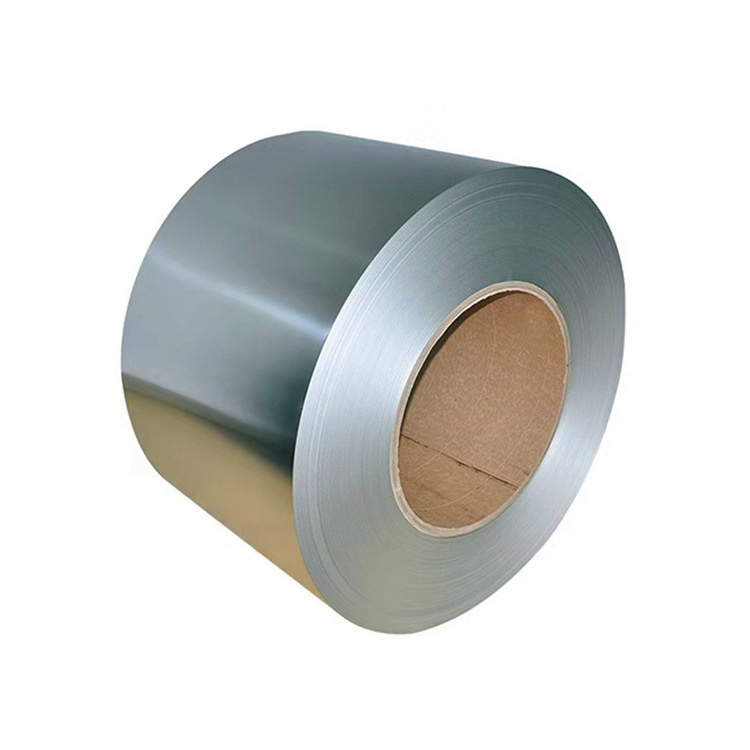

904L Stainless Steel Hot-Rolled Coils

The 904L stainless steel hot-rolled coil is a high-performance material, prized for its exceptional corrosion resistance and exceptional strength. This metal's unique properties make it suitable for a range of demanding applications.

| Stainless Steel Coil | |

| Standard: | ASTM,GB,JIS,AISI,EN,DIN |

| Grade: | 201/304/316L/310S/254/2205/2507/904L, etc. |

| Width(mm): | 1000/1219/1500/1800/2000mm or Customized |

| Thickness(mm): | Hot Rolled: 3.0mm-10.0mm or Customized |

| Surface: | No.1,No.3,No.4,TR,HL,2D,2B,BA,8K |

| Packing: | Standard Export Pack or Customized |

| Lead Time: | 7~14 days |

The production of hot-rolled coil begins with the heating of the steel to temperatures above 1700°F to ensure complete melting. The molten steel is then poured into large casting machines where it is formed into large ingots or slabs. These ingots are then reheated and rolled under high pressure to achieve the desired thickness and width. The final product, the 904L stainless steel hot-rolled coil, is wound into coils for easy transportation and storage.

904L stainless steel, an austenitic stainless steel, offers superior corrosion resistance due to its high chromium and nickel content. It also has excellent resistance to acids and alkalis, making it suitable for use in severe chemical environments. Additionally, 904L stainless steel has good mechanical properties, including high tensile strength and excellent formability.

The wide range of applications for 904L stainless steel hot-rolled coil includes the manufacturing of chemical processing equipment, oil and gas pipelines, medical equipment, and in the pulp and paper industry. Its corrosion resistance and strength make it an excellent choice for these applications where durability and longevity are essential.