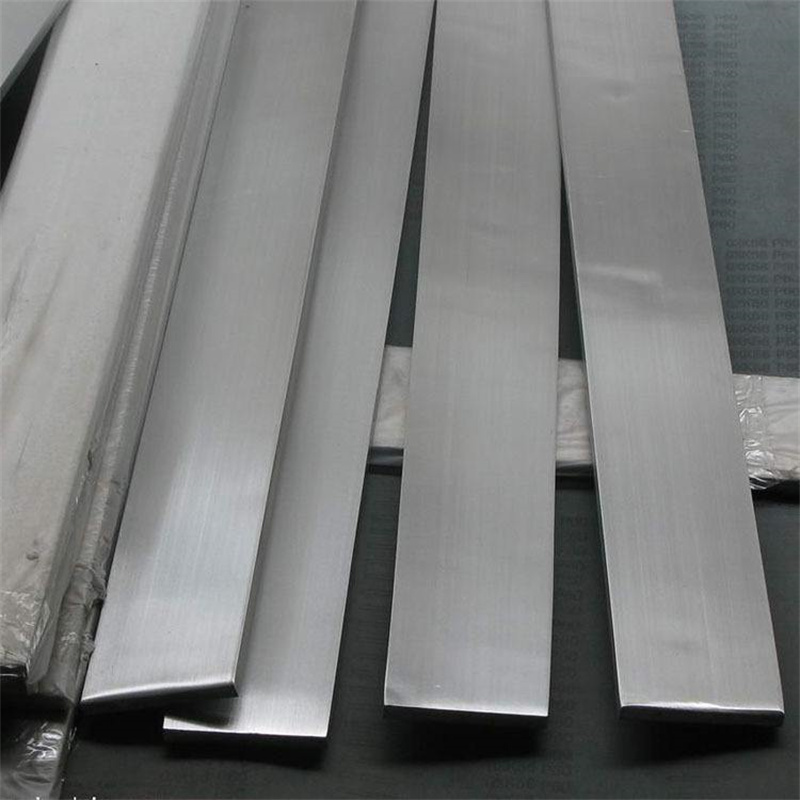

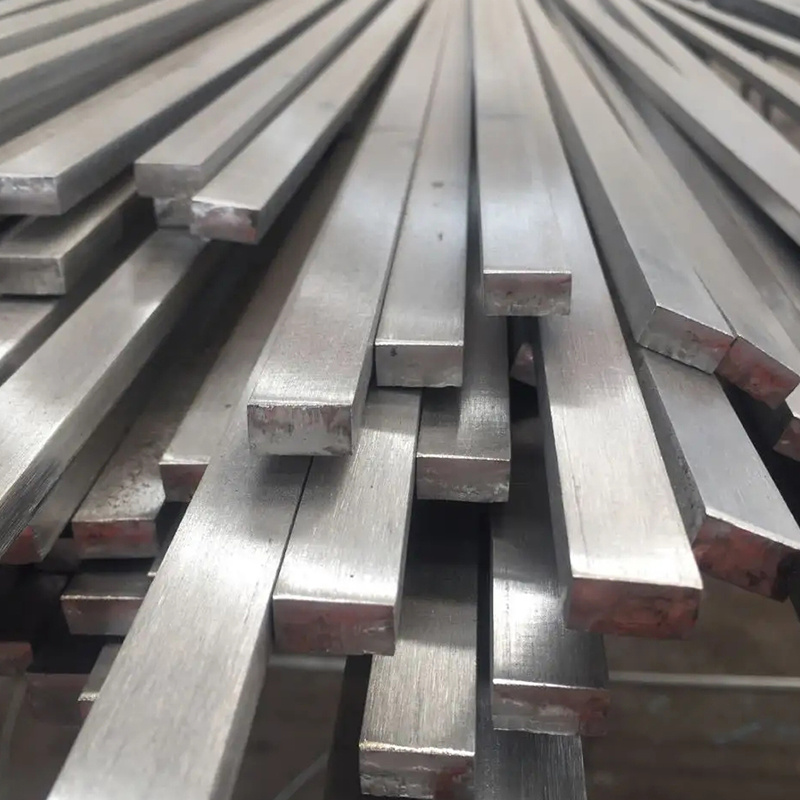

316L stainless steel flat steel

316L stainless steel flat bar is a high-quality stainless steel product, widely used in various industries due to its excellent corrosion resistance, high strength, and good processing performance.

