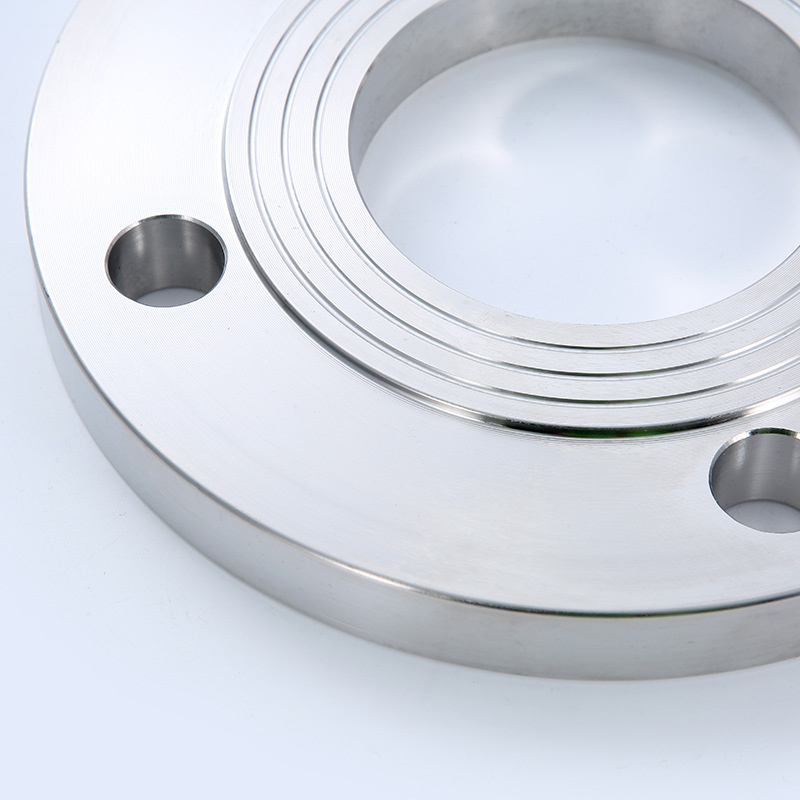

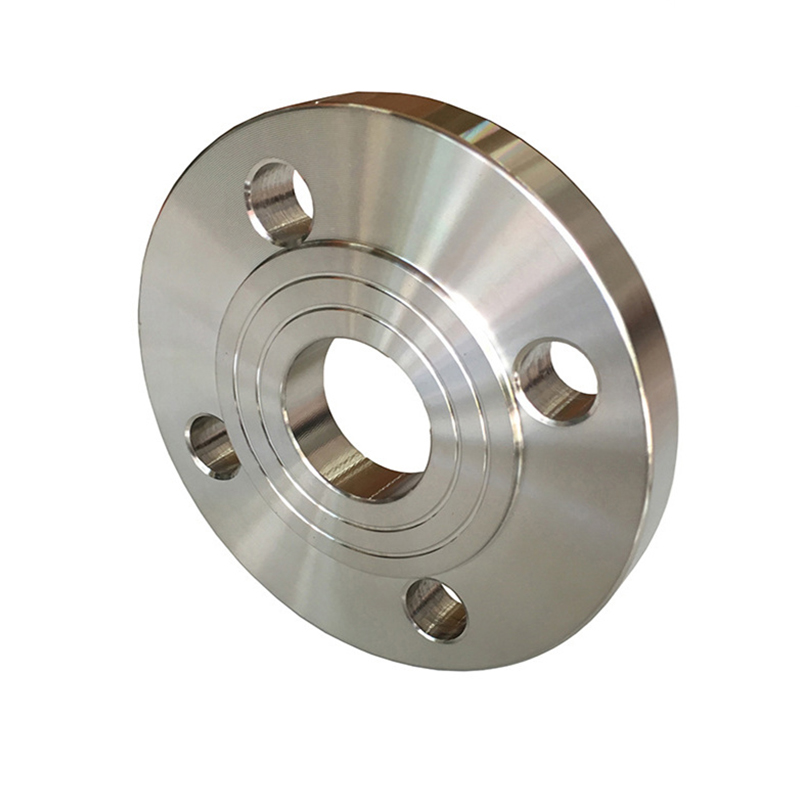

316L Stainless Steel Flange

The 316L stainless steel flange is a high-quality and corrosion-resistant pipe fitting widely used in industries that require superior performance in demanding environments. Here is an introduction to the product:

