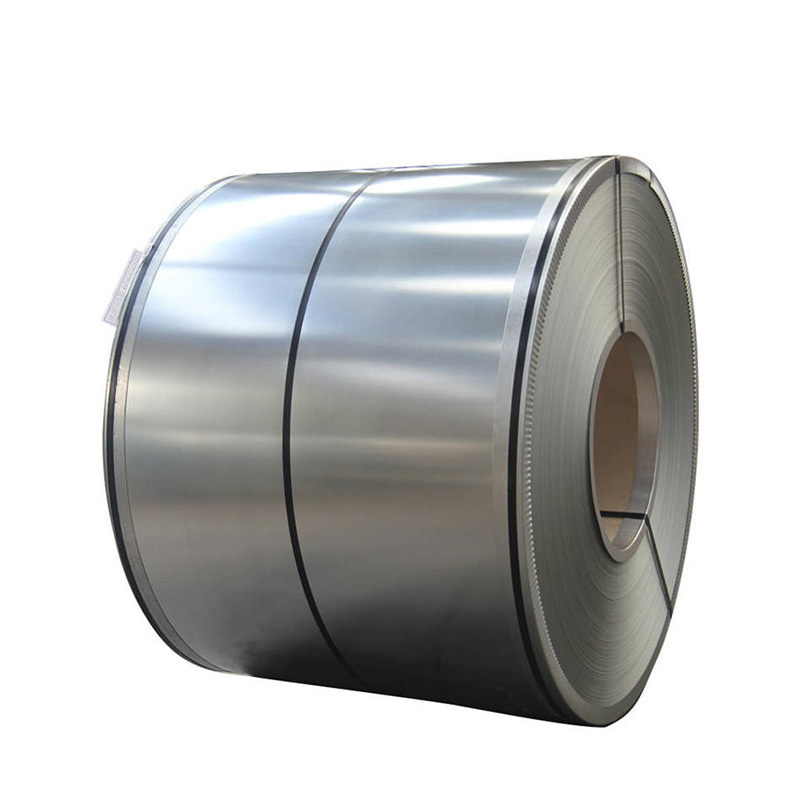

316L stainless steel, a grade renowned for its corrosion resistance and exceptional mechanical properties, is widely used in a range of industries. The cold-rolled coil is the result of meticulous processing, ensuring consistent quality and precise dimensions.

