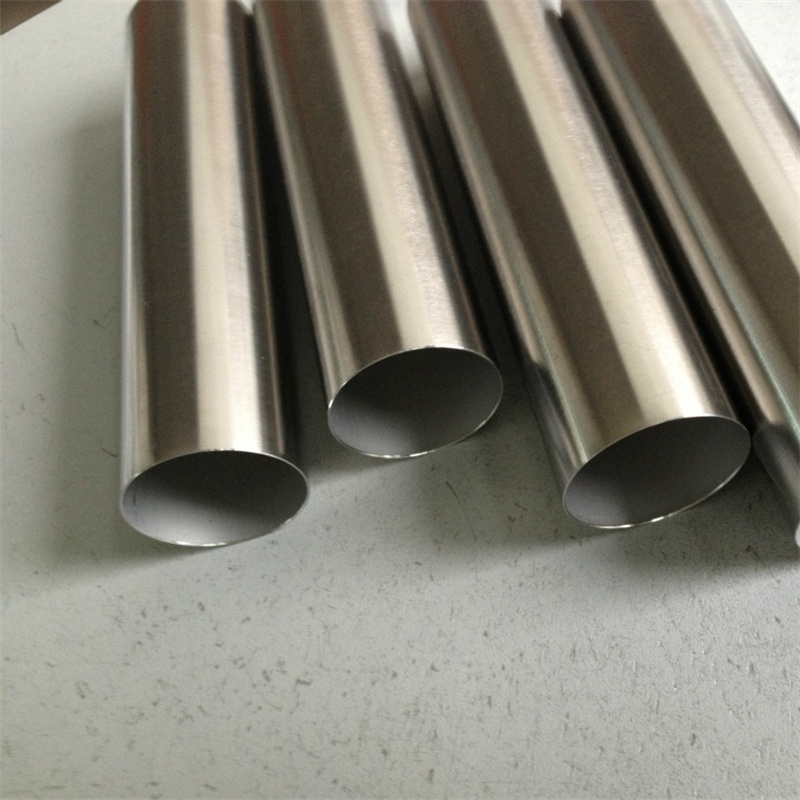

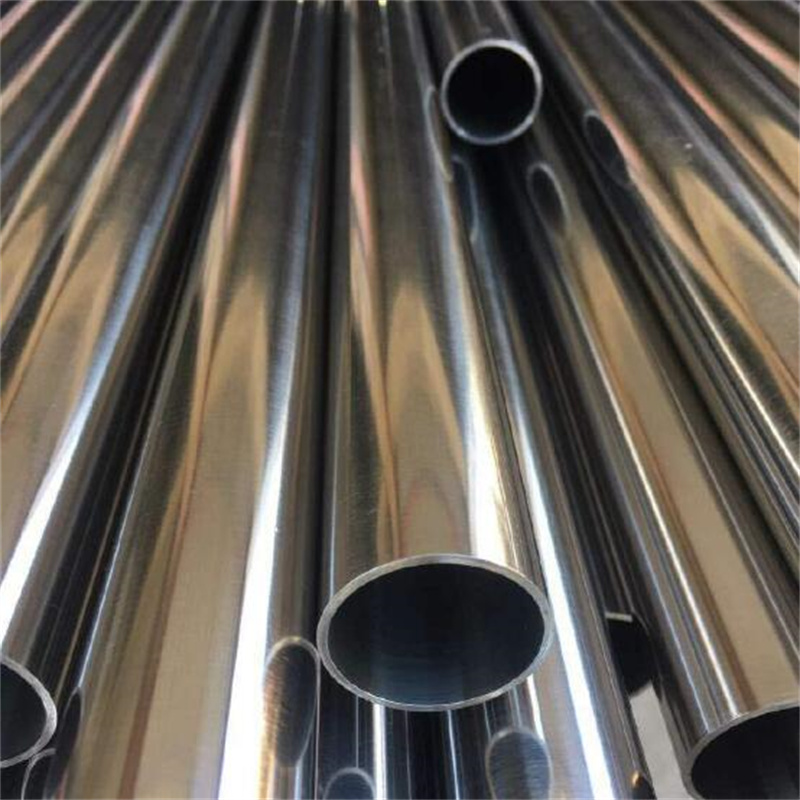

904L Precision Tube

The 904L precision tube is a high-quality stainless steel tube that is specifically designed for precision applications. It is made from an advanced grade of stainless steel known as 904L, which offers excellent corrosion resistance and durability.

With its excellent corrosion resistance, high strength, and heat resistance, the 904L precision tube is a versatile and durable solution for various precision applications. Its wide range of applications across industries attests to its reliability and performance.

Corrosion Resistance: The 904L precision tube exhibits exceptional resistance to various corrosive environments, including sulfuric acid, acetic acid, and other aggressive chemicals. This makes it suitable for applications in industries such as chemical processing, petrochemicals, and marine environments.

High Strength: The 904L stainless steel material used in the tube provides good mechanical properties, ensuring high strength and structural integrity.

Heat Resistance: The tube can withstand elevated temperatures without compromising its performance, making it suitable for applications involving heat transfer or exposure to high temperatures.

Low Carbon Content: The low carbon content of the material minimizes the risk of carbide precipitation during welding, improving its weldability and reducing the possibility of intergranular corrosion.

The 904L precision tube finds extensive usage in various industries due to its exceptional properties. Some common applications include:

Chemical Processing: It is widely used in equipment such as reactors, heat exchangers, and storage tanks due to its corrosion resistance against aggressive chemicals.

Oil and Gas Industry: The tube is utilized in offshore platforms, gas plants, and pipelines where resistance to chloride stress corrosion cracking is crucial.