Our 316L stainless steel flat bar is a high-quality product that offers excellent corrosion resistance, high strength, and good processing performance. It is suitable for use in various industries that require corrosion resistance and long service life. We have implemented strict quality control throughout the production process to ensure the quality of our products. We provide various packaging options and ensure safe delivery within the agreed timeframe. Contact us today for more information about our 316L stainless steel flat bar products.

316L stainless steel flat bar is made of 316L stainless steel, which contains a small amount of Mo and is characterized by good corrosion resistance in acid and alkali environments. In addition, it has good weldability, formability, and fatigue resistance. The product has a low carbon content and is easy to process. It is suitable for use in corrosive environments, such as chemical plants, pulp and paper mills, food processing facilities, and other industries that require high corrosion resistance.

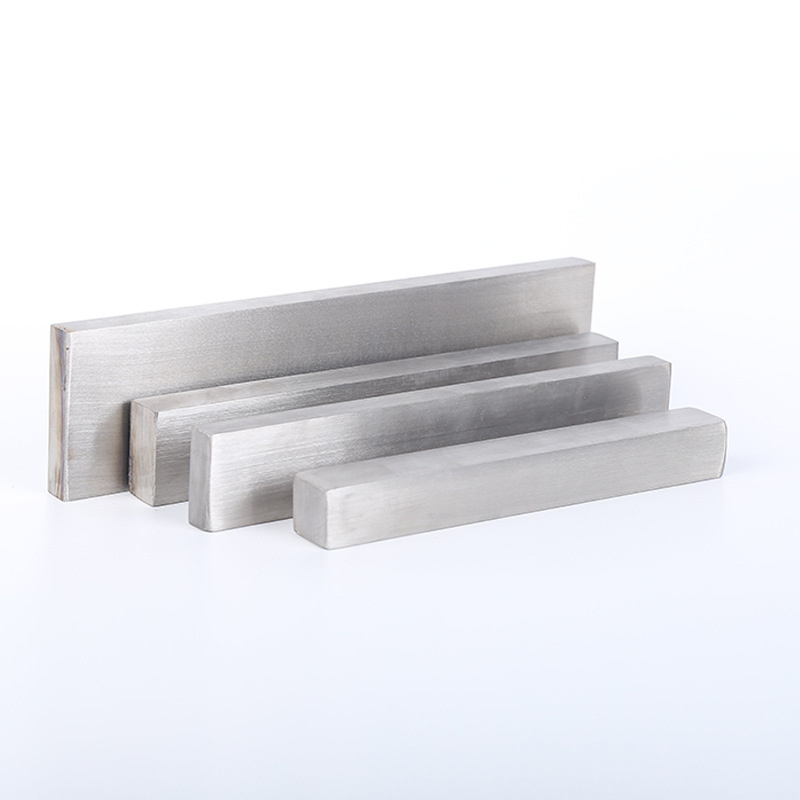

316L stainless steel flat bar can be used in a variety of applications, including structural members, piping, pressure vessels, chemical equipment, and other equipment that require corrosion resistance and long service life. It is also widely used in the automotive industry, aerospace industry, shipbuilding industry, and other fields that require high-performance materials.

In conclusion, the 304 stainless steel flat bar offers a combination of exceptional mechanical properties, corrosion resistance, and durability, making it an excellent choice for a wide range of industrial applications. Its adaptability to various fabrication processes and ease of cleaning further enhance its versatility and widespread use in various industries.

