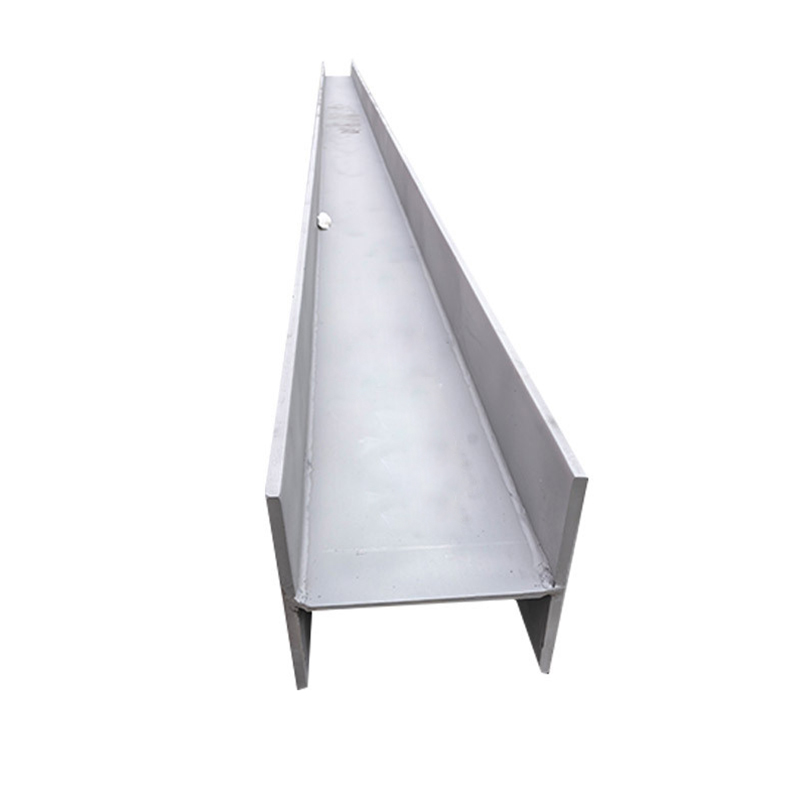

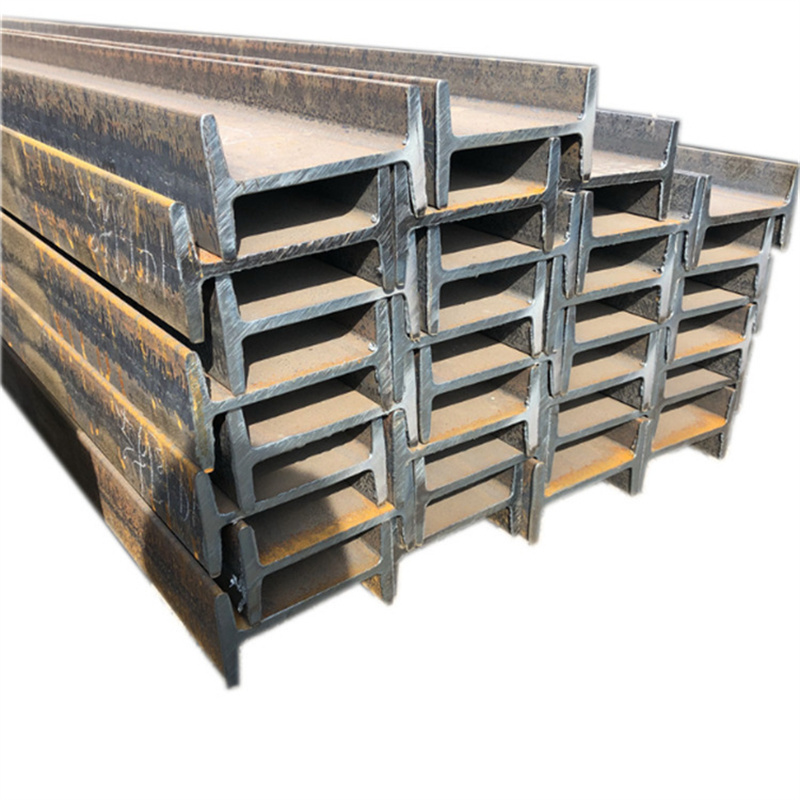

904L stainless steel i beam

2507 stainless steel i-beams are a high-performance structural material, renowned for its exceptional strength, corrosion resistance, and durability. This grade of stainless steel offers a unique combination of excellent mechanical properties and exceptional corrosion resistance, making it an ideal choice for a wide range of applications in both civilian and industrial sectors.

904L stainless steel is a highly alloyed material, combining exceptional tensile strength with incredible ductility. This unique combination ensures that our i beam can withstand even the most rigorous demands of your application, whether it's in the harshest of environments or under heavy loads. The corrosion resistance of this grade of stainless steel further enhances its durability, making it an excellent choice for both indoor and outdoor use.

The 904L stainless steel i beam has a wide range of potential applications. It can be used in the construction industry, where its superior strength and corrosion resistance make it an excellent choice for beams, columns, and other load-bearing components. It's also suitable for use in the transportation industry, where it can be used to make parts that require high durability, such as railings, bridges, and automobile components. Additionally, the 904L stainless stee li beam can be employed in the oil and gas industry, as it withstands high temperatures and harsh chemical environments.

The 904L stainless steel i beam is also an excellent choice for those working in the marine industry. Its corrosion resistance and strength make it well-suited for use in boat hulls, shipbuilding, and other underwater applications. It's even suitable for use in the food and beverage industry, as itComply with FDA standards and meet food safety requirements.Superior Performance

The 904L stainless steel i beam offers superior performance in a variety of settings. Its exceptional strength and ductility allow it to handle heavy loads without deformation, ensuring stability and reliability in your structure. The corrosion resistance of this grade of stainless steel ensures that your components will remain in good condition for longer, reducing the need for costly maintenance and repairs.

