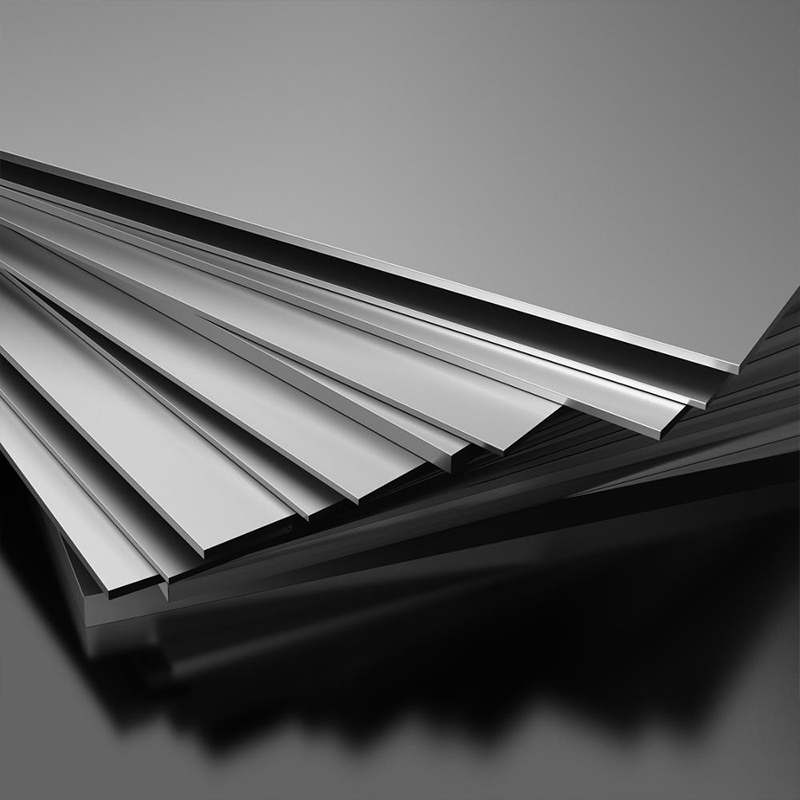

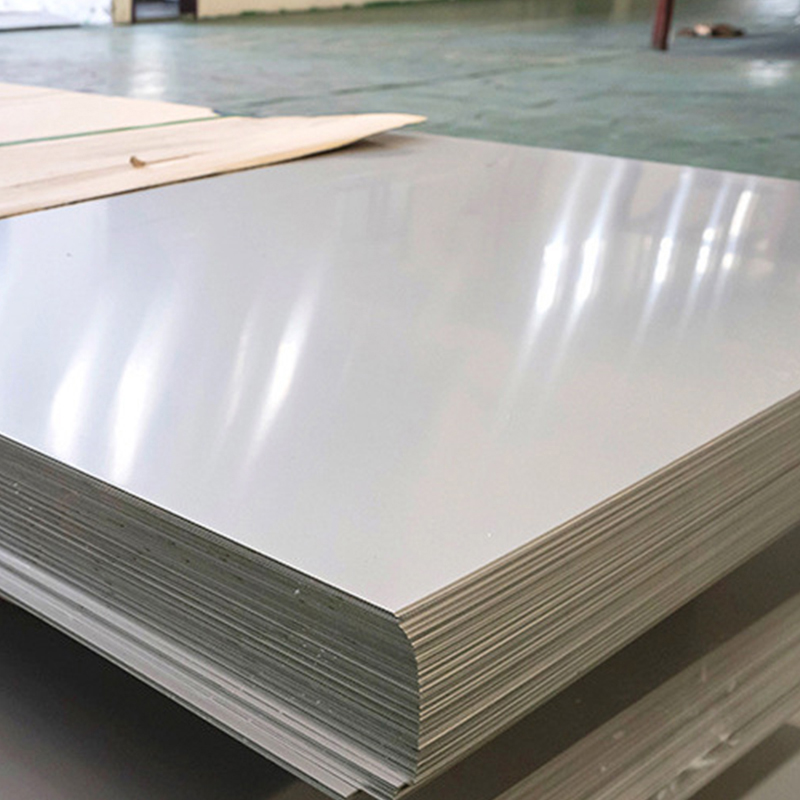

316L stainless steel cold rolled plate

316 and 316L stainless steel cold rolled plates are high-quality metal products widely used in various industries. They are both made from the 316-grade stainless steel, which offers excellent corrosion resistance, high strength, and heat resistance.

| Material | 316 316L Stainless Steel |

| Form | Cold Rolled Plate |

| Thickness | Varies (e.g., 0.5mm - 5mm) |

| Width | Varies (e.g., 1000mm - 1500mm) |

| Length | Varies (e.g., 2000mm - 6000mm) |

| Surface Finish | 2B (Bright, Cold Rolled) or BA (Bright Annealed) |

| Tensile Strength | Typically ≥ 515 MPa (75,000 psi) |

| Yield Strength | Typically ≥ 205 MPa (30,000 psi) |

| Elongation | Typically ≥ 40% |

| Hardness (Rockwell) | Typically ≤ 95 HRB |

| Corrosion Resistance | Excellent |

| Magnetic | No (Non-magnetic) |

| Applications | Marine environments, chemical processing, food and beverage industry, medical equipment, pharmaceutical industry, etc. |

| Chemical Composition | Carbon (C): 0.08% maximum Silicon (Si): 1.00% maximum Manganese (Mn): 2.00% maximum Phosphorus (P): 0.045% maximum Sulfur (S): 0.030% maximum Chromium (Cr): 16.00% - 18.00% Nickel (Ni): 10.00% - 14.00% Molybdenum (Mo): 2.00% - 3.00% Nitrogen (N): 0.10% maximum |

Here are some key features and advantages of 316 and 316L stainless steel cold rolled plates:

1.Corrosion resistance: Both 316 and 316L stainless steel cold rolled plates exhibit superior resistance to corrosion, making them suitable for use in aggressive environments. They can withstand exposure to chemicals, acids, chlorides, and other corrosive substances.

2.High strength: 316 and 316L stainless steel cold rolled plates have excellent mechanical properties, providing high tensile strength and good toughness. This makes them ideal for applications that require structural integrity and reliability.

3.Heat resistance: The plates can withstand high-temperature environments without experiencing significant deformation or loss of strength. They are suitable for use in elevated temperature applications such as heat exchangers, boilers, and exhaust systems.

4.Low carbon content (316L): 316L stainless steel cold rolled plate has a lower carbon content compared to 316, resulting in improved weldability and reduced susceptibility to sensitization. It is often preferred in applications where welding is required.

5.Versatility: 316 and 316L stainless steel cold rolled plates are highly versatile and find applications in various industries, including chemical processing, marine environments, pharmaceuticals, food processing, and medical equipment manufacturing.

It's important to note that while 316 and 316L stainless steel cold rolled plates offer exceptional performance in corrosive environments, they may come at a higher cost compared to other stainless steel grades. Therefore, it is crucial to evaluate specific requirements and consult with experts before selecting the appropriate stainless steel grade for a particular application.