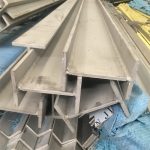

904L stainless steel H beam

Introduction:The 904L stainless steel H-section steel, also known as the H-beam or H-girder, is a versatile steel shape that offers exceptional strength and durability. Characterized by its H-shaped cross-section, it is widely used in a range of engineering and construction applications due to its exceptional resistance to corrosion and high tensile strength.

Properties:904L stainless steel is austenitic, non-magnetic, and has excellent resistance to both corrosion and heat. It offers higher strength properties compared to other stainless steels, making it an excellent choice for use in high-stress environments. The H-shaped design of the steel provides exceptional bending and torsional strength, making it suitable for use in a variety of structural applications.

Applications:The 904L stainless steel H-section steel is used in a range of industries, including construction, bridges, offshore platforms, and chemical processing plants. It is commonly used as a beam or girder in the construction of frameworks and is also suitable for use as a support structure in shipbuilding and offshore engineering. The corrosion resistance of 904L stainless steel makes it an excellent choice for use in corrosive environments such as coastal regions or industrial settings.

Production Process:The production of 904L stainless steel H-section steel involves several processes. First, the raw material undergoes hot rolling to shape the steel into its H-shaped cross-section. This is followed by annealing to ensure the steel has the desired mechanical properties. The surface of the steel is then polished or coated to enhance its corrosion resistance. Finally, the H-section steel is cut to length and inspected to ensure it meets the required quality standards.

Conclusion:The 904L stainless steel H-section steel offers exceptional strength, durability, and corrosion resistance, making it an ideal choice for a range of engineering and construction applications. Its H-shaped design provides exceptional bending and torsional strength, while the corrosion resistance of 904L stainless steel ensures longevity in even the most corrosive environments. The production process ensures that the H-section steel meets the highest quality standards, providing peace of mind for designers and engineers using this exceptional material.

904L stainless steel is a high alloy austenitic steel, which offers excellent corrosion resistance and good mechanical properties at elevated temperatures. It is commonly used in applications where high strength, durability, and corrosion resistance are required, such as in the chemical processing, pulp and paper, and power generation industries.

| Product Name | 904L Stainless Steel H-Beam |

| Composition | Carbon (C): 0.04% max Manganese (Mn): 2.00% max Phosphorus (P): 0.04% max Sulfur (S): 0.03% max Chromium (Cr): 18.00-21.00% Nickel (Ni): 8.00-11.00% Molybdenum (Mo): 2.00-3.00% Titanium (Ti): 5C-0.70% Aluminum (Al): 0.10-0.50% Silicon (Si): 1.00% max Copper (Cu): 1.00% max Zirconium (Zr): 0.15-0.50% Selenium (Se): 0.30% max Cobalt (Co): 0.50% max Silver (Ag): 0.50% max Boron (B): 0.001-0.01% Carbon Monoxide (CO): 0.25% max |

| Mechanical Properties | Tensile Strength: 695 MPa min Yield Strength: 345 MPa min Elongation: 35% min Impact Strength: 27 J max at -40°C Impact Strength: 47 J max at -196°C |