Desalination Plants: Its corrosion resistance makes it ideal for desalination plants, where the tube is employed in heat exchangers and other critical components.

Marine Applications: Due to its resistance to saltwater and harsh marine environments, the 904L precision tube is commonly used in shipbuilding, offshore structures, and seawater handling systems.

Medical Equipment: The tube's high purity and corrosion resistance make it suitable for medical applications such as surgical instruments, implants, and biomedical devices.

The 904L precision tube finds extensive usage in various industries due to its exceptional properties. Some common applications include:

Chemical Processing: It is widely used in equipment such as reactors, heat exchangers, and storage tanks due to its corrosion resistance against aggressive chemicals.

Oil and Gas Industry: The tube is utilized in offshore platforms, gas plants, and pipelines where resistance to chloride stress corrosion cracking is crucial.

Desalination Plants: Its corrosion resistance makes it ideal for desalination plants, where the tube is employed in heat exchangers and other critical components.

Marine Applications: Due to its resistance to saltwater and harsh marine environments, the 904L precision tube is commonly used in shipbuilding, offshore structures, and seawater handling systems.

Medical Equipment: The tube's high purity and corrosion resistance make it suitable for medical applications such as surgical instruments, implants, and biomedical devices.

Our 904L precision tubes adhere to the highest quality standards and specifications. They are manufactured using advanced production techniques, ensuring dimensional accuracy, smooth surface finish, and reliable performance.

| Material | 904L stainless steel |

| Outer Diameter | Minimum: [Specify the minimum outer diameter in desired unit] Maximum: [Specify the maximum outer diameter in desired unit] |

| Wall Thickness Range | Minimum: [Specify the minimum wall thickness in desired unit] Maximum: [Specify the maximum wall thickness in desired unit] |

| Length | Standard Length: [Specify the standard length in desired unit] Customizable Length: [Specify if custom lengths are available and provide details, if applicable] Tolerance: [Specify the tolerance for dimensional measurements] Surface Finish: [Specify the surface finish options, such as polished, brushed, or others] |

| Corrosion Resistance | Chemical Resistance: Excellent resistance to sulfuric acid, acetic acid, and other corrosive chemicals. Chloride Stress Corrosion Cracking (CSCC) resistance: High resistance to CSCC in chloride-containing environments. |

| Mechanical Properties | Yield Strength: [Specify the yield strength in desired unit] Tensile Strength: [Specify the tensile strength in desired unit] Elongation: [Specify the elongation percentage] Heat Resistance: Can withstand elevated temperatures up to [Specify the temperature in desired unit] |

| Weldability | Good weldability due to low carbon content, minimizing carbide precipitation and intergranular corrosion risks. |

| Certification | [Specify any relevant certifications or standards that the product complies with] |

| Note | The specific values for dimensions, tolerances, strength, and other parameters may vary depending on the manufacturer and customer requirements. Please contact the supplier or manufacturer for detailed and precise product specifications. |

304 stainless steel hot rolled plate is a widely used and versatile metal product. It belongs to the austenitic stainless steel family, known for its excellent corrosion resistance, high temperature strength, and aesthetic appeal. This grade offers exceptional performance in various industries and applications.

| Grade | 304 |

| Manufacturing Method | Hot Rolled |

| Thickness Range | 3mm - 100mm |

| Width Range | Up to 2000mm |

| Length Range | Up to 6000mm |

| Surface Finish | No.1, 2B, BA, No.4, No.8, HL, etc. |

| Tensile Strength | ≥ 515 MPa |

| Yield Strength | ≥ 205 MPa |

| Elongation | ≥ 40% |

| Hardness (HB) | ≤ 201 (Brinell Hardness) |

| Density | 7.93 g/cm³ |

| Application | Carbon (C): ≤ 0.08% Silicon (Si): ≤ 1.00% Manganese (Mn): ≤ 2.00% Phosphorus (P): ≤ 0.045% Sulfur (S): ≤ 0.030% Chromium (Cr): 18.00 - 20.00% Nickel (Ni): 8.00 - 10.50% Silicon (Si): ≤ 1.00% |

Key features and advantages of 304 stainless steel hot rolled plate are as follows:

1.Excellent corrosion resistance: The plate exhibits excellent resistance to corrosion in a wide range of environments, including acidic, alkaline, and chloride-containing solutions. It withstands oxidation at high temperatures and resists pitting and crevice corrosion. This makes it suitable for applications in chemical processing, food industry, marine environments, and architectural structures.

2.High-temperature strength: 304 stainless steel hot rolled plate retains its mechanical properties at elevated temperatures, making it suitable for high-temperature applications. It has good heat resistance and can withstand thermal cycling without significant deformation or loss of strength. This property makes it ideal for use in heat exchangers, boilers, and furnace components.

3.Superior formability: The plate possesses excellent formability, allowing it to be easily shaped, bent, and fabricated into complex structures. It can be readily welded, machined, and formed using conventional techniques, enabling versatility in manufacturing processes.

4.Aesthetic appeal: 304 stainless steel hot rolled plate has a bright and reflective surface finish, providing an aesthetically pleasing appearance. Its smooth and polished surface makes it popular for decorative applications in architecture, interior design, and kitchen equipment.

5.Wide range of applications: The plate finds extensive use in various industries, including automotive, aerospace, pharmaceuticals, and construction. It is commonly employed in manufacturing equipment, appliances, utensils, sanitary fittings, and structural components that require a combination of corrosion resistance, strength, and aesthetics.

304 stainless steel hot rolled plate is a reliable and widely adopted material due to its excellent corrosion resistance, high-temperature strength, and versatility. When selecting 304 stainless steel hot rolled plate, it is essential to consider specific project requirements and consult with experts to ensure optimal performance for your application.