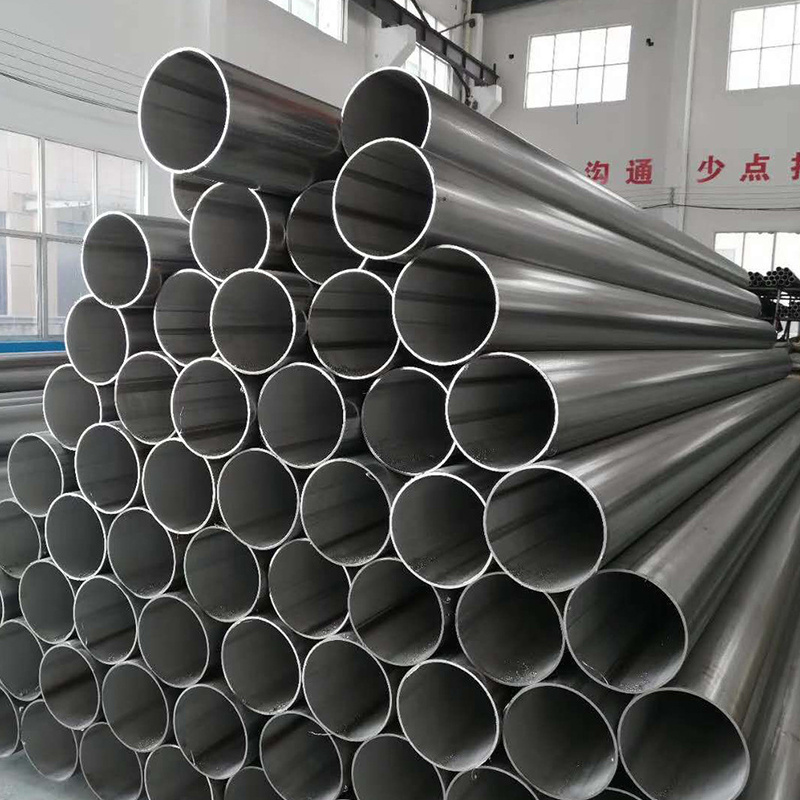

904L Welded Pipe

The 904L welded pipe is a high-alloy super-austenitic stainless steel pipe, primarily composed of 25% nickel, 20% chromium, and 4.5% molybdenum. It also contains small amounts of copper and carbon. The 904L welded pipe offers excellent corrosion resistance and mechanical properties, making it suitable for various demanding environmental applications.

Excellent corrosion resistance: The 904L welded pipe exhibits outstanding corrosion resistance in a wide range of corrosive media, including sulfuric acid, other strong acids, hydrochloric acid, chloride solutions, and seawater. It has exceptional resistance to stress corrosion cracking and intergranular corrosion.

High strength: Due to its super-austenitic structure, the 904L welded pipe possesses good strength and toughness. It can withstand higher pressure under high-temperature and high-pressure environments.

Excellent processability: The 904L welded pipe is easy to process, cold form, and hot form, suitable for various manufacturing and processing methods. It also has good weldability, allowing it to be connected and processed using common welding techniques.

Non-magnetic: The 904L welded pipe is non-magnetic, making it particularly useful in specific applications such as medical equipment and electronic devices.

Wide range of applications: The 904L welded pipe finds extensive applications in industries such as chemical, petroleum, pharmaceutical, marine engineering, and gas industry. It can be used in pipeline systems handling corrosive media, pressure vessels, heat exchangers, storage tanks for acidic environments, and high-temperature/high-pressure equipment.

In summary, the 904L welded pipe is a high-quality super-austenitic stainless steel pipe with excellent corrosion resistance, high strength, and good processability. It is suitable for use in various demanding environmental conditions.

Chemical Processing: Suitable for handling corrosive fluids and aggressive chemicals in chemical plants.

Oil and Gas Industry: Used in offshore platforms, pipelines, and subsea equipment due to its corrosion resistance and high strength.

Pharmaceutical Industry: Ideal for pharmaceutical manufacturing processes requiring high purity and corrosion resistance.

Marine Engineering: Used in seawater systems, desalination plants, and marine structures where corrosion resistance is crucial.

Other Industries: The 904L welded pipe finds applications in various industries requiring a combination of high corrosion resistance, strength, and processability.

Please note that the specifications may vary depending on the specific manufacturer or supplier. It is always recommended to refer to the product datasheet or contact the manufacturer for precise product information.

| Material | Super-Austenitic Stainless Steel (904L) |

| Size Range | Outer Diameter: [Specify the range] Wall Thickness: [Specify the range] Length: [Specify the standard length or custom length options] Standard: [Specify the applicable industry standards, such as ASTM, ASME, EN, etc.] |

| Chemical Composition | Nickel (Ni): 25% Chromium (Cr): 20% Molybdenum (Mo): 4.5% Copper (Cu): [Specify the copper content] Carbon (C): [Specify the carbon content] Other alloying elements: [Specify any other relevant alloying elements and their composition] |

| Mechanical Properties | Yield Strength: [Specify the minimum value in MPa or ksi] Tensile Strength: [Specify the minimum value in MPa or ksi] Elongation: [Specify the minimum value as a percentage] |

| General Corrosion | The 904L welded pipe exhibits excellent resistance to general corrosion in various corrosive media, including sulfuric acid, hydrochloric acid, and chloride-containing solutions. |

| Pitting and Crevice Corrosion | It offers high resistance to pitting and crevice corrosion, even in aggressive environments like seawater. |

| Stress Corrosion Cracking (SCC) | The 904L welded pipe has exceptional resistance to stress corrosion cracking caused by chlorides and other corrosive agents. |

| Welding Methods | The 904L welded pipe can be effectively welded using common welding techniques, such as TIG (GTAW), MIG (GMAW), and SMAW. |

| Welding Consumables | [Specify the recommended welding consumables, including filler materials and shielding gases, if applicable] |