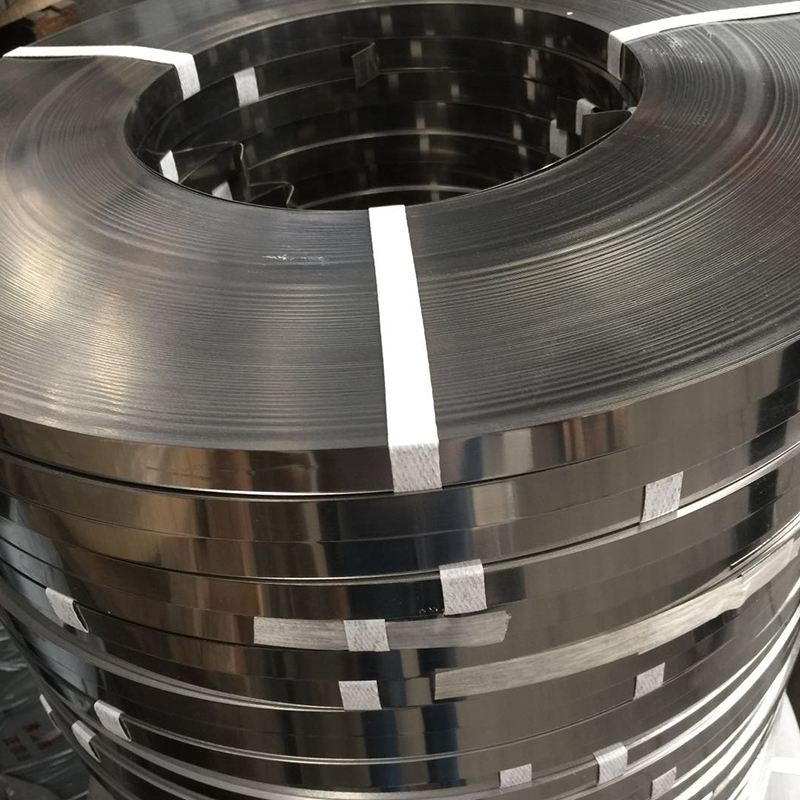

316L Stainless Steel Strip Coils

316L Stainless Steel Strip Coils, also known as 316L austenitic stainless steel strip, is a highly corrosion-resistant material that is widely used in various industries. It offers excellent mechanical properties and is commonly used in the production of steel strips, sheets, and other components.

| Stainless Steel Strip Coil | |

| Standard: | ASTM,GB,JIS,AISI,EN,DIN |

| Grade: | 201/304/316L/310S/254/2205/2507/904L, etc. |

| Width(mm): | Min. 10.0mm |

| Thickness(mm): | 0.15mm-10.0mm or Customized |

| Surface: | No.1,No.3,No.4,TR,HL,2D,2B,BA,8K |

| Packing: | Standard Export Pack or Customized |

| Lead Time: | 7~14 days |

The production of 316L stainless steel strip involves several steps. The initial step is the preparation of the molten alloy, which consists of various elements such as iron, chromium, nickel, and molybdenum. The molten alloy is then cast into ingots or billets.

The next step is hot rolling, where the ingots or billets are heated and rolled into thinner sheets or strips. After that, the strips go through a series of cold rolling and annealing processes to achieve the desired thickness and properties. Finally, the strips are cut to the desired length and wound into coils for easy handling and transportation.

316L stainless steel strip offers a combination of excellent mechanical properties, corrosion resistance, and durability. It has good tensile strength, yield strength, and ductility, making it suitable for a wide range of applications. Additionally, it has excellent resistance to corrosion and oxidation, making it suitable for use in harsh environments.

The main applications of 316L stainless steel strip include:

- Automotive industry: Used in the production of exhaust systems, fuel systems, and other components that require high corrosion resistance.

- Construction industry: Used in the production of roofing, cladding, and other building components that require durability and resistance to corrosion.

Manufacturing industry: Used in the production of machine parts, tools, and other components that require high strength and corrosion resistance.