In addition to its exceptional physical properties, the 904L stainless steel i beam is also easy to fabricate and install. Its versatility allows for a range of finishes and treatments, ensuring that your beam will coordinate seamlessly with your existing materials and design aesthetic. The availability of this grade of stainless steel in a variety of standard and custom sizes further enhances its versatility, making it easy to find the perfect fit for your specific application.

In conclusion, the 904L stainless steel i beam is an innovative product that offers unparalleled strength, ductility, and corrosion resistance. Its adaptability and performance make it an excellent choice for a range of applications, from the construction industry to the marine industry. If you're looking for a reliable and durable structural component, the 940L stainless steel i beam should be your go-to choice.

| Product Name | 904L Stainless Steel I-Beams |

| Chemical composition | Element | Content (%) Carbon (C) | ≤ 0.030 Manganese (Mn) | ≤ 2.00 Phosphorus (P) | ≤ 0.035 Sulfur (S) | ≤ 0.015 Chromium (Cr) | 18.00 - 21.00 Nickel (Ni) | 3.00 - 5.00 Molybdenum (Mo) | 1.00 - 3.00 Silicon (Si) | ≤ 1.00 Titanium (Ti) | ≤ 0.75 Aluminum (Al) | ≤ 0.50 Nitrogen (N) | ≤ 0.10 |

| Mechanical Properties | Property | Value Tensile Strength (Yield Point, ksi) | ≥ 85 Tensile Strength (Ultimate, ksi) | ≥ 115 Elongation (%) | ≥ 25 Reduction of Area (%) | ≥ 45 Hardness (Rockwell C Scale) | ≤ 115 |

The above information provides a general overview of the chemical composition and mechanical properties of 904L stainless steel I-beams. It is essential to note that the actual properties may vary slightly depending on the specific manufacturing process and heat treatment used. Therefore, it is recommended to consult the manufacturer's datasheet or technical specification for detailed information on the material properties specific to the grade and application requirements.