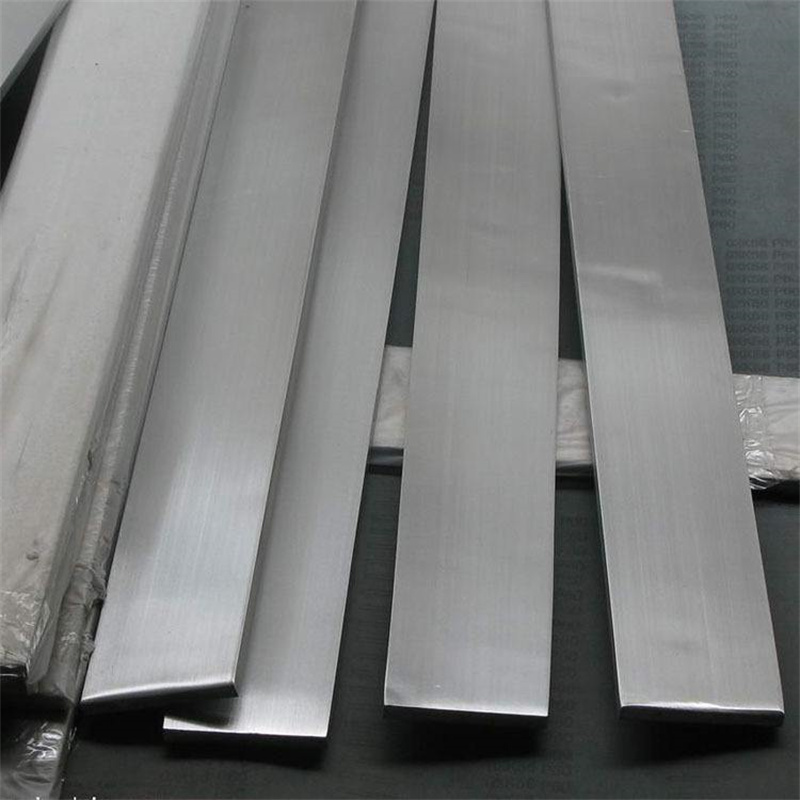

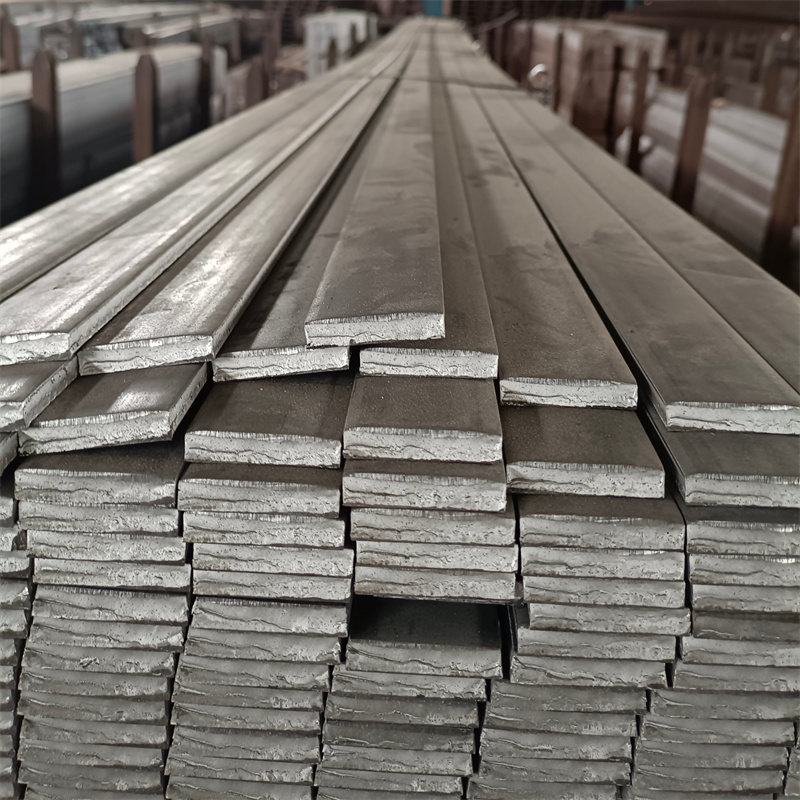

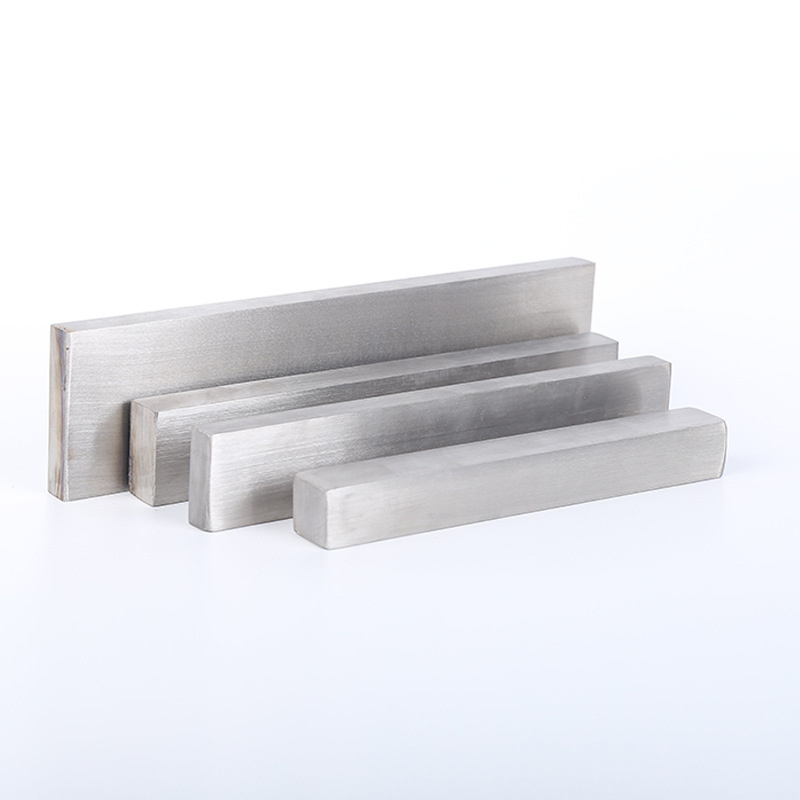

904L stainless steel flat steel

The 904L stainless steel flat bar, a high-performance metalwork solution for a range of industrial applications. This robust material offers exceptional corrosion resistance, making it an excellent choice for environments where exposure to harsh chemicals and challenging conditions is commonplace.

