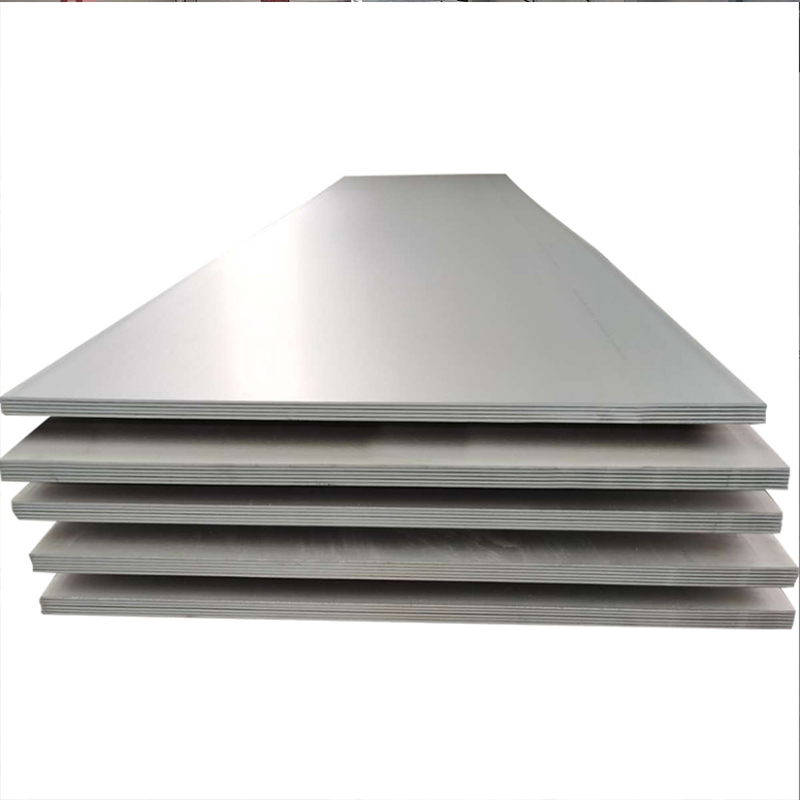

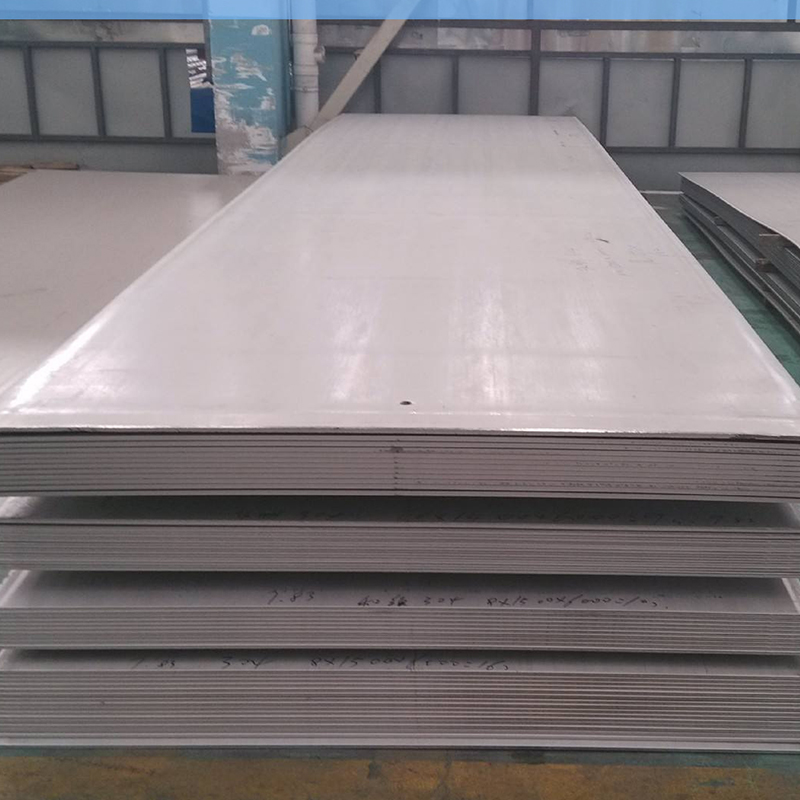

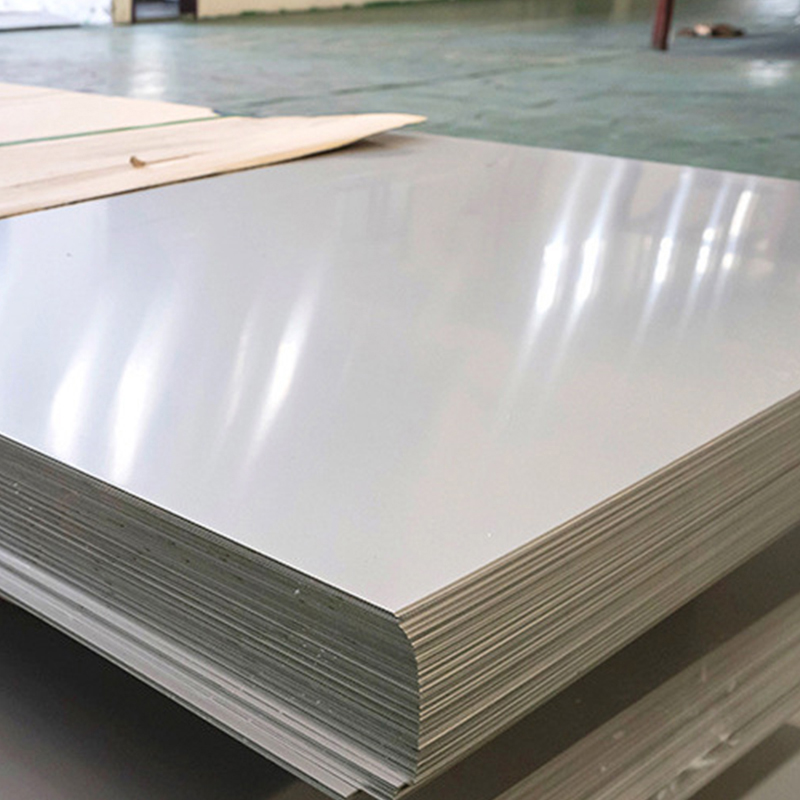

904L stainless steel cold rolled plate

904L stainless steel cold rolled plate is a high-performance and corrosion-resistant metal product. It belongs to the austenitic stainless steel family, known for its excellent formability, weldability, and toughness. This grade offers exceptional resistance to various corrosive environments, making it suitable for a wide range of applications.

| Grade | 904L |

| Manufacturing Method | Cold Rolled |

| Thickness Range | 0.5mm - 6mm |

| Width Range | Up to 2000mm |

| Length Range | Up to 6000mm |

| Surface Finish | 2B, BA, No.1, No.4, No.8, HL, etc. |

| Tensile Strength | ≥ 490 MPa |

| Yield Strength | ≥ 220 MPa |

| Elongation | ≥ 35% |

| Hardness (HB) | ≤ 220 |

| Density | 7.95 g/cm³ |

| Chemical Composition | Carbon (C): ≤ 0.02% |

| Silicon (Si): ≤ 1.00% | |

| Manganese (Mn): ≤ 2.00% | |

| Phosphorus (P): ≤ 0.045% | |

| Sulfur (S): ≤ 0.035% | |

| Chromium (Cr): 19.0 - 23.0% | |

| Nickel (Ni): 23.0 - 28.0% | |

| Molybdenum (Mo): 4.0 - 5.0% | |

| Copper (Cu): 1.0 - 2.0% |

Key features and advantages of 904L stainless steel cold rolled plate are as follows:

1.Superior corrosion resistance: The plate exhibits outstanding resistance to a wide range of corrosive media, including sulfuric acid, phosphoric acid, and chloride solutions. Its high chromium, nickel, and molybdenum content provides excellent resistance to pitting and crevice corrosion. This makes it highly suitable for use in chemical processing plants, pharmaceutical industries, and seawater environments.

