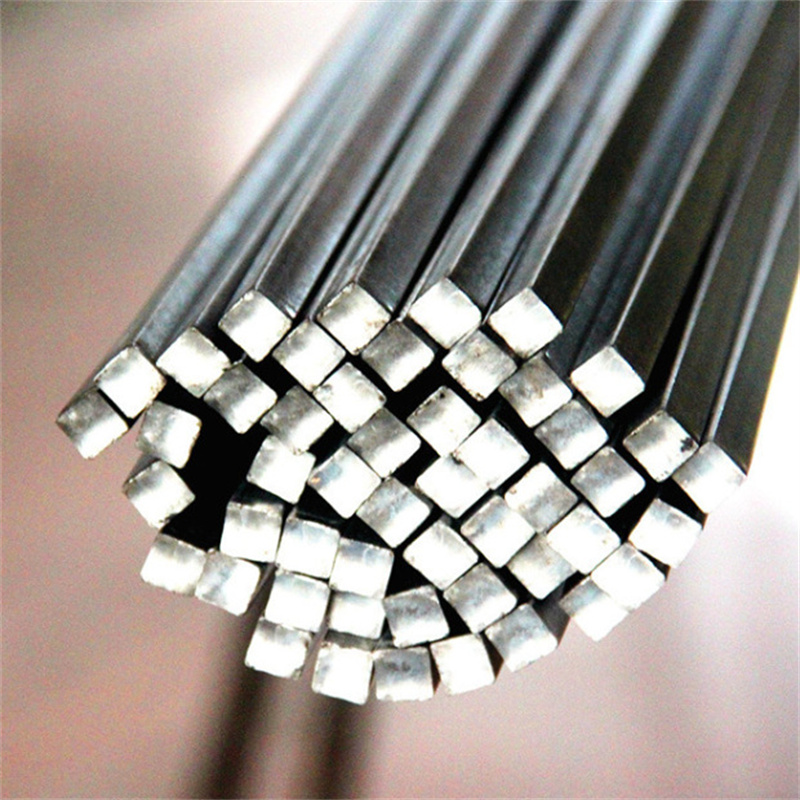

316L stainless steel square steel

The 316L stainless steel square steel bar is a high-quality material, widely used in various industries due to its excellent corrosion resistance, tensile strength, and durability. Manufactured using a precision process, this steel bar offers exceptional formability, making it suitable for a range of applications.

1.Corrosion Resistance: The 316L stainless steel has a chromium content that provides exceptional resistance to corrosion, making it suitable for use in harsh environments.

2.Tensile Strength: This grade of steel offers excellent tensile strength, ensuring durability and longevity in demanding applications.

3.Ductility: The 316L stainless steel square steel bar exhibits excellent ductility, allowing for greater flexibility in metal forming and processing.

4.Heat Resistance: The steel's heat resistance ensures stable performance at high temperatures, making it suitable for various industrial processes that require elevated temperatures.

5.Weldability: The 316L grade is highly weldable, facilitating easy assembly and repair of components made from this material.

1.Construction: Used in the construction industry for applications that require corrosion resistance, such as building frameworks, structural supports, and architectural components.

2.Automotive: Used in the automotive industry for components that require high tensile strength and corrosion resistance, such as body panels, chassis components, and exhaust systems.

3.Chemical Processing: Ideal for use in chemical processing equipment, piping systems, and storage tanks where resistance to corrosion is essential.

4.Marine Applications: Excellent choice for use in marine environments, offering long-term corrosion resistance and durability in saltwater conditions.

5.Food Processing: Suitable for use in food processing equipment due to its hygienic properties and ability to withstand rigorous cleaning and sanitation procedures.

6.Petroleum and Oil Refining: Used in the petroleum and oil refining industries for pipelines, valves, and other components that require resistance to acids and other corrosive substances.

7.Heat Exchangers: Ideal for use in heat exchangers due to its heat resistance and corrosion resistance properties, ensuring efficient heat transfer and longevity.

8.Electrical Industry: Used in electrical components and wiring due to its electrical conductivity and corrosion resistance properties.

9.Machinery and Equipment: In machinery and equipment manufacturing, the 316L stainless steel square steel bar is employed in components that require high durability and corrosion resistance, such as gears, shafts, bearings, and other precision parts.

10.Medical Equipment: Suitable for use in medical equipment due to its hygienic properties and ability to withstand rigorous cleaning and sterilization procedures.

In conclusion, the 316L stainless steel square steel bar offers a combination of exceptional corrosion resistance, tensile strength, ductility, and heat resistance, making it an excellent choice for a wide range of industrial applications. Its adaptability and reliability ensure longevity and performance in various demanding environments, making it a trusted material for critical applications across multiple industries.

| Material | 316L Stainless Steel |

| Chemical composition | Carbon (C): ≤0.030% Manganese (Mn): ≤2.00% Silicon (Si): ≤0.75% Phosphorus (P): ≤0.045% Sulfur (S): ≤0.030% Chromium (Cr): 10.00-14.00% Nickel (Ni): 10.00-14.00% Molybdenum (Mo): 2.00-3.00% Titanium (Ti): ≤0.75% Aluminum (Al): ≤0.25% Other Elements: ≤0.15% |

| Mechanical Properties | Yield Strength: ≥210 ksi Tensile Strength: ≥480 ksi Elongation: ≥35% Impact Strength: ≥12 ft-lb Hardness: ≤210 BHN |

| Physical Properties | Thermal Conductivity: ≤16.3 W/m·K at 25°C Thermal Expansion: ≤10.5 μm/m·K at 25°C Specific Heat: ≤460 J/kg·K at 25°C Modulus of Elasticity: ≤200 GPa at 25°C Poisson's Ratio: ≤0.32 at 25°C Density: 8.0 g/cm³ at 25°C |

| Corrosion Resistance Properties | Pitting Resistance: ≥650 hours in 3.5% NaCl at 75°C Sulfide Formation Resistance: ≥12 hours in H2S at 98°C and pH 3.8-4.2 Crevice Corrosion Resistance: ≥48 hours in 3.5% NaCl at 75°C and pH 6.5-7.5 Stress Corrosion Resistance: ≥48 hours in 3.5% NaCl at 75°C and pH 6.5-7.5 |