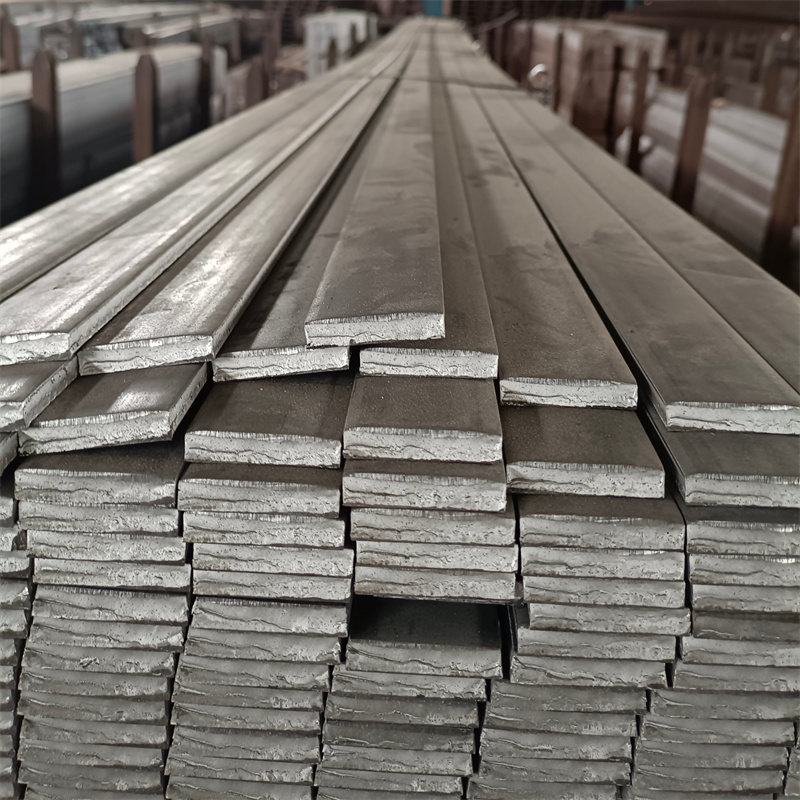

The production of 316L stainless steel flat bar requires a series of processes, including melting, casting, rolling, heat treatment, and surface treatment. The melting process uses high-purity raw materials to ensure the chemical composition and mechanical properties of the product. The casting process uses advanced casting technology to ensure the shape and size accuracy of the product. The rolling process uses precision rolling equipment to achieve the desired thickness and width of the product. The heat treatment process controls the temperature and time to achieve the desired microstructure and properties of the product. The surface treatment process improves the corrosion resistance and appearance of the product.

We have implemented strict quality control throughout the production process to ensure the quality of our 316L stainless steel flat bar. We use advanced testing equipment to test the chemical composition, mechanical properties, and surface quality of the product to ensure that it meets our stringent quality standards. In addition, we also conduct regular inspections to ensure that the product meets customer requirements.

Our 316L stainless steel flat bar is packaged in strong wooden boxes or steel drums for protection during transportation. We also provide customers with loading plans to ensure that the product is safely loaded onto the transportation means selected by the customer. We deliver the product within the agreed timeframe and keep customers informed of delivery status throughout the process.

| Product Name | 316L Stainless Steel Flat Bar |

| Composition | Carbon (C): ≤0.03% Manganese (Mn): ≤2.00% Phosphorus (P): ≤0.045% Sulfur (S): ≤0.03% Silicon (Si): ≤1.00% Chromium (Cr): 10.00-14.00% Nickel (Ni): 4.00-6.00% Molybdenum (Mo): 2.00-3.00% Titanium (Ti): ≤0.75% Aluminum (Al): ≤0.75% Copper (Cu): ≤0.75% Iron (Fe): Balance |