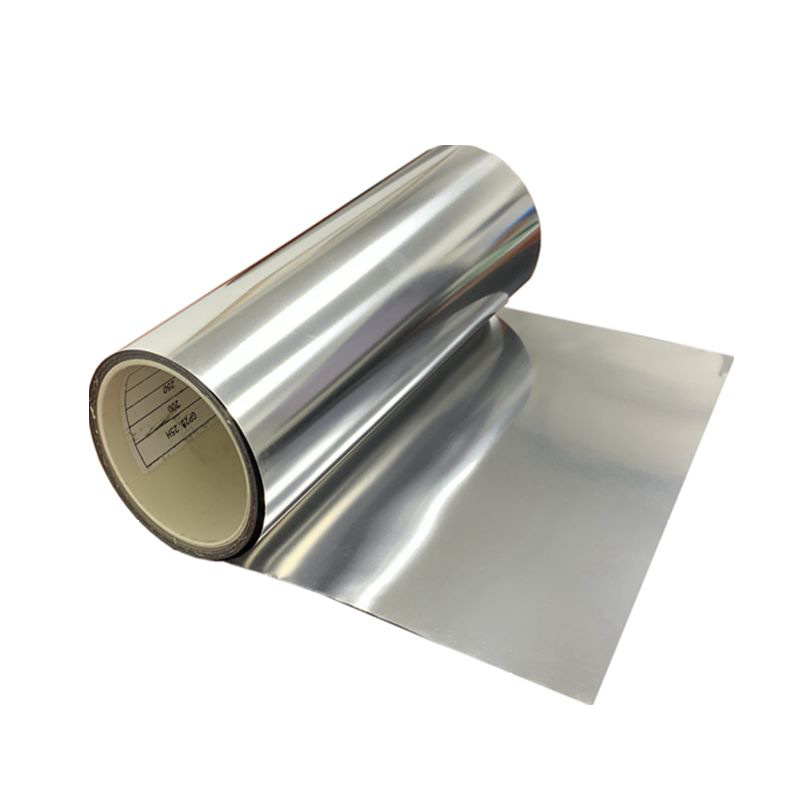

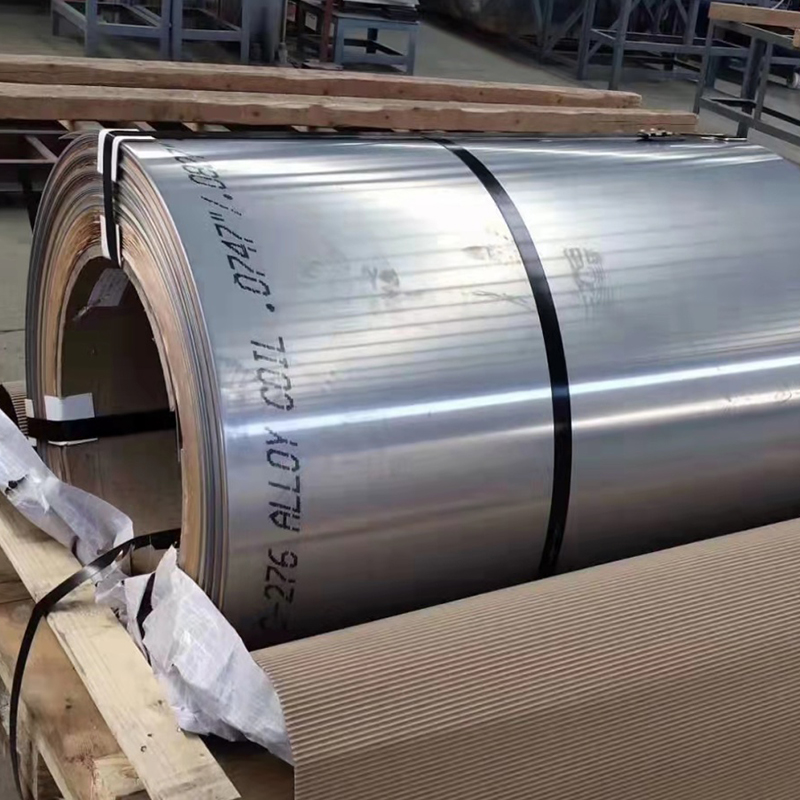

GH3030 coil

GH3030 coil is a high-performance nickel-based superalloy, renowned for its exceptional resistance to high temperatures and corrosion. It is widely used in a range of demanding applications, including aerospace, energy, and chemical processing industries.

GH3030 coil offers exceptional tensile strength and fatigue properties, making it an excellent choice for applications where strength and durability are paramount. It also has good resistance to oxidation and corrosion, making it suitable for use in harsh environments where exposure to high temperatures and corrosive agents is common.

The unique combination of properties found in GH3030 coil makes it suitable for a variety of applications. It is commonly used in the production of components for aircraft engines, such as turbine blades and vanes. In the energy industry, it is employed in the manufacture of components for power plants, including boiler tubes and heat exchangers. In the chemical processing industry, GH3030 coil finds use in the production of equipment exposed to corrosive chemicals.

The manufacturing process of GH3030 coil is crucial to ensuring its high-performance characteristics. The alloy is typically processed using powder metallurgy or casting techniques, followed by heat treatment and hot working. The final product is then inspected to ensure it meets the required mechanical and physical properties.

GH3030 coil is also available in a variety of forms, including sheet, plate, bar, and wire, to meet specific application needs. It can be further processed by machining, welding, and other fabrication techniques to create complex components with exacting tolerances and surface finishes.

In conclusion, GH3030 coil offers a unique combination of high-temperature resistance, corrosion resistance, and mechanical properties that make it an excellent choice for a range of demanding applications. Its adaptability and reliability make it a valuable addition to the toolbox of engineers and designers working in industries where performance and durability are paramount.

| Product Name: GH3030 coil |

| Chemical Composition |

| Ni | Cr | Co | Mo | Ti | Al | C | P | S | Fe | Cu |

| ≥52.0% | ≥19.0% | 10%-12% | 2%- 3% | 0.5%-1% | ≤0.5% | ≤0.08% | ≤0.02% | ≤0.015% | ≤18.0% | ≤0.5% |

| Mechanical Properties | GH3030 Coil exhibits excellent tensile strength, creep resistance, and fatigue strength. Typical tensile strength values range from 980 to 1370 MPa, depending on the annealing temperature and processing history. The alloy also exhibits good cold workability and can be processed through various forming operations. |

| Corrosion Resistance | GH3030 Coil offers excellent resistance to oxidation and corrosion in high-temperature environments. It is highly resistant to acids, alkalis, and other corrosive media. The alloy's protective oxide scale provides excellent durability in harsh environments. |

| Thermal Stability | GH3030 Coil maintains its mechanical properties at elevated temperatures, making it suitable for use in continuous service at temperatures up to 1100°C. The alloy exhibits good thermal stability and resistance to thermal fatigue cracking. |

| Processing and Fabrication | GH3030 Coil can be processed through conventional techniques such as melting, casting, hot and cold working, and joining operations. It is amenable to various welding processes and can be joined using common welding techniques. Fabrication of GH3030 Coil components requires careful attention to temperature control and heating rates to prevent cracking and other metallurgical issues. |

| Applications | GH3030 Coil is widely used in aerospace, power generation, petrochemical processing, and other industries that require high-temperature resistance and corrosion resistance. It is commonly used in components such as gas turbine blades, nozzles, combustion chambers, rocket propulsion systems, and other critical applications where high performance is essential. |