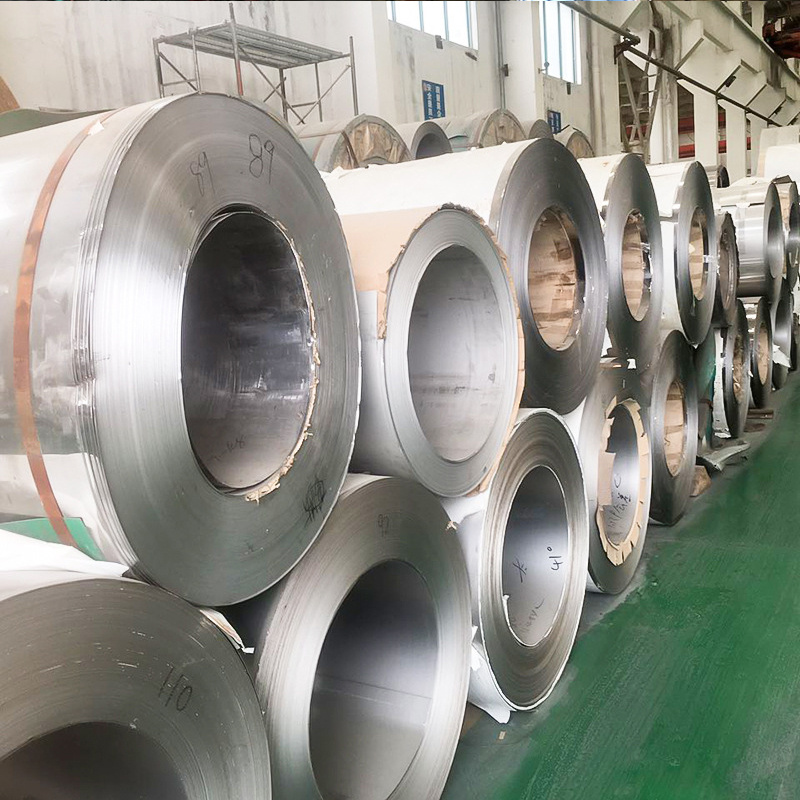

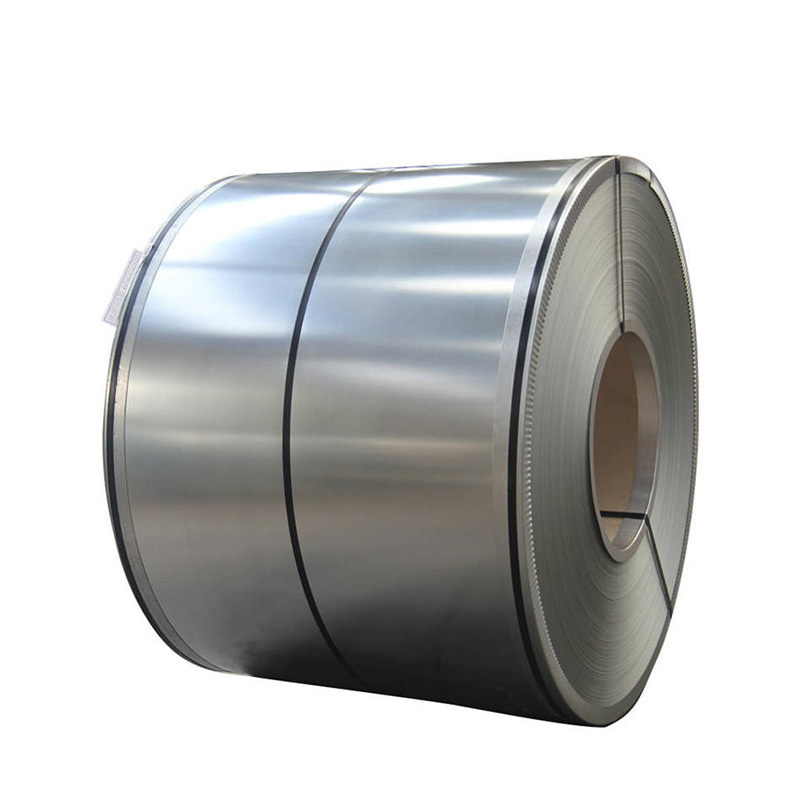

904L Stainless Steel Cold-Rolled Coils

904L stainless steel, a high-performance alloy, finds its application in a wide range of industries due to its exceptional corrosion resistance and exceptional mechanical properties. The cold-rolled coil of 904L stainless steel is a prime example of this material's adaptability and reliability.

