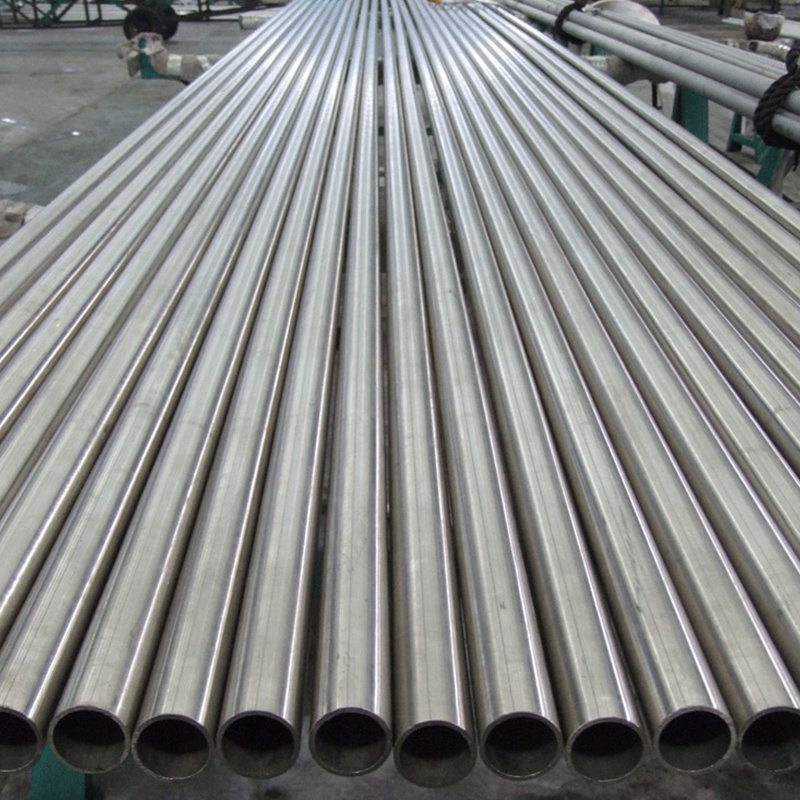

GH3030 Pipe

GH3030 Pipe, a high-performance austenitic nickel-chromium alloy pipe, finds applications in a range of industries where exceptional corrosion resistance and exceptional high-temperature strength are required. With its unique combination of properties, GH3030 Pipe has become a go-to material for demanding applications in the chemical processing, oil and gas, and power generation industries.

GH3030 Pipe is a solid solution-strengthened nickel-base alloy that offers excellent oxidation resistance at high temperatures. It contains significant amounts of chromium and aluminum, which contribute to its exceptional corrosion resistance. The addition of titanium and zirconium further enhances the alloy's high-temperature strength and stability.

High Temperature Strength: GH3030 Pipe offers excellent creep strength at elevated temperatures, making it suitable for use in extreme high-temperature environments.

Corrosion Resistance: The alloy's high chromium content provides resistance to a variety of corrosive environments, including acids, salts, and oxidizing agents.

Good Weldability: GH3030 Pipe can be easily welded, making it suitable for fabricating complex components and assemblies.

Ductility and Impact Resistance: The alloy exhibits good ductility and impact resistance at cryogenic temperatures, making it suitable for cryogenic applications.

Thermal Stability: GH3030 Pipe maintains its mechanical properties across a wide range of temperatures, making it suitable for use in cyclic heating and cooling applications.

GH3030 Pipe is used in a range of industries where its unique combination of properties is required:

Oil and Gas: In the oil and gas industry, GH3030 Pipe is used in the production, transportation, and processing of crude oil and natural gas. It is commonly used in pipelines, flowlines, and other critical components exposed to corrosive environments and high temperatures.

Chemical Processing: In the chemical processing industry, GH3030 Pipe is used in reactors, heat exchangers, and other critical equipment that require exceptional corrosion resistance and high-temperature strength.

Power Generation: In the power generation industry, GH3030 Pipe is used in the construction of boilers, turbines, and other components that require high-temperature strength and good oxidation resistance.

Aerospace and Defense: GH3030 Pipe is also used in the aerospace and defense industries for components that require high-temperature strength and corrosion resistance in extreme environments.

In conclusion, GH3030 Pipe is a high-performance nickel-base alloy that offers exceptional corrosion resistance, high-temperature strength, and good ductility. Its unique combination of properties makes it suitable for use in demanding applications across multiple industries, including oil and gas, chemical processing, power generation, aerospace, and defense.

| Product Name: GH2132 Pipe |

| Ni | Cr | Co | Mo | Ti | Al | C | P | S | Fe | Cu |

| ≥52.0% | ≥19.0% | 10%-12% | 2%- 3% | 0.5%-1% | ≤0.5% | ≤0.08% | ≤0.02% | ≤0.015% | ≤18.0% | ≤0.5% |

| GH3030 pipe is produced by vacuum melting and ingot casting, and then hot rolling and cold rolling to meet the requirements of different thickness and diameter. The wall thickness range is generally 3-60mm, and the diameter range is generally ≥48mm. |

|

| Mechanical Properties |

Tensile strength at room temperature: ≥539MPa |

| Yield strength at room temperature: ≥217MPa | |

| Ultimate elongation at room temperature: ≥30% | |

| Elastic modulus at room temperature: 188-219GPa | |

| Thermal expansion coefficient (20-100℃): 12.8 × 10-6/℃ | |

| Thermal conductivity (20℃): 14.3 W/m·K | |

| Electrical resistivity (20℃): ≥1.10μΩ·m | |

| Coefficient of thermal expansion (20-1100℃): (14-16.5) × 10-6/℃ | |

| Coefficient of thermal conductivity (20-1100℃): (14.7-15.9) W/m·K | |

| Thermal shock resistance (125℃ -20℃): ≥50 | |

| Times Long-term use temperature: ≤750℃ | |

| Application scope | Aerospace, chemical, and other industries that require high-temperature corrosion resistance. |