2.High strength and toughness: 904L stainless steel cold rolled plate possesses excellent strength and toughness, allowing it to withstand heavy loads and impacts. This property makes it ideal for structural components, pressure vessels, and heat exchangers in industries such as oil and gas, petrochemical, and desalination plants.

3.Good formability and weldability: The plate exhibits good formability, enabling it to be easily shaped and fabricated into desired structures. It can be welded using various methods, including shielded metal arc welding, gas tungsten arc welding, and plasma arc welding. Its low carbon content minimizes the risk of carbide precipitation during welding, ensuring excellent joint integrity.

4.Excellent resistance to wear and abrasion: 904L stainless steel cold rolled plate offers superior resistance to wear and abrasion, making it suitable for applications subjected to mechanical stress and friction. This includes equipment parts, machinery components, and tools that require long-lasting durability.

5.Wide temperature range: The plate maintains its mechanical properties over a broad temperature range, from cryogenic temperatures up to elevated levels. This versatility allows its use in diverse applications, such as cryogenic storage tanks, heat exchangers, and furnace components.

904L stainless steel cold rolled plate is widely used in industries that require exceptional corrosion resistance, strength, and durability. It is important to consult with experts and consider specific project requirements when selecting 904L stainless steel cold rolled plate, ensuring optimal performance and longevity in your application.