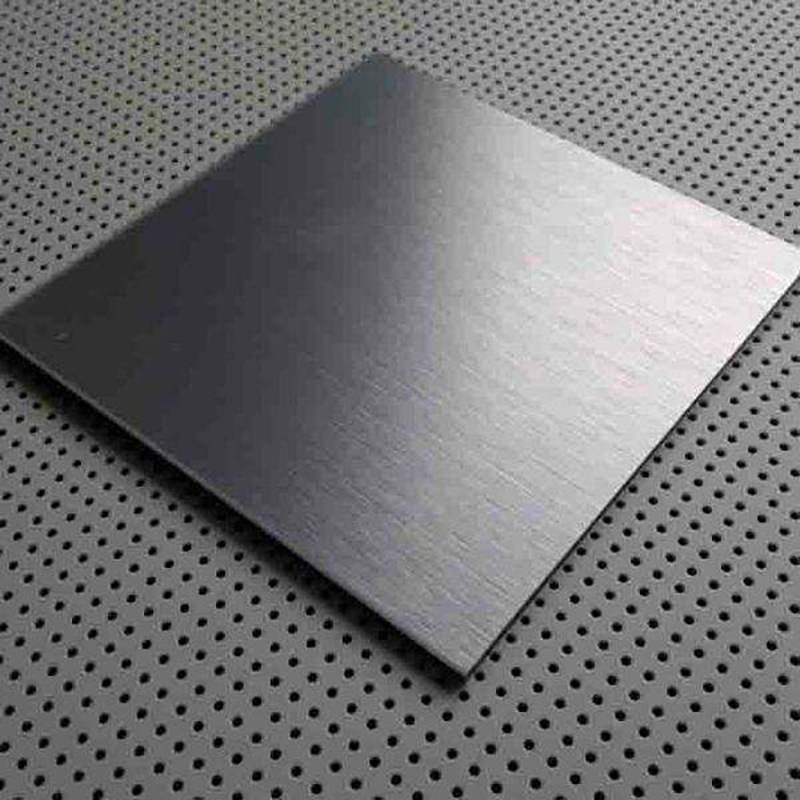

904L stainless steel brushed plate

The 904L stainless steel brushed plate is a premium-grade product known for its superior corrosion resistance, high strength, and excellent weldability. It finds extensive application in industries such as chemical processing, oil and gas, pharmaceuticals, and seawater desalination.

| Material | 904L Stainless Steel |

| Surface | Brushed finish |

| Thickness | Typically between 0.3mm and 3.0mm |

| Width | Usually ranges from 1000mm to 1500mm |

| Length | Customizable, up to six meters |

| Appearance | Brushed texture, creating a visually appealing and textured surface |

| Corrosion Resistance | Exceptional corrosion resistance in various harsh environments, including acids, chloride solutions, and high-temperature conditions |

| Applications | Chemical and petrochemical industries, pharmaceutical equipment, marine applications, food processing, heat exchangers, etc. |

| Chemical Composition | Carbon (C): ≤ 0.02% Silicon (Si): ≤ 1.00% Manganese (Mn): ≤ 2.00% Phosphorus (P): ≤ 0.045% Sulfur (S): ≤ 0.035% Chromium (Cr): 19.0 - 23.0% Nickel (Ni): 23.0 - 28.0% Molybdenum (Mo): 4.0 - 5.0% Copper (Cu): 1.0 - 2.0% |

904L Stainless Steel: This plate is manufactured using grade 904L stainless steel, which contains high levels of chromium, nickel, and molybdenum. These elements provide extraordinary resistance to corrosion, including pitting, crevice corrosion, and stress corrosion cracking.

Brushed Surface Finish: The plate undergoes a brushing process that imparts a visually appealing matte finish. The brushed surface not only enhances the aesthetic appeal but also helps to hide minor imperfections and scratches, ensuring a clean and professional appearance.

Exceptional Corrosion Resistance: The 904L stainless steel brushed plate offers exceptional resistance to a wide range of corrosive environments, including sulfuric acid, hydrochloric acid, and seawater. It is highly suitable for use in aggressive chemical processing plants, offshore platforms, and marine applications.

High Strength and Durability: With its high alloy content, the 904L stainless steel brushed plate exhibits superior strength and toughness. It can withstand heavy loads, impacts, and extreme temperature variations, ensuring long-term durability and reliability.

Excellent Weldability: The 904L stainless steel brushed plate demonstrates excellent weldability, allowing for easy fabrication and installation. It offers good formability and can be readily welded without compromising its corrosion resistance and mechanical properties.

Versatile Applications: This product finds widespread use in various industries due to its corrosion resistance and mechanical properties. It is utilized in applications such as heat exchangers, pressure vessels, tanks, piping systems, and other components that require both corrosion resistance and strength.

Easy Maintenance: The brushed surface finish on the plate requires minimal maintenance. Regular cleaning with mild detergents and non-abrasive cloths or sponges is sufficient to maintain its pristine appearance.

Environmental Considerations: Stainless steel, including 904L, is a sustainable material that can be recycled without degradation. Choosing the 904L stainless steel brushed plate promotes eco-friendly practices and reduces environmental impact.

In summary, the 904L stainless steel brushed plate offers exceptional corrosion resistance, high strength, and weldability. Its ability to withstand aggressive environments while maintaining its integrity makes it a reliable choice for various industries where durability, performance, and resistance to corrosion are critical.