| Stainless Steel Coil | |

| Standard: | ASTM,GB,JIS,AISI,EN,DIN |

| Grade: | 201/304/316L/310S/254/2205/2507/904L, etc. |

| Width(mm): | 1000/1219/1500/1800/2000mm or Customized |

| Thickness(mm): | Cold Rolled: 0.15mm-3.0mm |

| Surface: | No.1,No.3,No.4,TR,HL,2D,2B,BA,8K |

| Packing: | Standard Export Pack or Customized |

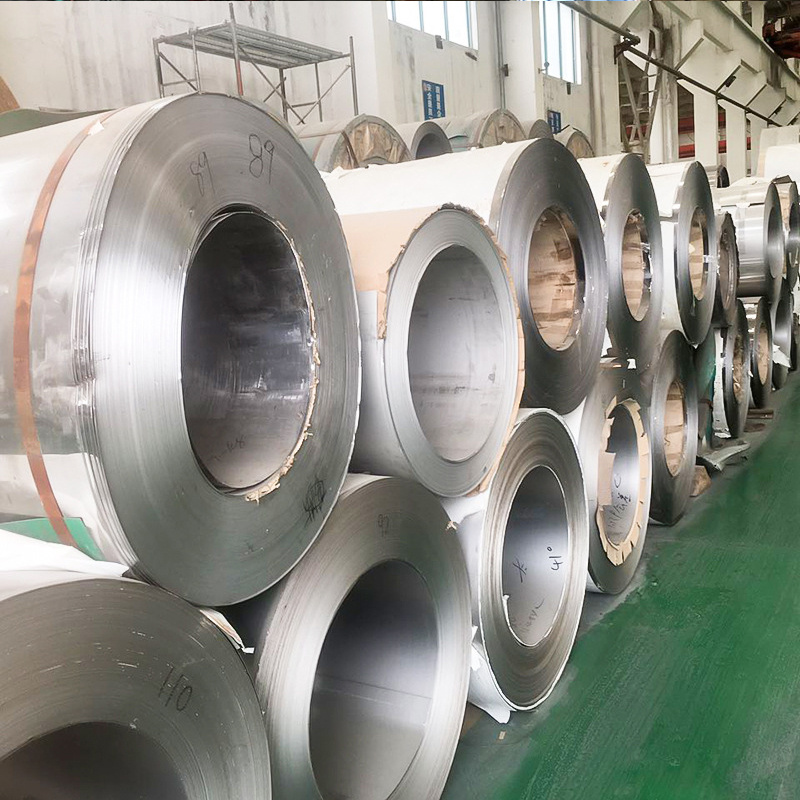

| Lead Time: | 7~14 days |

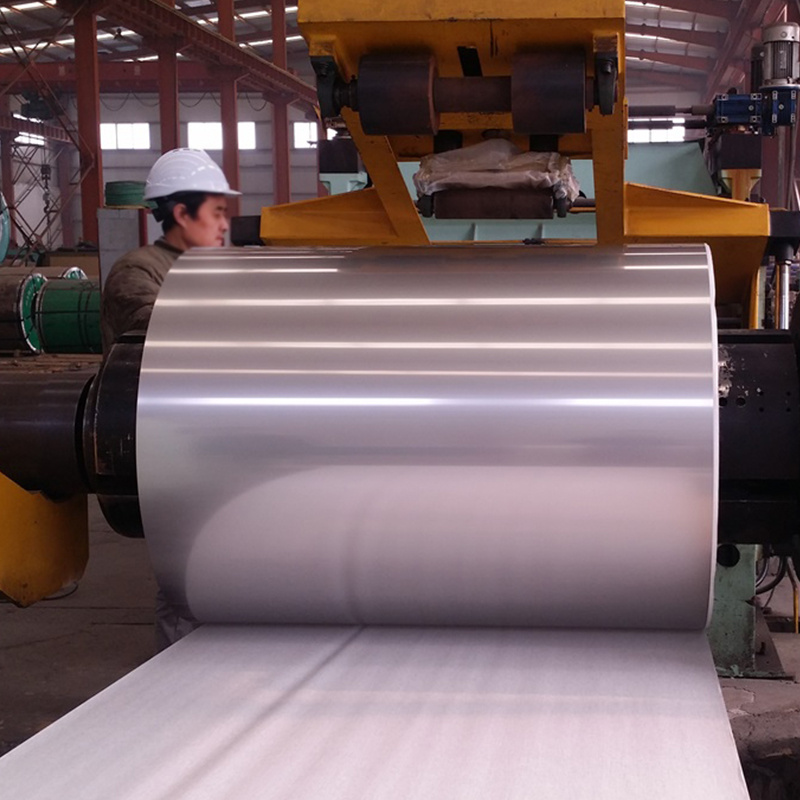

During the cold-rolling process, the steel is passed through rollers under immense pressure, reducing its thickness while maintaining its strength and ductility. This technique not only preserves the inherent properties of 316L stainless steel but also enhances its surface finish and overall appearance.

The 316L grade offers superior corrosion resistance due to its high chromium and nickel content, along with low carbon content. This combination imparts exceptional resistance to acids, alkalis, and most corrosive environments, making it an ideal choice for a range of applications.

In the production and manufacturing sectors, 316L stainless steel cold-rolled coil is utilized in the fabrication of components for chemical processing plants, oil and gas pipelines, medical equipment, and food processing equipment. Its non-reactive nature ensures purity in critical applications such as these.

Moreover, the sleek and shiny finish of the cold-rolled coil complements its versatility in the field of design and architecture, where it is often used for cladding exterior and interior surfaces, as well as in the production of furniture and consumer goods.

The cold-rolled coil's consistent quality and ease of installation make it a highly valued addition to various industries, ensuring durability and longevity in critical applications.