Material and Corrosion Resistance: The 316L stainless steel flange is made from premium-grade 316L stainless steel, which is an austenitic stainless steel with low carbon content. This alloy offers excellent corrosion resistance, making it highly resistant to corrosive substances such as acids, alkalis, and chloride-containing solutions. It is particularly suited for applications where exposure to harsh or corrosive environments is expected.

Types and Configurations: The 316L stainless steel flange is available in various types and configurations to meet diverse industry requirements. Common types include slip-on flanges, weld neck flanges, blind flanges, and lap joint flanges. These options provide flexibility in connecting pipes or valves, enabling efficient installation and maintenance.

Sizes and Specifications: The dimensions and specifications of the 316L stainless steel flange can be customized to fit different piping systems. It is available in a wide range of sizes, catering to small, medium, and large diameter pipes, ensuring compatibility with various industrial setups.

Connection Methods: The 316L stainless steel flange can be easily connected to pipes or valves using welding techniques such as TIG (tungsten inert gas) welding or MIG (metal inert gas) welding. Additionally, it can also be threaded onto pipes or joined using socket weld connections. These methods ensure strong and leak-free connections, guaranteeing the integrity of the overall system.

Applications: The 316L stainless steel flange finds extensive application in industries such as chemical processing, pharmaceuticals, oil and gas, marine, and food processing. Its outstanding corrosion resistance, high strength, and excellent mechanical properties make it suitable for critical applications involving high temperatures, high pressures, or corrosive substances. It is commonly used in pipelines, heat exchangers, pressure vessels, and other equipment where reliability and durability are paramount.

In summary, the 316L stainless steel flange is a premium-grade, corrosion-resistant pipe fitting widely used in demanding industrial applications. Its exceptional corrosion resistance, versatility in types and sizes, and ease of connection provide reliable and leak-free connections. It is extensively utilized in industries such as chemical processing, pharmaceuticals, oil and gas, marine, and food processing, where its superior performance in harsh environments is highly valued.

| 316L Stainless Steel Flange Chemical Compositions |

| Grade | C | Mn | P | S | Si | Cr | Ni | Mo | N |

| 316L | ≤0.03 | ≤2.0 | ≤0.045 | ≤0.03 | ≤0.75 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | ≤0.10 |

| Parameter | Description |

| Material | 316L stainless steel |

| Size Range | 1/2 inch - 36 inch |

| Pressure Class | 150 pounds, 300 pounds, 600 pounds |

| Flange Face Type | Raised face (RF), Flat face (FF), Ring type joint (RTJ) |

| Flange Standard | ANSI B16.5, ASME B16.47, DIN, EN, JIS |

| Temperature Range | -200°C to +800°C |

| Suitable Media | Water, Oil, Gas, Chemicals, etc. |

| Application Areas | Petrochemical industry, Pharmaceutical industry, Food processing, Marine applications, etc. |

| ANSI, ASME, ASA, B16.5 150lb/sq.in. WELDING NECK FLANGE RF | |||||||||||

| ø | D | b | g | m | a | J* | h | k | Holes | l | Kg. |

| 1/2" | 88,9 | 11,1 | 34,9 | 30,2 | 21,3 | 15,7 | 47,6 | 60,3 | 4 | 15,9 | 0,500 |

