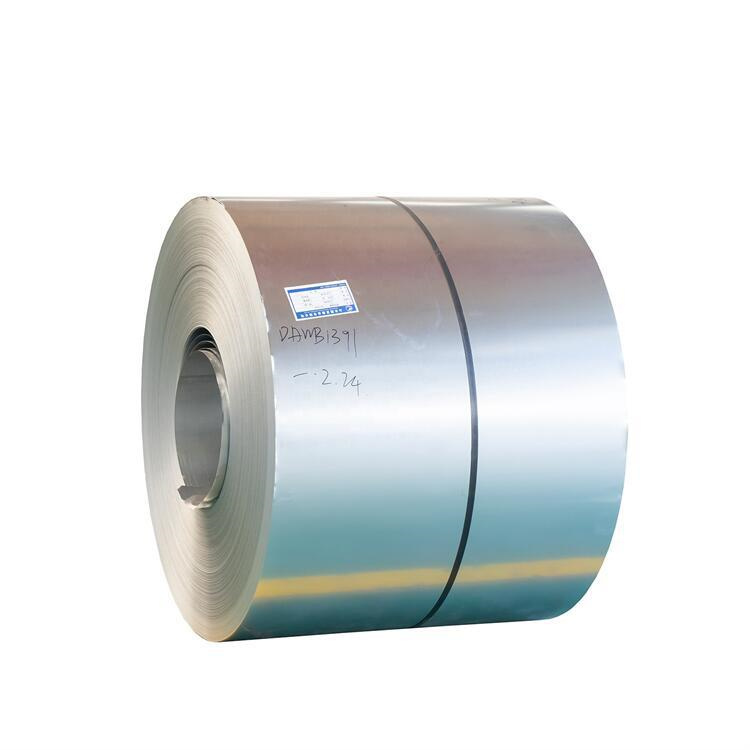

316L Stainless Steel Hot-Rolled Coils

316L stainless steel, a member of the austenitic stainless steel family, is a highly corrosion-resistant material, making it an excellent choice for a variety of applications. This grade of stainless steel, containing a low carbon content, is known for its exceptional strength and formability.

| Stainless Steel Coil | |

| Standard: | ASTM,GB,JIS,AISI,EN,DIN |

| Grade: | 201/304/316L/310S/254/2205/2507/904L, etc. |

| Width(mm): | 1000/1219/1500/1800/2000mm or Customized |

| Thickness(mm): | Hot Rolled: 3.0mm-10.0mm or Customized |

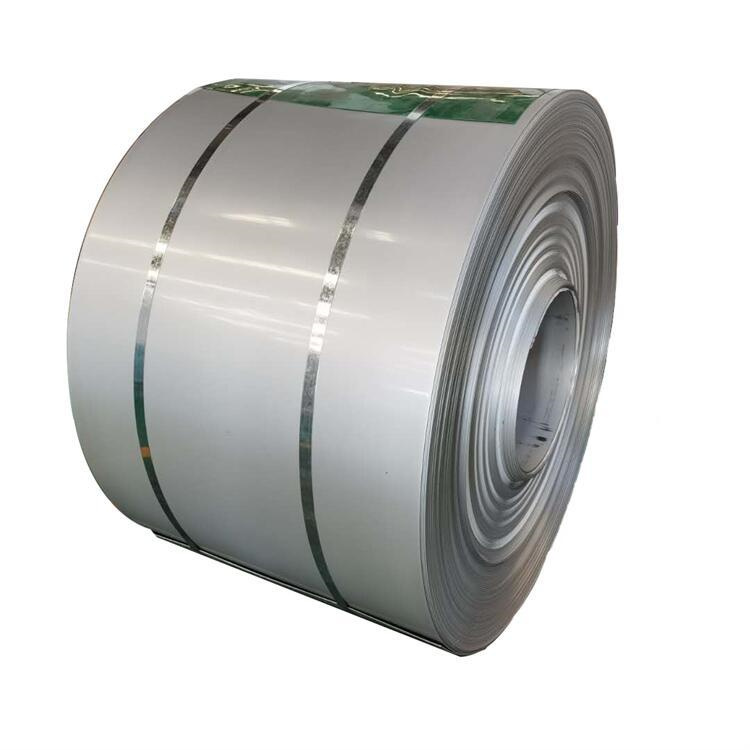

| Surface: | No.1,No.3,No.4,TR,HL,2D,2B,BA,8K |

| Packing: | Standard Export Pack or Customized |

| Lead Time: | 7~14 days |

The production of hot-rolled coils begins with the melting of high-grade 316L stainless steel. The molten metal is then poured into ingots or continuous casting machines. Following this, the material undergoes hot rolling, where it is heated and passed through rollers to achieve the desired thickness and shape. The hot-rolled coil is then cooled, either air or water-cooled, depending on the specifics of the application.

316L stainless steel offers excellent resistance to both corrosion and heat, making it suitable for a range of applications. It is commonly used in the manufacturing of utensils and components that require high resistance to corrosion and wear, such as in chemical processing, food processing, and medical equipment. Additionally, 316L stainless steel is often employed in the construction industry due to its exceptional durability and aesthetics.

The demand for 316L stainless steel hot-rolled coil is expected to continue growing as industries become more aware of the benefits of using corrosion-resistant materials. The properties of 316L stainless steel, coupled with advancements in production methods, are set to further expand its range of applications in the coming years.