The 904L stainless steel flat bar is a grade of austenitic stainless steel, renowned for its exceptional corrosion resistance and high strength. It boasts a unique combination of properties that make it suitable for a wide range of industrial applications. With its high chromium and nickel content, the 904L stainless steel flat bar offers excellent resistance to corrosion, making it an excellent choice for use in environments where exposure to acids, alkalis, and other corrosive substances is commonplace.

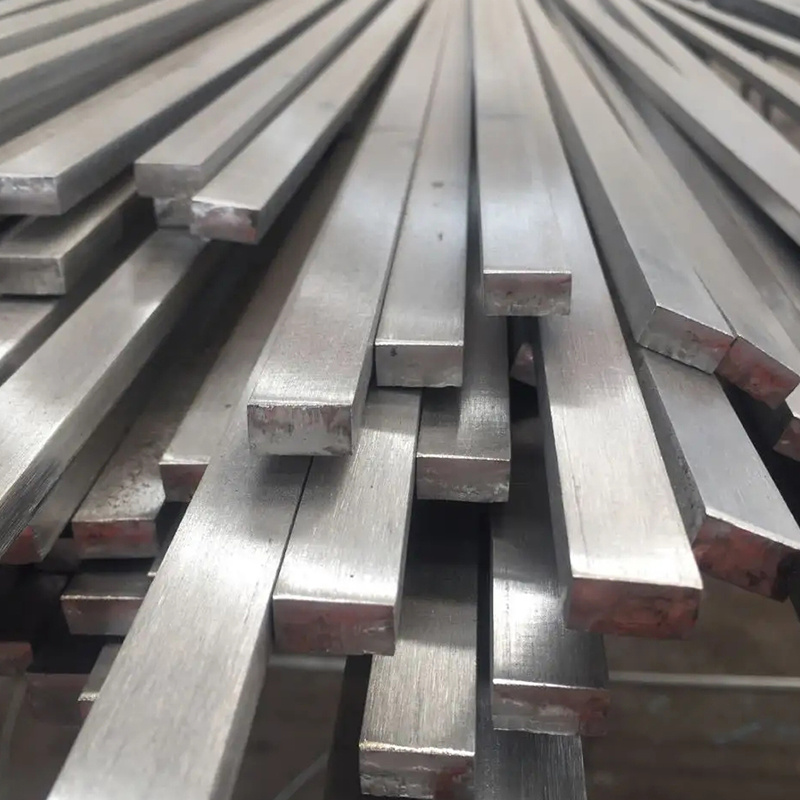

This grade of stainless steel flat bar also exhibits excellent mechanical properties, including high tensile strength and ductility. It can be easily bent and shaped, making it suitable for use in a variety of metalworking projects, such as the production of structural components, brackets, and other fabricated parts. The 904L stainless steel flat bar is also highly versatile and can be used in a range of industries, including chemical processing, food processing, and pharmaceutical manufacturing.

In addition to its corrosion resistance and mechanical properties, the 904L stainless steel flat bar also offers good formability and weldability. It can be easily welded using standard stainless steel welding techniques, making it suitable for use in assemblies and fabricated structures. The material is also compatible with a range of joining methods, such as soldering, brazing, and riveting.

When it comes to processing the 904L stainless steel flat bar, it is essential to follow best practices to ensure optimal performance and durability of the finished product. Proper heat treatment is essential to achieve the desired properties, and it is essential to control the cooling rate to prevent thermal cracking. It is also important to use quality tools and equipment to ensure accurate cuts and smooth finishes on the surface of the material.

In conclusion, the 904L stainless steel flat bar is an exceptional choice for industrial applications that require exceptional corrosion resistance, high strength, and good formability. Its unique combination of properties makes it suitable for use in a range of industries, and with proper processing and handling, it can deliver long-lasting performance in demanding applications.

| Product Name | 904L Stainless Steel Flat Bar |

| Material composition | Carbon (C): ≤ 0.030% Manganese (Mn): ≤ 2.00% Phosphorus (P): ≤ 0.030% Sulphur (S): ≤ 0.010% Chromium (Cr): 19.00-23.00% Nickel (Ni): 11.00-15.00% Molybdenum (Mo): 2.50-3.50% Silicon (Si): ≤ 1.00% Aluminum (Al): ≤ 0.35% Copper (Cu): ≤ 0.75% Titanium (Ti): ≤ 0.75% Zirconium (Zr): ≤ 0.75% Boron (B): ≤ 0.006% Other elements: W, Nb, Ta, Ce, Y, La ≤ 0.15% |

| Grade characteristics | High corrosion resistance Good tensile strength and yield strength Low temperature toughness Excellent weldability Resistant to most acids, alkalis, and organic solvents |

| Applications | Chemical processing equipment Marine environments Petroleum refining equipment Heat exchangers and pressure vessels Corrosion-resistant piping systems Food processing equipment Automotive components Biomedical equipment and implants |