| 3/4" | 98,4 | 12,7 | 42,9 | 38,1 | 26,7 | 20,8 | 52,4 | 69,8 | 4 | 15,9 | 0,700 |

| 1" | 107,9 | 14,3 | 50,8 | 49,2 | 33,5 | 26,7 | 55,6 | 79,4 | 4 | 15,9 | 1,100 |

| 1 1/4" | 117,5 | 15,9 | 63,5 | 58,8 | 42,2 | 35,1 | 57,1 | 88,9 | 4 | 15,9 | 1,500 |

| 1 1/2" | 127,0 | 17,5 | 73,0 | 65,1 | 48,3 | 40,9 | 61,9 | 98,4 | 4 | 15,9 | 1,800 |

| 2" | 152,4 | 19,0 | 92,1 | 77,8 | 60,3 | 52,6 | 63,5 | 120,6 | 4 | 19,0 | 2,700 |

| 2 1/2" | 177,8 | 22,2 | 104,8 | 90,5 | 73,1 | 62,7 | 69,8 | 139,7 | 4 | 19,0 | 4,400 |

| 3" | 190,5 | 23,8 | 127,0 | 107,9 | 88,9 | 78,0 | 69,8 | 152,4 | 4 | 19,0 | 5,200 |

| 3 1/2" | 215,9 | 23,8 | 139,7 | 122,2 | 101,6 | 90,2 | 71,4 | 177,8 | 8 | 19,0 | 6,400 |

| 4" | 228,6 | 23,8 | 157,2 | 134,9 | 114,3 | 102,4 | 76,2 | 190,5 | 8 | 19,0 | 7,500 |

| 5" | 254,0 | 23,8 | 185,7 | 163,5 | 141,2 | 128,3 | 88,9 | 215,9 | 8 | 22,2 | 9,200 |

| 6" | 279,4 | 25,4 | 215,9 | 192,1 | 168,4 | 154,2 | 88,9 | 241,3 | 8 | 22,2 | 11,000 |

| 8" | 342,9 | 28,6 | 269,9 | 246,1 | 219,1 | 202,7 | 101,6 | 298,4 | 8 | 22,2 | 18,300 |

| 10" | 406,4 | 30,2 | 323,8 | 304,8 | 273,0 | 254,5 | 101,6 | 361,9 | 12 | 25,4 | 25,000 |

| 12" | 482,6 | 31,7 | 381,0 | 365,1 | 323,8 | 304,8 | 114,3 | 431,8 | 12 | 25,4 | 39,000 |

| 14" | 533,4 | 34,9 | 412,7 | 400,0 | 355,6 | 336,5 | 127,0 | 476,2 | 12 | 28,6 | 51,000 |

| 16" | 596,9 | 36,5 | 469,9 | 457,2 | 406,4 | 387,3 | 127,0 | 539,7 | 16 | 28,6 | 60,000 |

| 18" | 635,0 | 39,7 | 533,4 | 504,8 | 457,2 | 438,1 | 139,7 | 577,8 | 16 | 31,7 | 71,000 |

| 20" | 698,5 | 42,9 | 584,2 | 558,8 | 508,0 | 488,9 | 144,5 | 635,0 | 20 | 31,7 | 88,000 |

| 22" | 749,3 | 46,0 | 641,2 | 609,6 | 558,8 | 539,7 | 149,2 | 692,1 | 20 | 34,9 | 102,000 |

| 24" | 812,8 | 47,6 | 692,1 | 663,6 | 609,6 | 590,5 | 152,4 | 749,3 | 20 | 34,9 | 119,000 |

| *The data "J" corresponds to the STD schedule | |||||||||||

| ANSI, ASME, ASA B16.5 300lb/sq.in. WELDING NECK FLANGE RF | |||||||||||

| ø | D | b | g | m | a | J* | h | k | Holes | l | Kg. |

| 1/2" | 95,2 | 14,3 | 34,9 | 38,1 | 21,3 | 15,7 | 52,4 | 66,7 | 4 | 15,9 | 0,900 |

