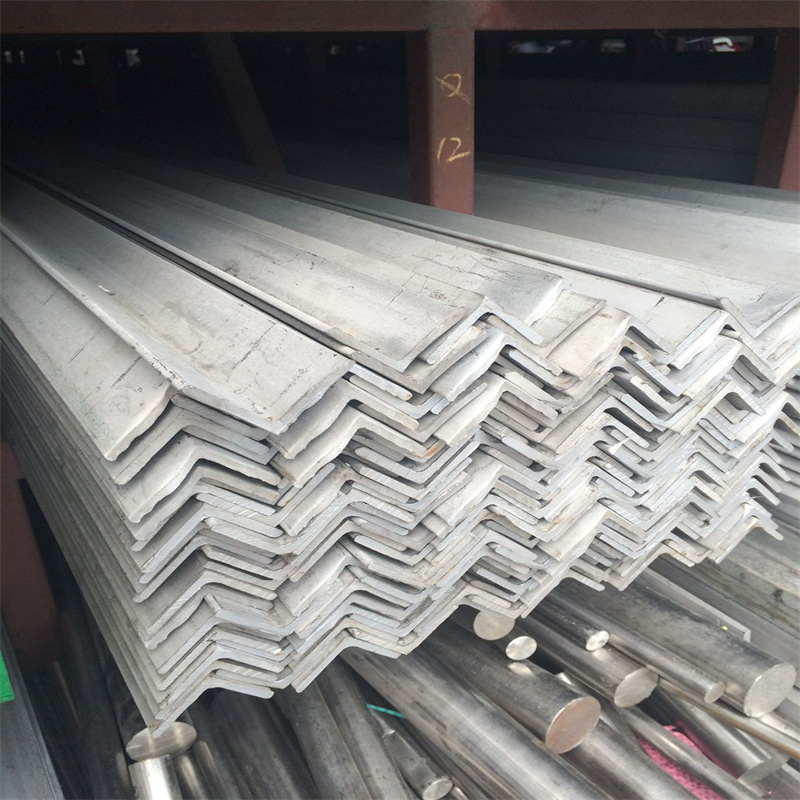

904L stainless steel angle steel

The 904L stainless steel angle bar, a high-performance metal product that offers exceptional strength and corrosion resistance. This grade of stainless steel, also known as 904L austenitic stainless steel, combines the best of both worlds: excellent mechanical properties with unmatched corrosion resistance.

904L stainless steel is austenitic, meaning it has a face-centered cubic crystal structure that ensures high levels of ductility, toughness, and tensile strength. This material is known for its excellent resistance to chloride stress corrosion cracking, making it an excellent choice for environments that are prone to chloride ion exposure.

The 904L stainless steel angle bar is a structural steel that offers a unique combination of form and function. Available in a range of sizes and shapes, it can be used in a variety of applications, including construction, industrial manufacturing, and even marine environments.

With its unique combination of corrosion resistance and mechanical properties, the 904L stainless steel angle bar offers a long service life and reduced maintenance requirements. It is also non-magnetic and suitable for high-temperature applications.

In terms of fabrication, the 904L stainless steel angle bar can be easily cut, bent, and welded into a variety of shapes and configurations. It bonds well with other materials and can be joined using traditional welding techniques.

In conclusion, the 904L stainless steel angle bar is the perfect metal solution for a wide range of demanding applications that require exceptional strength, corrosion resistance, and durability. It offers an excellent value proposition, combining high performance with cost-effectiveness, making it the metal of choice for many industrial and commercial projects.

| Chemical Composition | Carbon (C): 0.03 max Manganese (Mn): 2.00 max Phosphorus (P): 0.045 max Sulfur (S): 0.03 max Silicon (Si): 1.00 max Chromium (Cr): 24.0-26.0 min Molybdenum (Mo): 1.50-2.50 min Nickel (Ni): 3.00-5.00 max Copper (Cu): 1.50 max Nitrogen (N): 0.12 max |

| Mechanical Properties | Tensile Strength: 780-940 MPa Yield Strength: 480-680 MPa Elongation: 35-45% Hardness: Max 223 BHN |

| Physical Properties | Melting Point: 1350-1450°C Specific Gravity: 8.2 g/cm³ Thermal Conductivity: 16.2 W/m·K at 20°C Thermal Expansion: 12.6 μm/m·K at 20°C |

| Corrosion Resistance Properties | CASS Test: ASTM A763, 100 hr test with no pitting or crevice corrosion up to 65% neutral salt spray with a minimum of 95% retention of original finish.Wet Corrosion Resistance: Excellent resistance to chloride-ion stress corrosion cracking in both the sensitized and unsensitized condition. |