| Stainless Steel Coil | |

| Standard: | ASTM,GB,JIS,AISI,EN,DIN |

| Grade: | 201/304/316L/310S/254/2205/2507/904L, etc. |

| Width(mm): | 1000/1219/1500/1800/2000mm or Customized |

| Thickness(mm): | Cold Rolled: 0.15mm-3.0mm |

| Surface: | No.1,No.3,No.4,TR,HL,2D,2B,BA,8K |

| Packing: | Standard Export Pack or Customized |

| Lead Time: | 7~14 days |

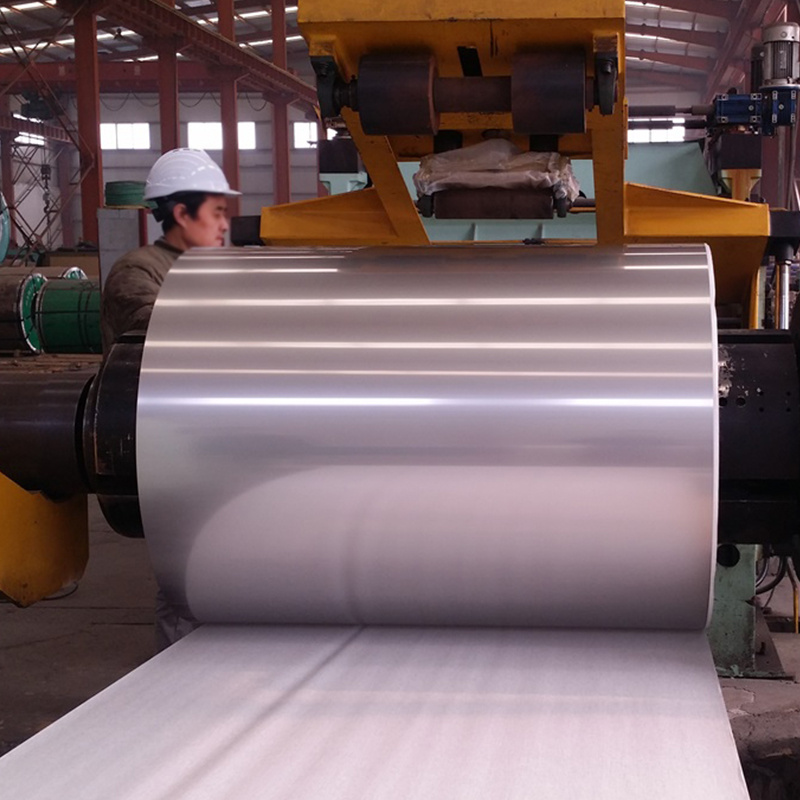

The production of 904L cold-rolled coil involves multiple processes, starting with the hot-rolled coil produced from a slab of 904L stainless steel. This hot-rolled coil is then annealed and pickled to remove impurities and scale, ensuring a clean surface for the cold rolling process. The cold rolling reduces the thickness of the coil, enhancing its strength and corrosion resistance. The final step involves the annealing and flattening process to ensure the desired flatness and surface quality of the coil.

904L stainless steel offers exceptional corrosion resistance due to its high nickel and molybdenum content, which also provides good resistance to chloride stress corrosion cracking. Its excellent mechanical properties, including high strength and ductility, make it an ideal material for a variety of applications.

The cold-rolled coil of 904L stainless steel finds its application in industries such as chemical processing, pharmaceutical manufacturing, food processing, and oil and gas. It is used in equipment and components that require high corrosion resistance, such as tanks, pipes, valves, and reactors. The material's exceptional properties also make it suitable for use in demanding environments, including seawater exposure and cryogenic temperatures.

In conclusion, the cold-rolled coil of 904L stainless steel offers an excellent combination of corrosion resistance, mechanical properties, and adaptability to various applications. Its use in various industries highlights its versatility and reliability in a range of challenging environments.