| 3/4" | 117,5 | 15,9 | 42,9 | 47,6 | 26,7 | 20,8 | 57,1 | 82,5 | 4 | 19,0 | 1,500 |

| 1" | 123,8 | 17,5 | 50,8 | 54,0 | 33,5 | 26,7 | 61,9 | 88,9 | 4 | 19,0 | 1,900 |

| 1 1/4" | 133,3 | 19,0 | 63,5 | 63,5 | 42,2 | 35,1 | 65,1 | 98,4 | 4 | 19,0 | 2,600 |

| 1 1/2" | 155,6 | 20,6 | 73,0 | 69,8 | 48,3 | 40,9 | 68,3 | 114,3 | 4 | 22,2 | 3,300 |

| 2" | 165,1 | 22,2 | 92,1 | 84,1 | 60,3 | 52,6 | 69,8 | 127,0 | 8 | 19,0 | 3,600 |

| 2 1/2" | 190,5 | 25,4 | 104,8 | 100,0 | 73,1 | 62,7 | 76,2 | 149,2 | 8 | 22,2 | 5,400 |

| 3" | 209,5 | 28,6 | 127,0 | 117,5 | 88,9 | 78,0 | 79,4 | 168,3 | 8 | 22,2 | 7,400 |

| 3 1/2" | 228,6 | 30,2 | 139,7 | 133,3 | 101,6 | 90,2 | 81,0 | 184,1 | 8 | 22,2 | 8,900 |

| 4" | 254,0 | 31,7 | 157,2 | 146,0 | 114,3 | 102,4 | 85,7 | 200,0 | 8 | 22,2 | 11,900 |

| 5" | 279,4 | 34,9 | 185,7 | 177,8 | 141,2 | 128,3 | 98,4 | 234,9 | 8 | 22,2 | 16,000 |

| 6" | 317,5 | 36,5 | 215,9 | 206,4 | 168,4 | 154,2 | 98,4 | 269,9 | 12 | 22,2 | 20,200 |

| 8" | 381,0 | 41,3 | 269,9 | 260,3 | 219,1 | 202,7 | 111,1 | 330,2 | 12 | 25,4 | 31,000 |

| 10" | 444,5 | 47,6 | 323,4 | 320,7 | 273,0 | 254,5 | 117,5 | 387,3 | 16 | 28,6 | 44,300 |

| 12" | 520,7 | 50,8 | 381,0 | 374,6 | 323,8 | 304,8 | 130,2 | 450,8 | 16 | 31,7 | 64,000 |

| 14" | 584,2 | 54,0 | 412,7 | 425,4 | 355,6 | 336,5 | 142,9 | 514,3 | 20 | 31,7 | 88,000 |

| 16" | 647,7 | 57,1 | 469,9 | 482,6 | 406,4 | 387,3 | 146,0 | 571,5 | 20 | 34,9 | 113,000 |

| 18" | 711,2 | 60,3 | 533,4 | 533,4 | 457,2 | 438,1 | 158,7 | 628,6 | 24 | 34,9 | 134,000 |

| 20" | 774,7 | 63,5 | 584,2 | 587,4 | 508,0 | 488,9 | 161,9 | 685,8 | 24 | 34,9 | 171,000 |

| 22" | 838,2 | 66,7 | 641,2 | 641,2 | 558,8 | 539,7 | 165,1 | 742,9 | 24 | 41,3 | 195,000 |

| 24" | 914,4 | 69,8 | 692,1 | 701,7 | 609,6 | 590,5 | 168,3 | 812,8 | 24 | 41,3 | 238,000 |

| *The data "J" corresponds to the STD schedule | |||||||||||

| ANSI/ASME/ASA B16.5 600lb/sq.in. WELDING NECK FLANGE RF | |||||||||||

| ø | D | b | g | m | a | J* | h | k | Holes | l | Kg. |

| 1/2" | 95,2 | 14,3 | 34,9 | 38,1 | 21,3 | 15,7 | 52,4 | 66,7 | 4 | 15,9 | 0,900 |

| 3/4" | 117,5 | 15,9 | 42,9 | 47,6 | 26,7 | 20,9 | 57,1 | 82,5 | 4 | 19,0 | 1,500 |

| 1" | 123,8 | 17,5 | 50,8 | 54,0 | 33,5 | 26,7 | 61,9 | 88,9 | 4 | 19,0 | 1,900 |

| 1 1/4" | 133,3 | 20,6 | 63,5 | 63,5 | 42,2 | 35,0 | 66,7 | 98,4 | 4 | 19,0 | 2,600 |

| 1 1/2" | 155,6 | 22,2 | 73,0 | 69,8 | 48,3 | 40,9 | 69,8 | 114,3 | 4 | 22,2 | 3,300 |

| 2" | 165,1 | 25,4 | 92,1 | 84,1 | 60,3 | 52,6 | 73,0 | 127,0 | 8 | 19,0 | 4,700 |

| 2 1/2" | 190,5 | 28,6 | 104,8 | 100,0 | 73,1 | 62,7 | 79,4 | 149,2 | 8 | 22,2 | 6,500 |

| 3" | 209,5 | 31,7 | 127,0 | 117,5 | 88,9 | 78,0 | 82,5 | 168,3 | 8 | 22,2 | 8,700 |

| 3 1/2" | 228,6 | 34,9 | 139,7 | 133,3 | 101,6 | 90,1 | 85,7 | 184,1 | 8 | 25,4 | 11,200 |

| 4" | 273,0 | 38,1 | 157,2 | 152,4 | 114,3 | 102,4 | 101,6 | 215,9 | 8 | 25,4 | 18,100 |

| 5" | 330,2 | 44,4 | 185,7 | 188,9 | 141,2 | 128,2 | 114,3 | 266,7 | 8 | 28,6 | 30,500 |

| 6" | 355,6 | 47,6 | 215,9 | 222,2 | 168,4 | 154,2 | 117,5 | 292,1 | 12 | 28,6 | 36,200 |

| 8" | 419,1 | 55,6 | 269,9 | 273,0 | 219,1 | 202,7 | 133,3 | 349,2 | 12 | 31,7 | 56,500 |

| 10" | 508,0 | 63,5 | 323,8 | 342,9 | 273,0 | 254,5 | 152,4 | 431,8 | 16 | 34,9 | 91,000 |

| 12" | 558,8 | 66,7 | 381,0 | 400,0 | 323,8 | 304,8 | 155,6 | 488,9 | 20 | 34,9 | 105,000 |

| 14" | 603,2 | 69,8 | 412,7 | 431,8 | 355,6 | * | 165,1 | 527,0 | 20 | 38,1 | 125,000 |

| 16" | 685,8 | 76,2 | 469,9 | 495,3 | 406,4 | 177,8 | 603,2 | 20 | 41,3 | 178,000 | |

| 18" | 742,9 | 82,5 | 533,4 | 546,1 | 457,2 | 184,1 | 654,0 | 20 | 44,4 | 261,000 | |

| 20" | 812,8 | 88,9 | 584,2 | 609,6 | 508,0 | 190,5 | 723,9 | 24 | 44,4 | 268,000 | |

| 22" | 869,9 | 95,2 | 641,2 | 666,7 | 558,8 | 196,8 | 777,9 | 24 | 47,6 | 328,000 | |

| 24" | 939,8 | 101,6 | 692,1 | 717,5 | 609,6 | 203,2 | 838,2 | 24 | 50,8 | 380,000 | |

| *The data "J" corresponds to the STD schedule | |||||||||||

| To be specifiedby customer | |||||||||||